Contactor

A technology of contactors and contact bridges, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of unfavorable modular production, bulky contactors, and low assembly efficiency, and achieve ingenious connection structure, small size, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

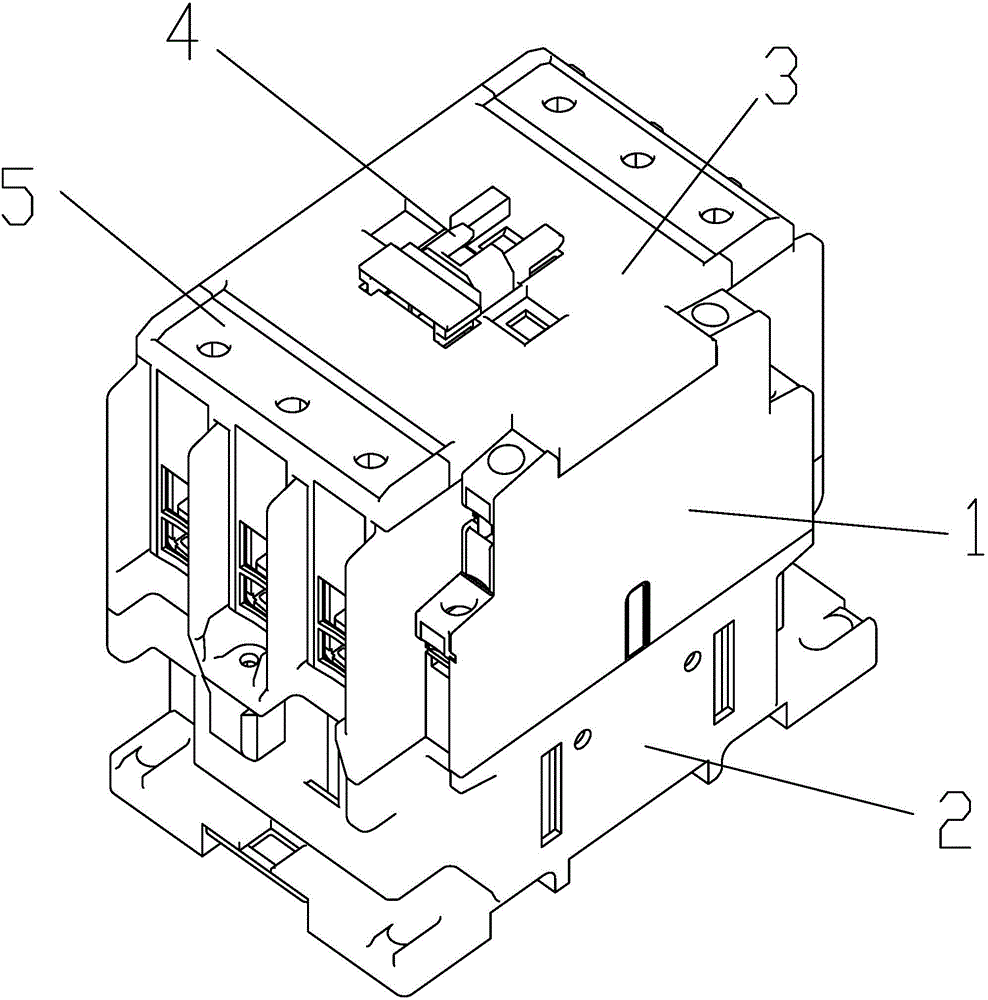

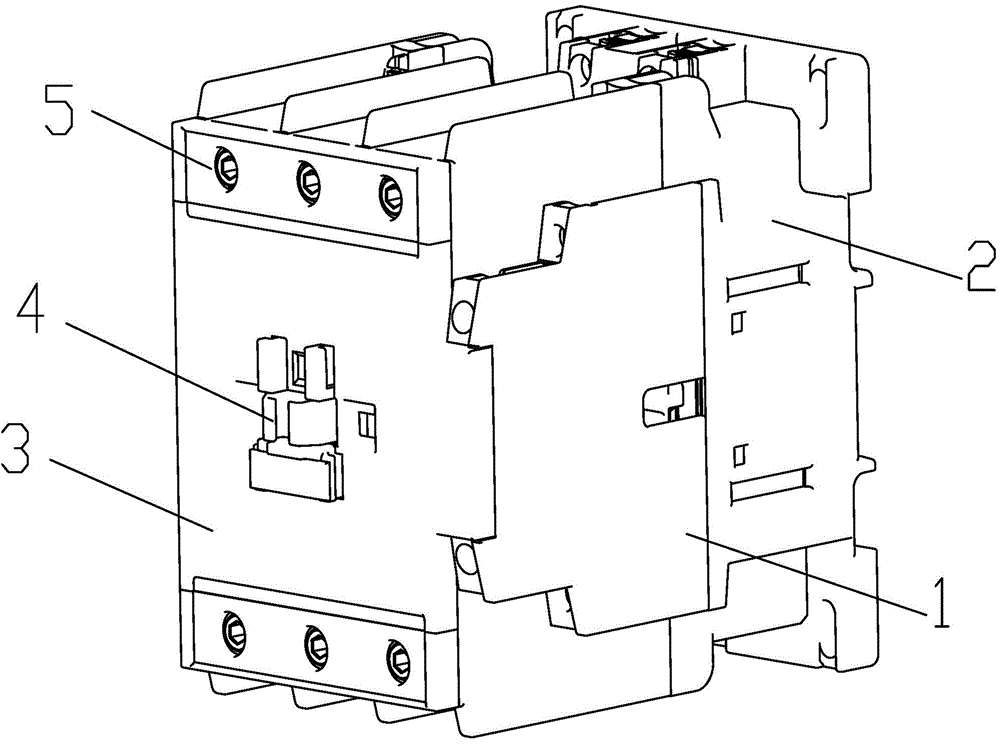

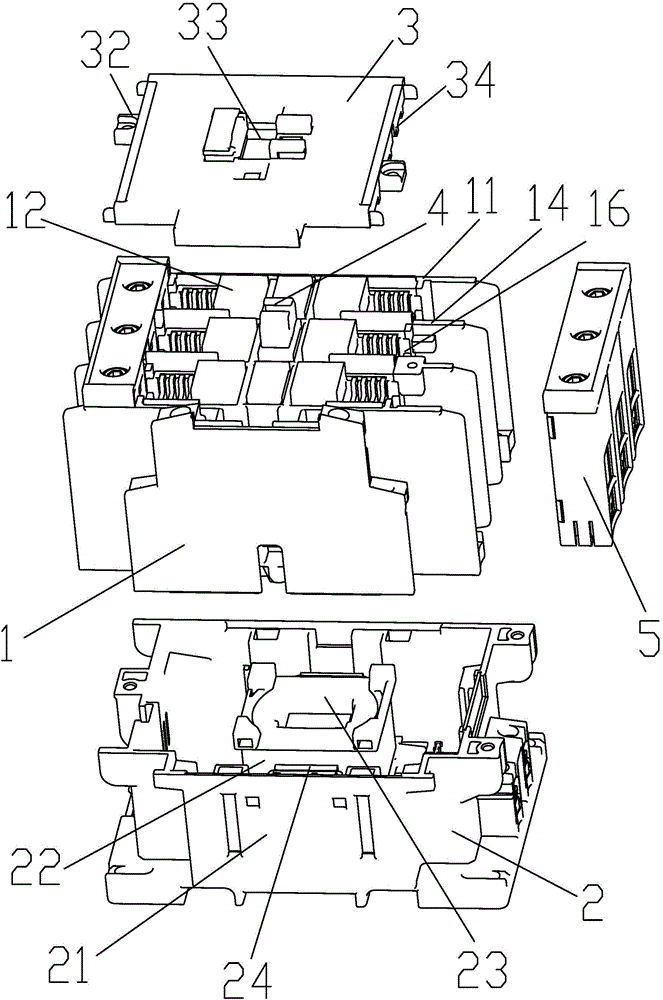

[0024] The following is attached Figures 1 to 4 The given examples further illustrate the specific implementation of the contactor of the present invention. The contactor of the present invention is not limited to the description of the following embodiments.

[0025] Such as Figure 1-4 As shown, the contactor of the present invention includes a base assembly 2 , a base assembly 1 and a top cover 3 , the base assembly 1 is fixedly connected to the base assembly 2 , and the top cover 3 is fixedly connected to the base assembly 1 . The base assembly 2 includes a base 21 and an electromagnet 22 disposed in the base 21 , the electromagnet 22 includes a coil 23 and a fixed iron core 24 . The base assembly 1 includes a base 11, a contact assembly 13 arranged in the base 11, an arc extinguishing unit 12 and a contact support 4; pole separators 14 are provided on both sides of the base 11 to accommodate each pole The unit cavity 16 of the conductive system, each unit cavity 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com