Conversion type electricity saving appliance

A power-saving and conversion technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high motor power, poor power-saving effect, and high power consumption, and achieve good use stability, simple structure, and energy saving. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

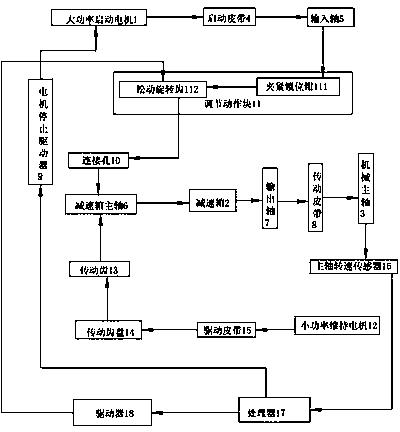

[0011] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0012] See figure 1 , a conversion type power saver, including a high-power starting motor 1, a reduction box 2 and a mechanical main shaft 3, the high-power starting motor 1 is connected with the input shaft 5 of the reduction box 2 through a starting belt 4, and the input The shaft 5 is coaxially connected with the reduction box main shaft 6 of the reduction box 2, the output shaft 7 of the reduction box 2 is connected with the mechanical main shaft 3 through a transmission belt 8, and the end of the reduction box main shaft 6 is provided with There is a connecting hole 10 coaxially arranged, and an adjusting action block 11 is arranged in the connecting hole 10, and the input shaft 5 is inserted into the connecting hole 10 and fixed coaxially with the reduction box main shaft 6 through the adjusting action block 11, Also be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com