Cyclic utilization method of three-dimensional printing products

A three-dimensional printing and product technology, which is applied in the field of recycling of three-dimensional printed products, can solve the problems of incomplete workpieces, high possibility of defective products, and increased destruction costs, so as to improve production efficiency and save the effect of pre-processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

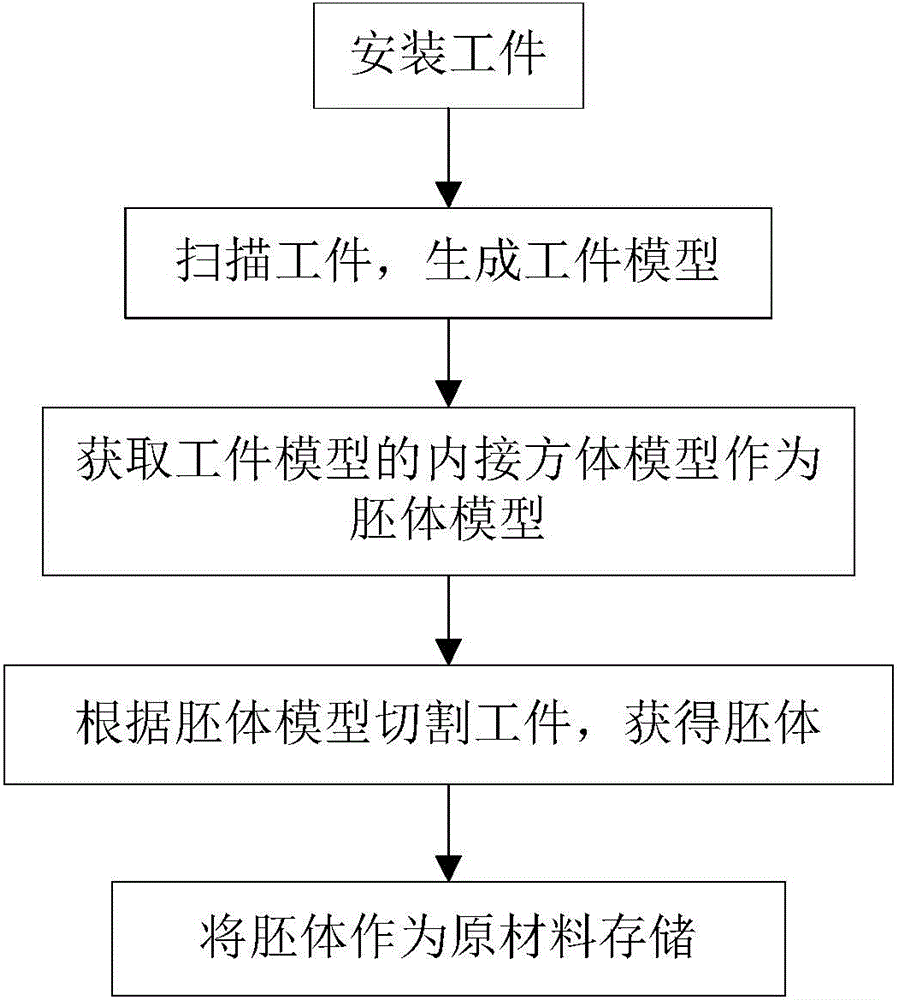

[0015] Such as figure 1 As shown, the present invention proposes a method for recycling 3D printed products, which involves cutting the surface of a 3D printed product to obtain an embryo body with a square structure, and storing the embryo body as a raw material.

[0016] This method specifically comprises the following steps:

[0017] S1. Install the 3D printing product to be processed as a workpiece.

[0018] The stability of the workpiece installation is directly related to whether the follow-up operation can be carried out stably and reliably.

[0019] S2. The scanner is set to scan the workpiece, and a workpiece model is generated according to the scanned data.

[0020] S3. Perform image processing on the workpiece model, and obtain an inscribed cube model of the workpiece model as an embryo body model.

[0021] In step S3, the specific method of obtaining the inscribed cube model of the workpiece model is: preset N cube models of different sizes according to the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com