Three-node compensating device for wire rope sets of elevator

The technology of a force equalizing device and a steel wire rope is applied in the field of the force equalizing device of a steel wire rope group for an elevator, and can solve the problems of damage, elevator safety accident, wire rope breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

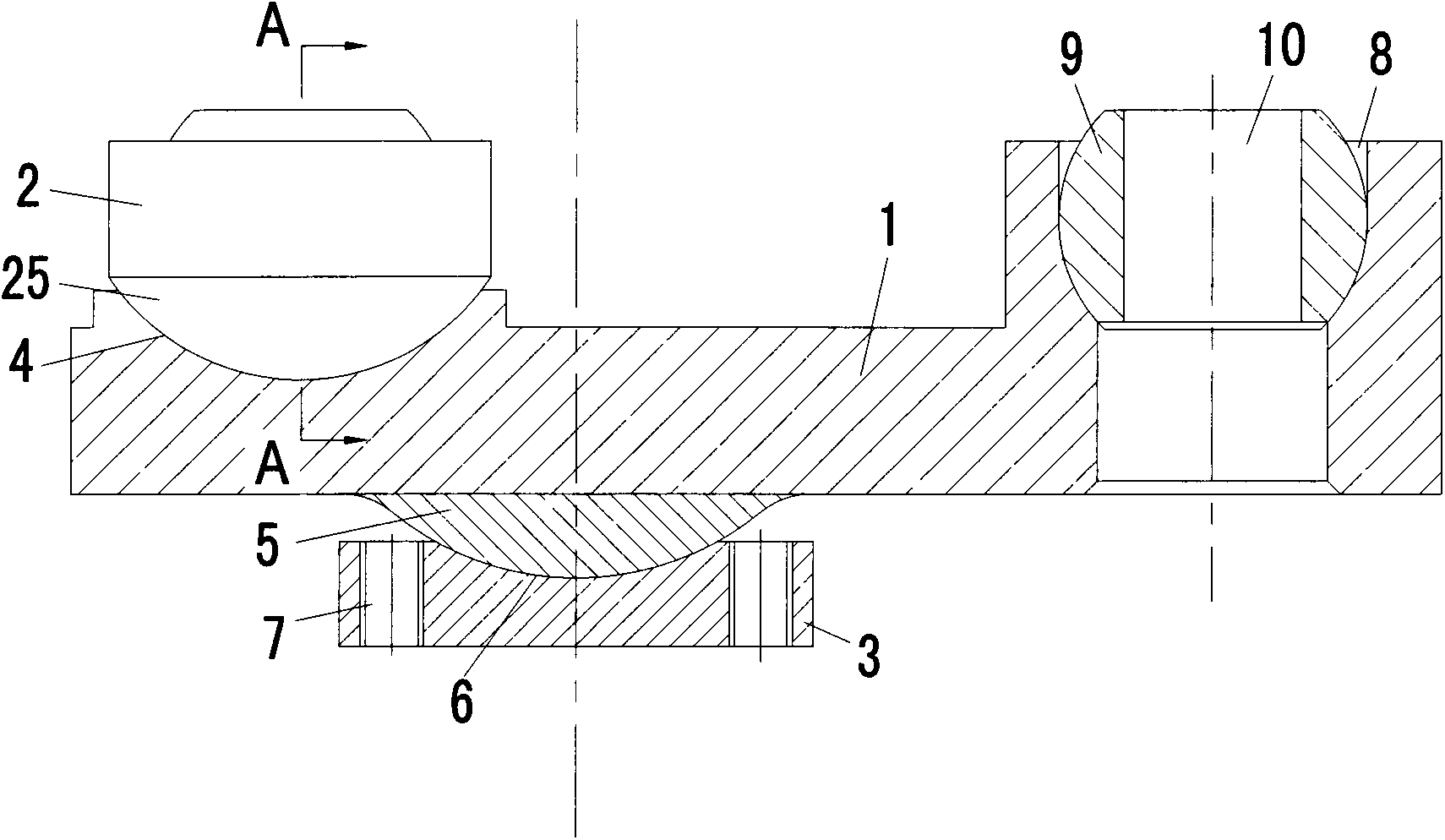

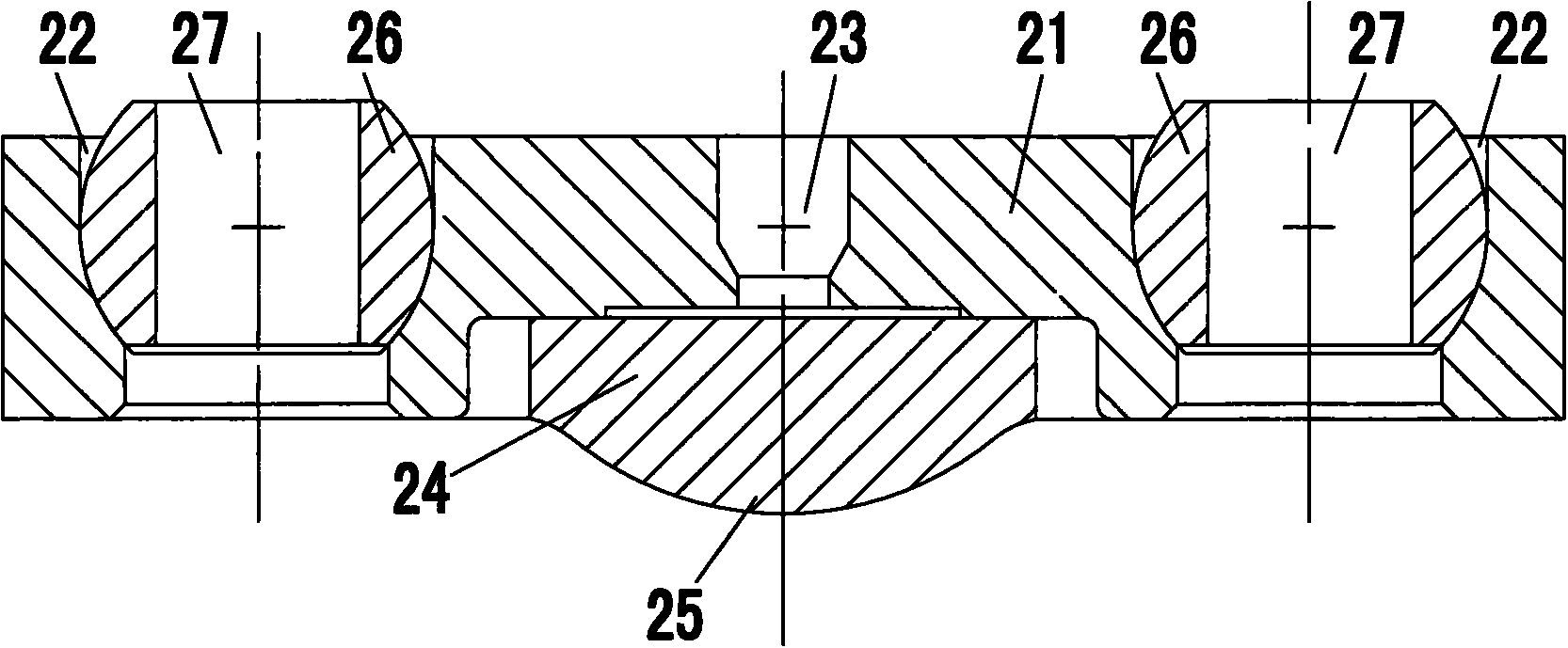

[0017] attached figure 1 , 2 It is a three-node force equalizing device for a steel wire rope set for an elevator according to the present invention, including a balance base 1 and a two-node force equalization assembly 2; the balance base 1 is rotatably arranged on a base 3; The force assembly 2 is rotatably arranged at one end of the balance seat 1; the other end of the balance seat 1 is provided with a first spherical node 9; the first spherical node 9 can rotate around the balance seat 1; the first spherical node The center of 9 is provided with a first through hole 10; the first through hole 10 is used to install a steel wire rope (not shown); the 2-node equalizing component 2 is symmetrically arranged with 2 second Spherical node 26; the center of rotation of the 2-node equalizing assembly 2 is located on its center plane; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com