Pre-beating device of carbon fiber multi-layer angle knitting machine

An angle-linked loom, carbon fiber technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of carbon fiber wear, affecting the quality of the cloth, and defects on the cloth, so as to reduce losses, facilitate popularization and application, and occupy The effect of less ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

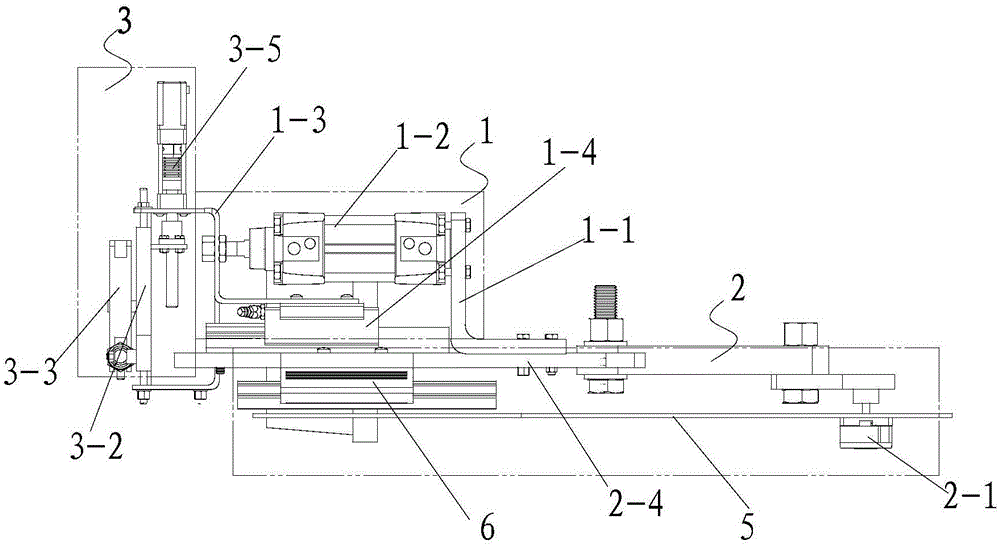

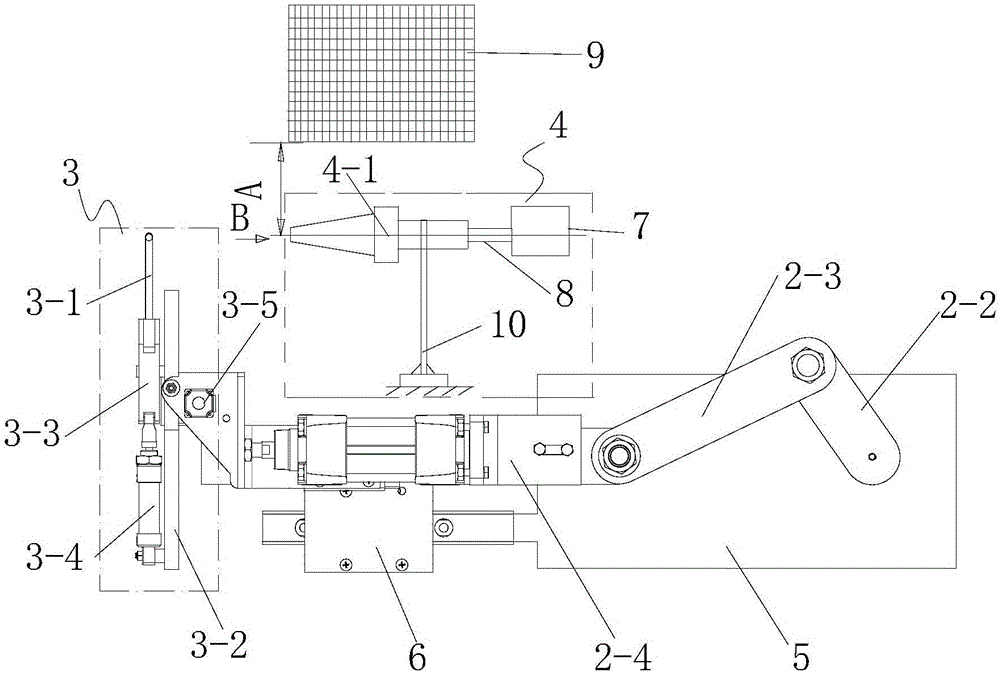

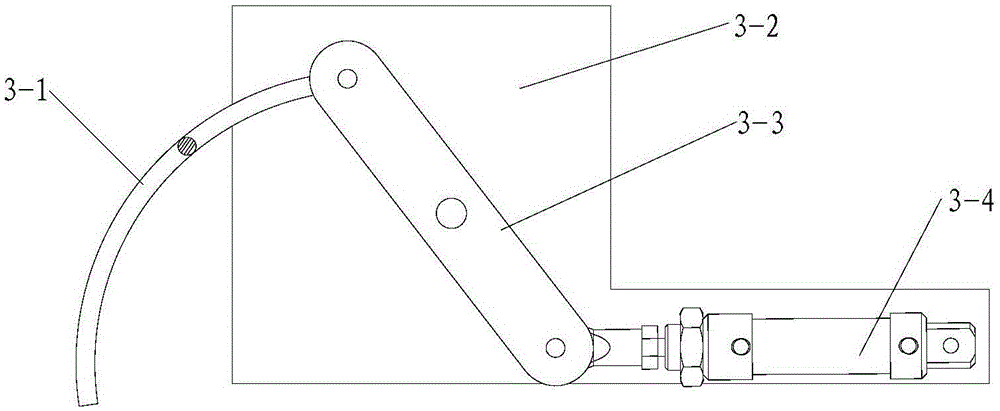

[0020] Referring to the accompanying drawings for details, the present invention provides a pre-beating-up device for a carbon fiber multi-layer angle knitting machine, including a negative pressure suction nozzle mechanism, a swing hook mechanism, and a crank slider weft feeding mechanism 2, and the crank slider weft feeding mechanism 2 Mechanism comprises stepping motor 2-1, crank 2-2, crank connecting rod 2-3 and slider moving plate 2-4, and described stepping motor is fixed on the connecting plate 5, and described stepping motor output shaft and crank One end is keyed, the other end of the crank is pinned to the crank connecting rod, the other end of the crank connecting rod is pinned to the slider moving plate, and the slider moving plate is fixedly connected to the first linear slide rail 6; the swing The crochet hook mechanism 3 comprises a stepping ball screw mechanism 3-5, a lift moving plate 3-2, a limit cylinder 3-4, a cylinder connecting rod 3-3 and a semicircle cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com