A large bridge bearing grouting formwork

A bridge bearing and formwork technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction, complicated operation, axis and plane elevation errors, etc., achieve high construction control accuracy, avoid mutual interference, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

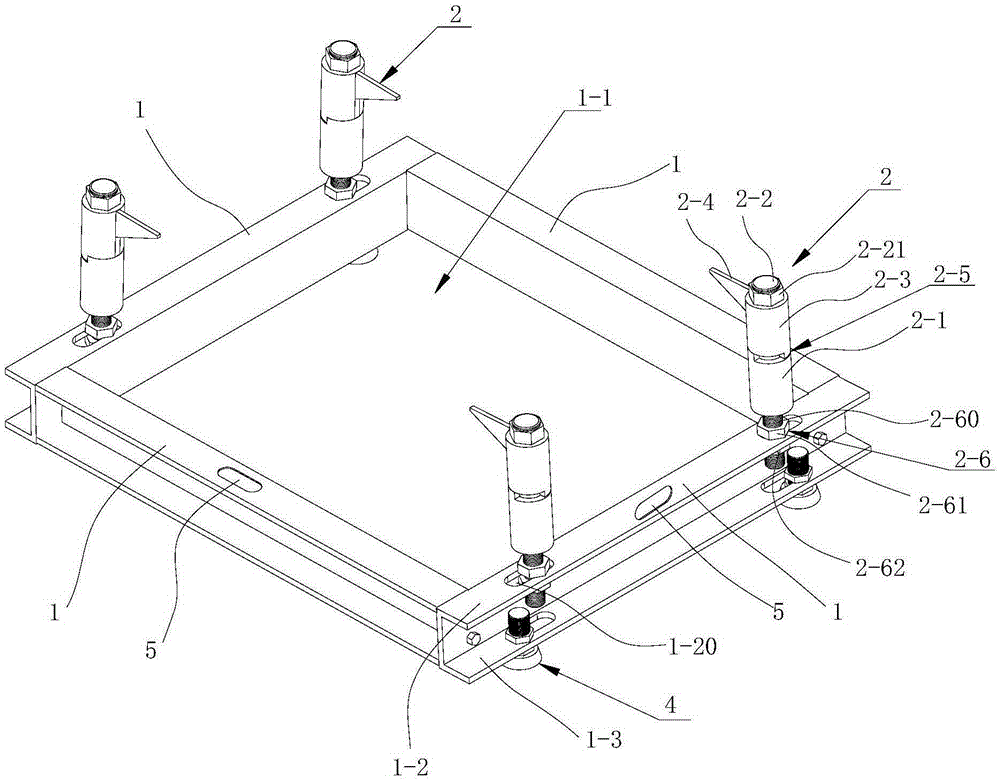

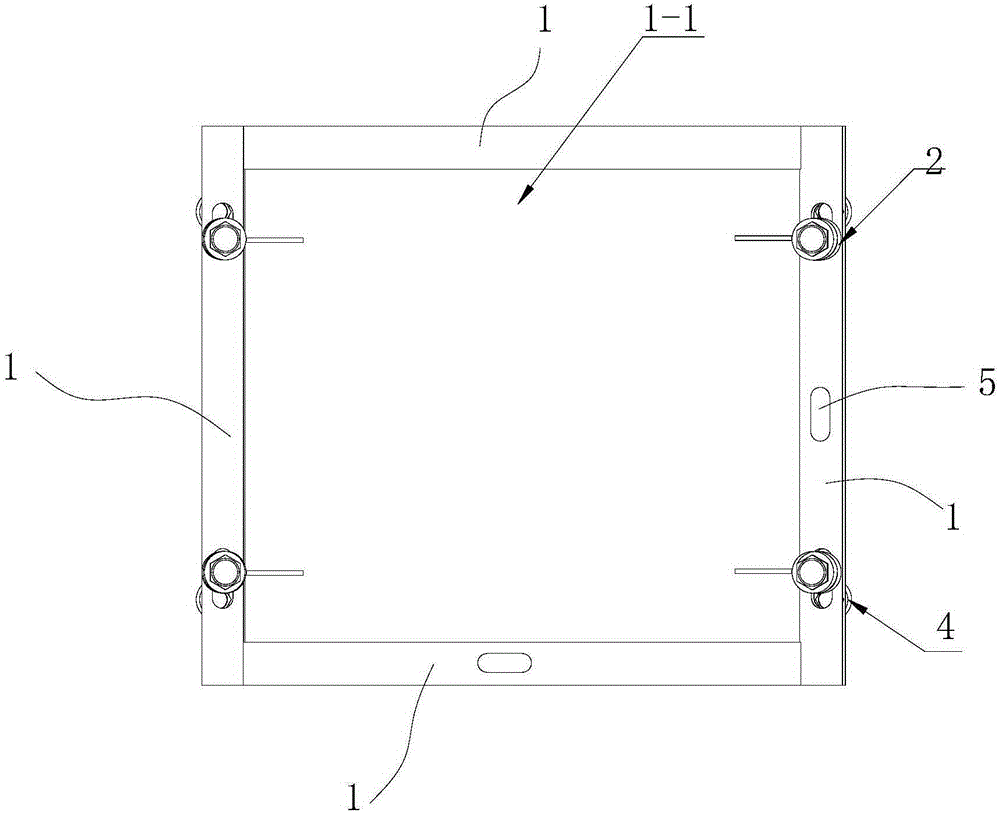

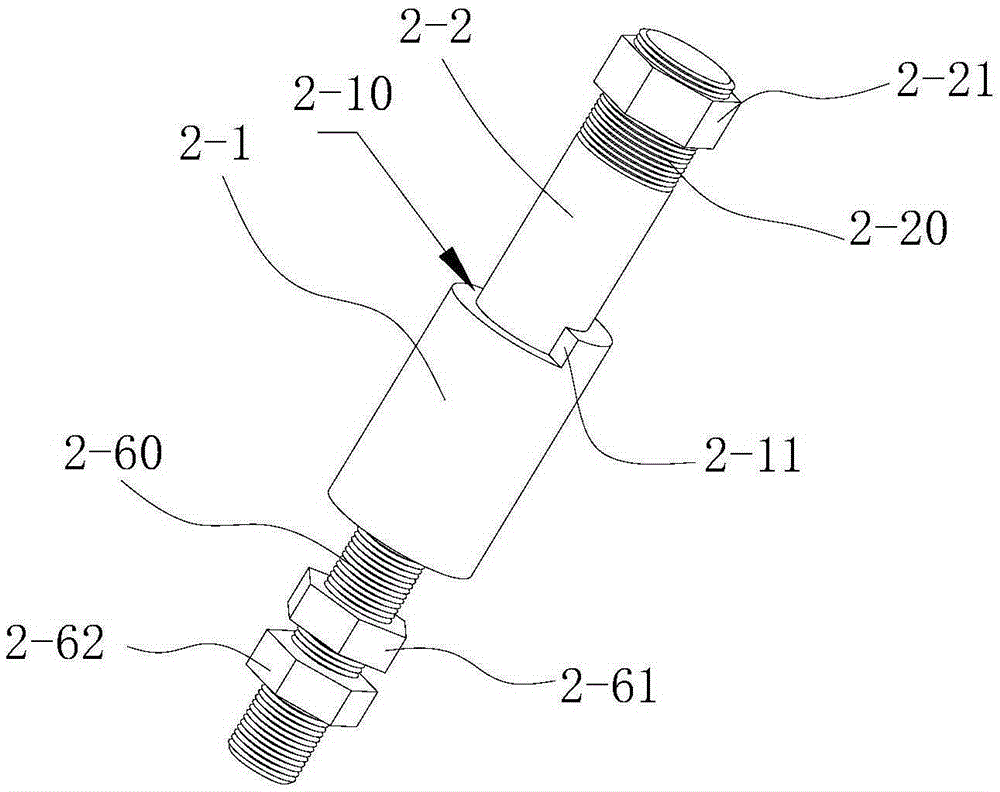

[0022] see Figure 1 to Figure 4 , a large-scale bridge support grouting formwork, the formwork mainly includes four templates 1, the four templates are mutually enclosed and fastened to form a grouting cavity 1-1; the upper and lower surfaces of each of the four templates Both are equipped with an upper mounting plate 1-2 and a lower mounting plate 1-3; the above-mentioned formwork can also be replaced by C-shaped channel steel, and the channel steel should meet the load-bearing requirements; at least one set of relative The upper surface of the formwork is provided with a rotary bridge support mechanism 2, which is adjustable and installed on the upper mounting plate 1-2, and adopts an adjustable structure to meet the adjustment of the dock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com