A spatial geometric positioning method for the wall of a large cooling tower with ribs

A technology of geometric positioning and cooling towers, applied in refrigeration plants, industrial buildings, etc., can solve the problems of poor measurement accuracy, easily affected by human factors, and large measurement errors of cooling towers, so as to improve the construction control accuracy and improve the overall aesthetics and artistic appreciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

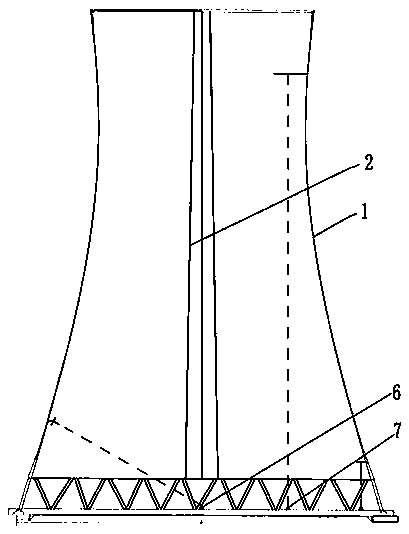

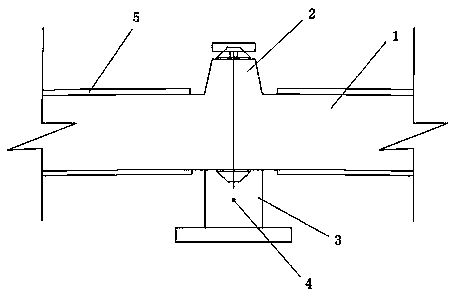

[0045] Such as figure 1 , 2 As shown, each section of the cooling tower wall 1 is formed into a cylindrical shape by assembling and pouring a large formwork 5, and the outer walls of the joints of the two large formworks 5 are vertically arranged with ribs 2 at intervals, and the ribs 2 and the large formwork 5 are poured Integrate into one body; the inner wall of the junction of the two and two large templates 5 is arranged with an inner guide rail 3, and the inner guide rail 3 and the rib 2 are fixed by screws.

[0046] A ribbed large-scale cooling tower wall space geometric positioning method, comprising the following steps:

[0047](1) The center point on the top surface of all inner guide rails 3 is used as the guide rail control point 4; the center point of the bottom of the cooling tower on the ground plane is determined to be the center point 6 of the cooling tower, and all ribs 2 on each section wall The intersection of the outer surface and the vertical centerline ...

Embodiment 2

[0062] The tube wall and rib space geometric positioning control of the first high-level water collection tube wall ribbed cooling tower under construction in China (Shenwan Anqing Power Plant Phase II 2×1000MW unit expansion project #3 cooling tower) is used as an example to specifically illustrate the tube wall and rib space geometric positioning control of the present invention. Wall space geometric positioning control method:

[0063] 1. Space coordinate control of guide rail control point:

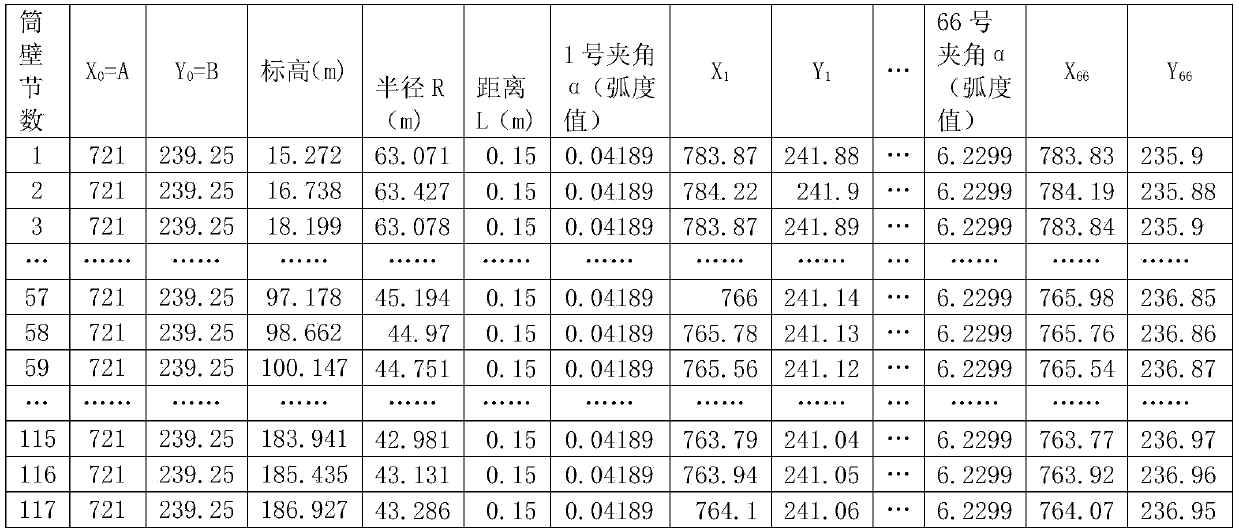

[0064] (1) According to the coordinate system set by the power plant and the given measurement control points around the #3 cooling tower (AD3: A=315.481, B=692.084; AD4: A=315.503, B=951.064; AD5: A=146.966, B=692.479) measure #3 cooling tower central point (coordinate is: X) with total station 0 =721.00,Y 0 =239.25);

[0065] (2) According to the coordinates of the center point of the cooling tower, the outer radius R of the cylinder wall, the elevation H of each section of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com