Scaffold

A scaffolding and pipe fitting technology, applied in the field of scaffolding, can solve the problems of adding a fixed structure, low consistency of connection structure, increased uncertainty, etc., and achieves the effects of saving materials, easy installation of scaffolding, and convenient transportation and placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

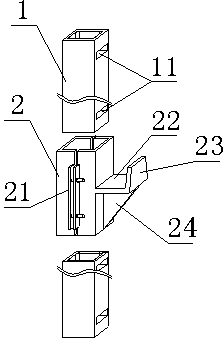

[0010] Such as figure 1 The scaffolding shown is composed of pipe fittings 1 connected by fasteners 2. The pipe fitting 1 is a seamless square pipe structure, and both ends are provided with through holes 11, and the through holes 11 are arranged in the radial direction of the pipe fitting 1.

[0011] The fastener 2 is a hinge structure connected by double bolts 21. A base 22 is fixed on the side of the hinge. A protrusion 23 extends from the base 22 along the axis of the hinge. The protrusion 23 is connected to the pipe 1 The size of the through hole 11 matches that of the through hole 11, and the protrusion 23 can be inserted into the through hole 11.

[0012] When installing scaffolding, you can figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com