Multi-coupling efficient grinding machine for manganese-zinc material magnetic core production

A grinding machine and magnetic core technology, which is applied in the field of multi-coupling high-efficiency grinding machines for the production of manganese-zinc material magnetic cores, can solve problems such as obstacles to use, a large amount of manpower, and burrs on the corners, so as to increase the grinding position and improve the grinding effect , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

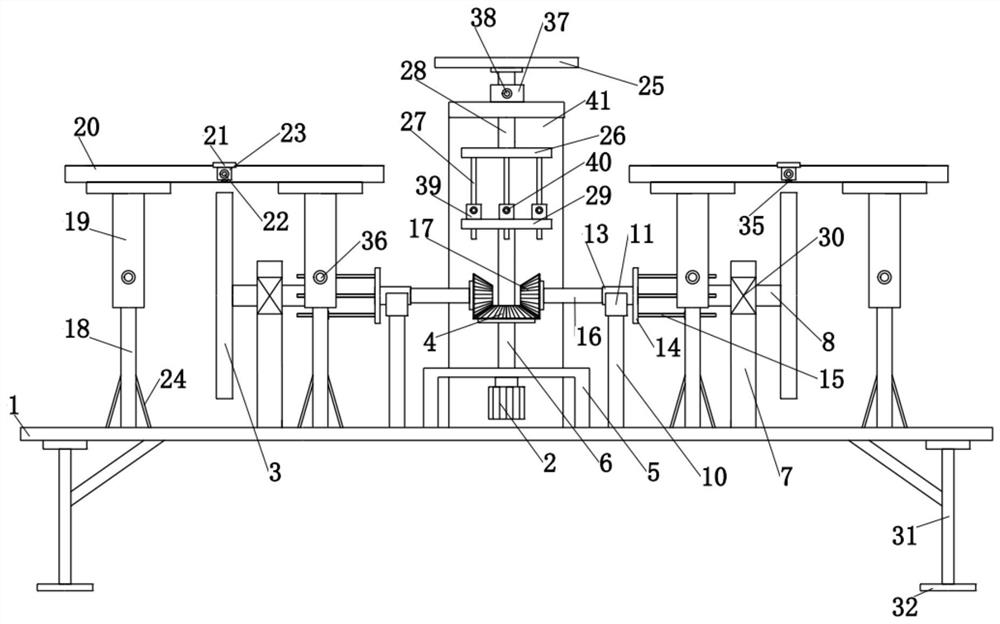

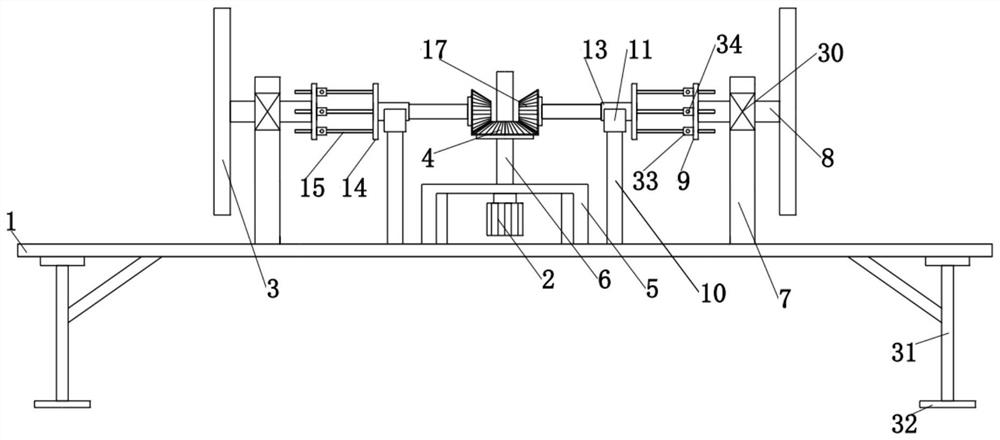

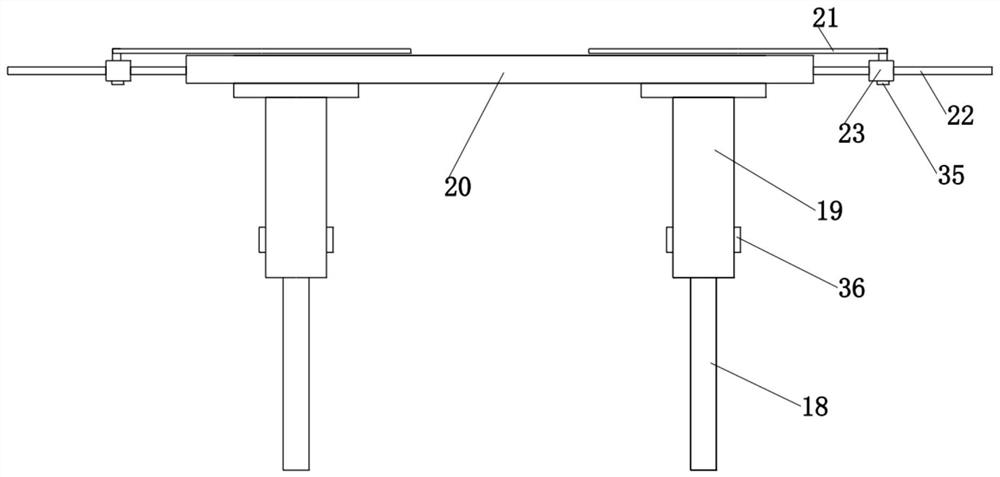

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, a multi-coupling high-efficiency grinding machine for the production of manganese-zinc material magnetic cores includes an operating table 1, which is provided with a grinding structure and a supporting load-bearing structure; the grinding structure includes: a servo motor 2, a first grinding wheel 3 and The first tilting gear 4; the console 1 is fixed with a support frame 5, the upper wall of the support frame 5 is provided with a first circular through hole, the servo motor 2 is inserted into the first circular through hole, and the drive end of the servo motor 2 The first connecting rod 6 is installed, the first tilting gear 4 is placed on the first connecting rod 6, the upper wall surface of the console 1 and the left and right sides of the support frame 5 are fixed with the first bracket 7, and the first bracket 7 is provided with The second circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com