Coil terminal and contactor with coil terminal

A technology of coil wiring and contactor, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as inability to design and assemble foolproof structures, and achieve the effect of reducing the wiring pressure arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

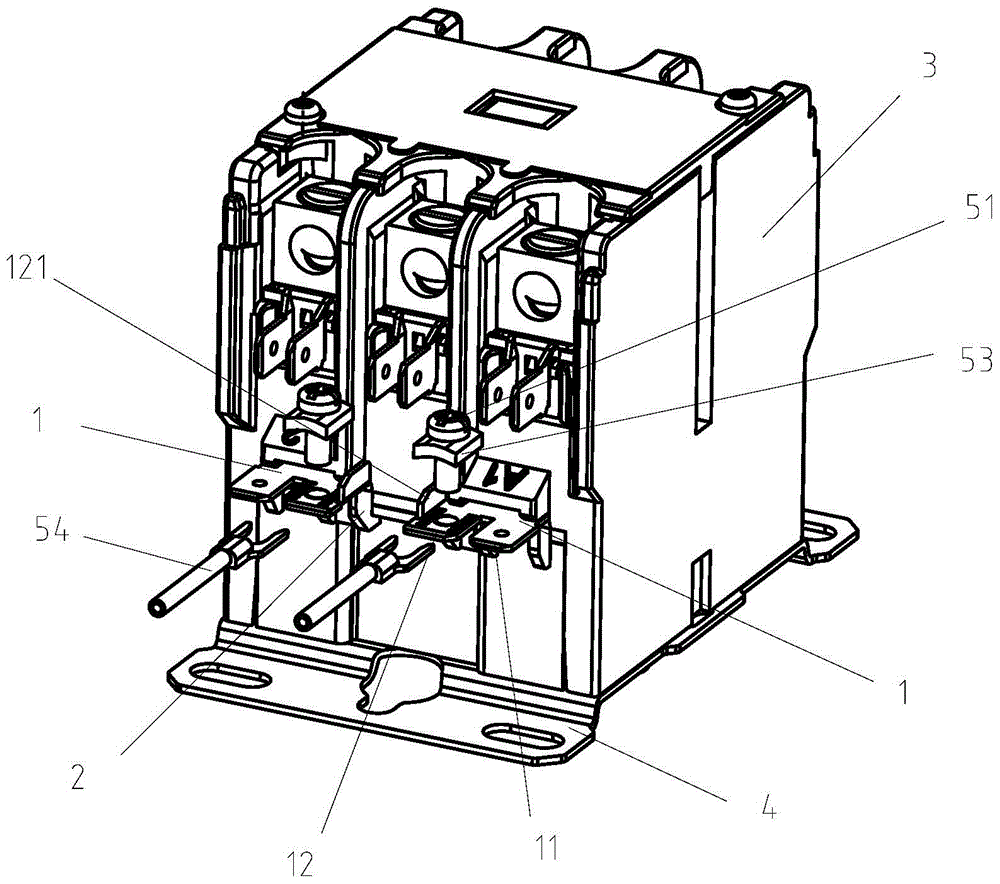

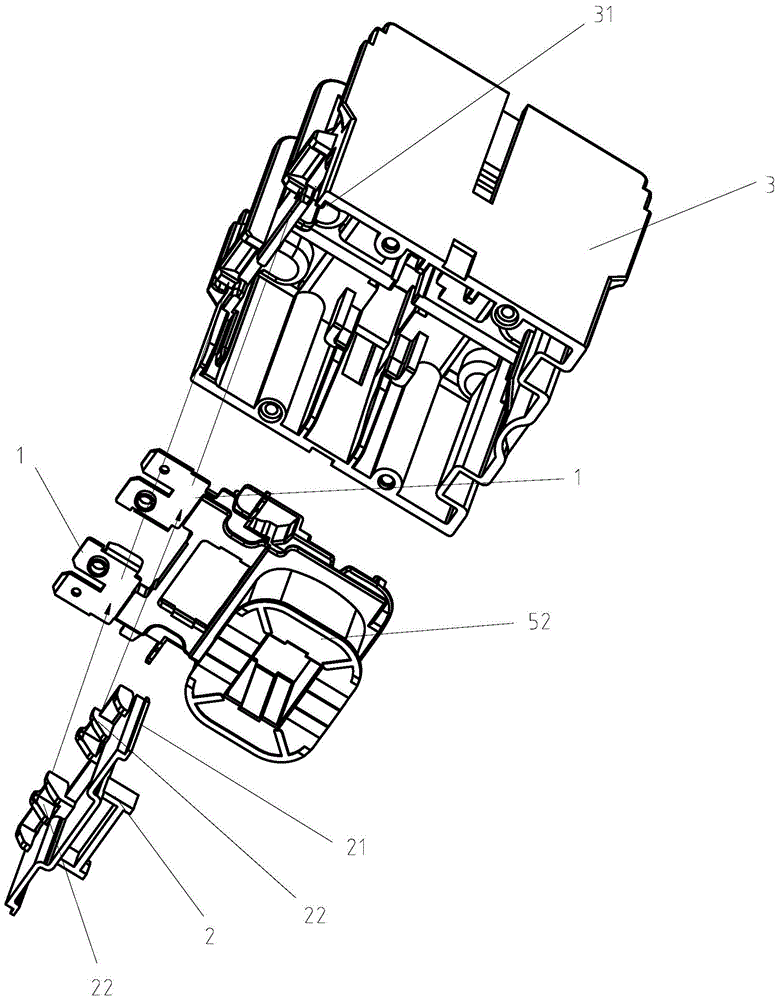

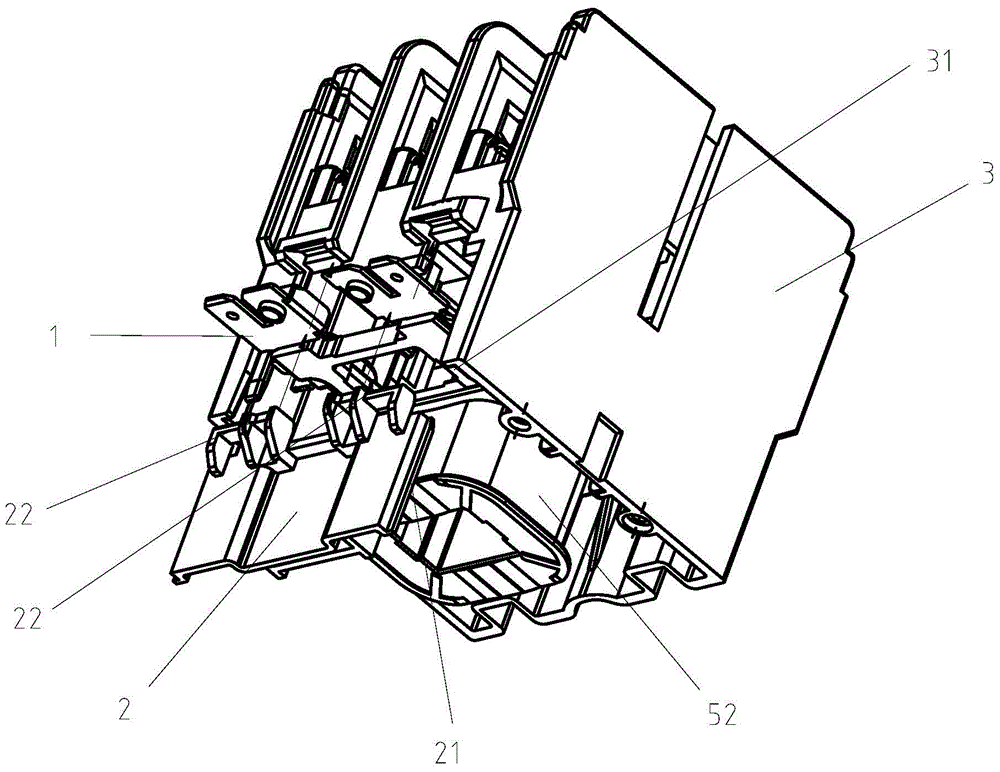

[0039] see Figure 1 to Figure 8As shown, a coil terminal of the present invention, the coil terminal 1 has two lugs, the rear parts of the two lugs are connected, at least one of the two lugs is a screw connection part, and one of the lugs 11 It is used for quick-connect socket wiring, and the other lug 12 is used for screw 51 wiring. The outer edge of the lug 12 of the screw wiring part relative to the other lug is provided with a bending part 121 with a certain height upward. .

[0040] A contactor with coil terminals of the present invention comprises two coil terminals 1, a clamp 2, a body 3 and a base 4; the two coil terminals 1 have two lugs respectively, One of the lugs 11 is used for quick-connect socket wiring, and the other lug 12 is used for screw 51 wiring, which belongs to the wiring method of 1 screw connection + 1 quick-connect socket wiring; two lugs (that is, lug 11 , lugs 12) are connected in one body and extend backwards to form a mounting portion 13, the...

Embodiment 2

[0049] see Figure 9 to Figure 11 As shown, a contactor with a coil terminal of the present invention is different from Embodiment 1 in that the coil terminal 6 is different, but the card board is still the same, and the two connections of the coil terminal 6 Sheets 61 are all used for quick-connect socket wiring, and belong to two quick-connect socket wiring schemes. Since the quick-connect socket 62 is used, the coil terminal 6 does not need to be provided with a bending portion. After the card board 2 is matched with the coil terminal 6, the supporting part 22 of the card board 2 is only supported at the junction of the two lugs 61, and a space 63 for the quick-connect socket 62 is formed under the lugs 61 .

Embodiment 3

[0051] see Figure 12 to Figure 13 As shown, a contactor with a coil terminal of the present invention is different from Embodiment 1 in that the coil terminal 7 is different, but the card board is still the same, and the two connections of the coil terminal 7 Sheets 71 are used for screw connection and belong to two screw connection schemes. Since all screws 72 and matching tile pads 53 are used, the coil terminal 7 must be provided with two bending parts 711. The supporting portion 22 of the card board 2 is supported at the junction of the two lugs 71 .

[0052] It can be seen from the above three embodiments that whether it is 2 quick-connect socket wiring, or 2 screw wiring, or 1 screw wiring + 1 quick-connect socket wiring (position exchange), the same method is adopted. Card board 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com