Composite structure duplex winding maglev switched reluctance motor

A technology of switched reluctance motors and reluctance motors, applied in the direction of magnetic circuit shape/style/structure, synchronous motors for single-phase current, shape/style/structure of winding conductors, etc., to achieve high-speed adaptability, current Good real-time control effect and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

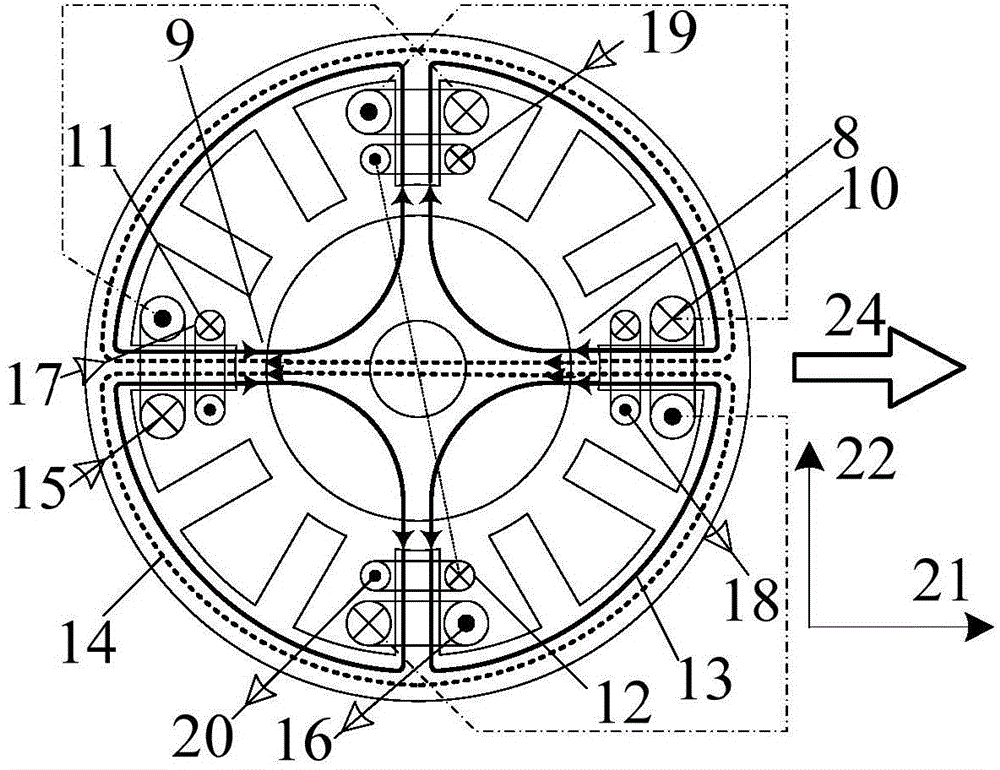

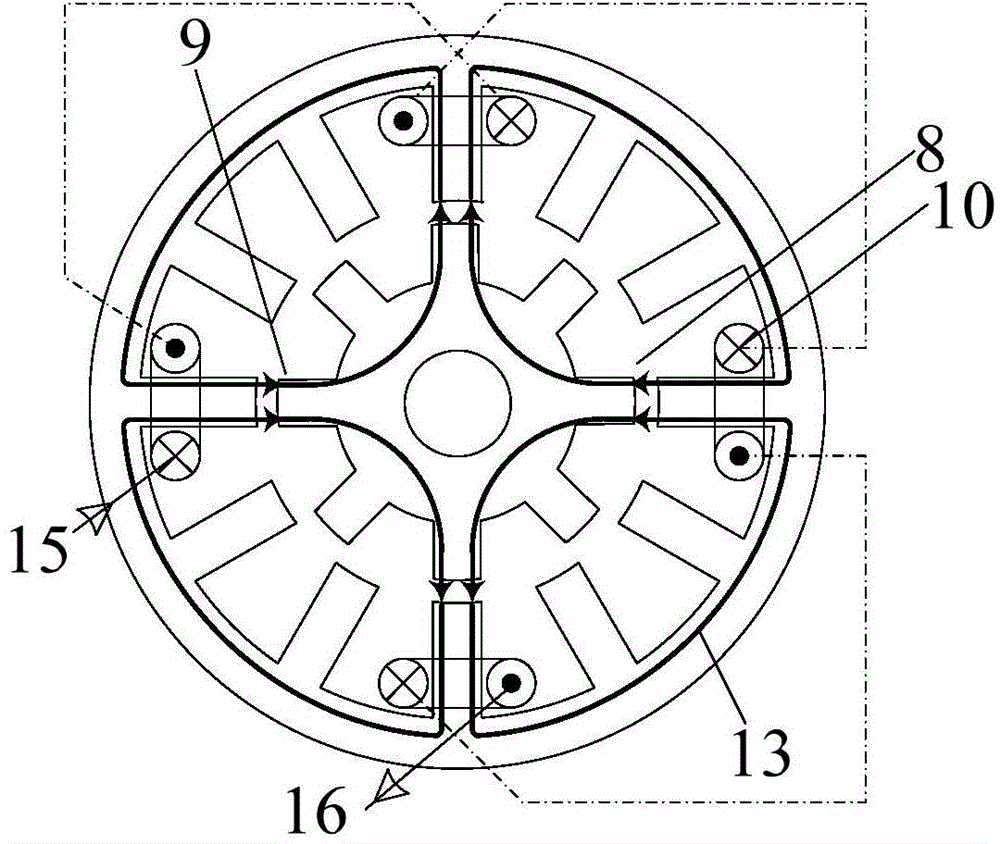

[0027] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

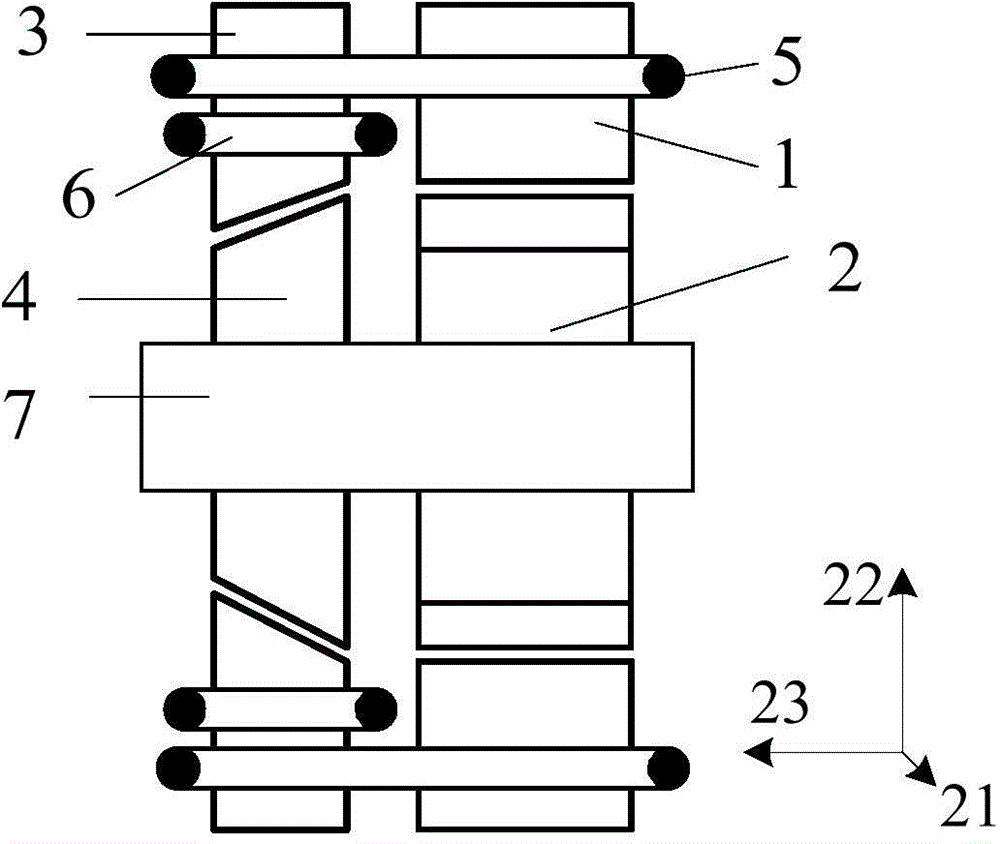

[0028] Such as figure 1 Shown, the structure schematic diagram of a kind of composite structure double-winding magnetic levitation switched reluctance motor of the present invention, wherein, 1 is reluctance motor stator, 2 is reluctance motor rotor, 3 is conical magnetic bearing stator, 4 is conical magnetic bearing Bearing rotor, 5 is a torque winding, 6 is a suspension force winding, and 7 is a rotating shaft.

[0029] The composite structure double-winding magnetic levitation switched reluctance motor of the present invention comprises a motor stator, a motor rotor, a motor winding and a rotating shaft;

[0030] The motor stator is composed of a reluctance motor stator and a conical magnetic bearing stator, the reluctance motor stator is a salient pole structure, the conical magnetic bearing stator is a conical salient pole structure, and the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com