High-efficiency dust removal method for pretreatment workshop

A pretreatment, workshop technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as poor dust removal effect, and achieve the effect of simple and convenient use and broad market development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

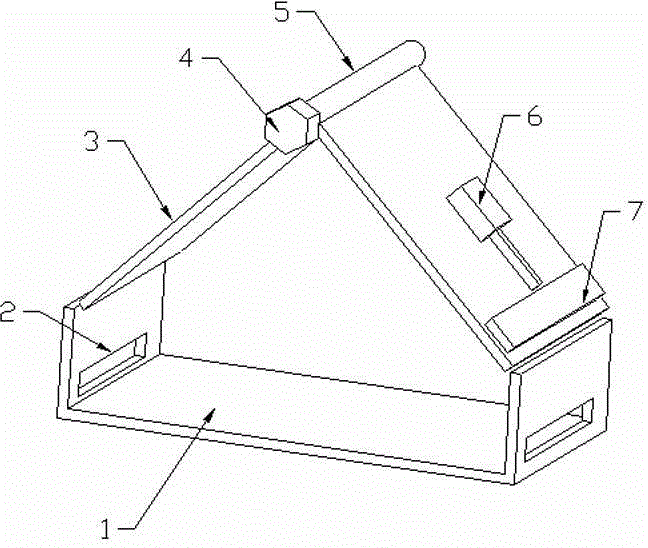

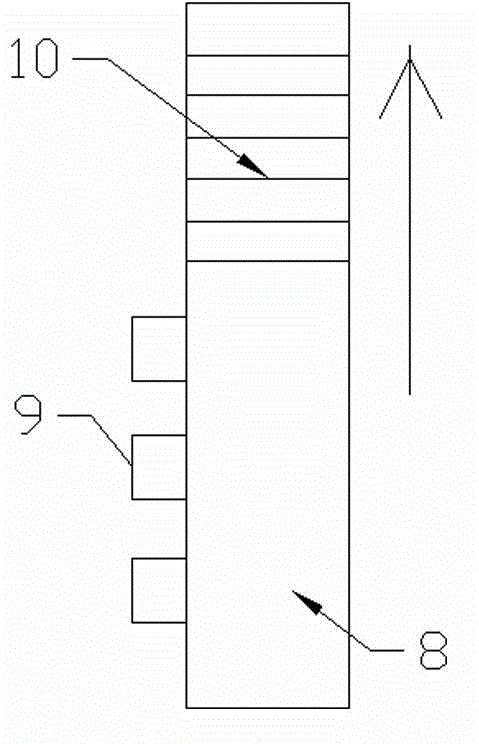

[0019] The efficient dedusting method of the pretreatment workshop, including workshop 1, air hole 2, roof 3, motor 4, rotating shaft 5, cylinder 6, slide plate 7, settling pipeline 8, atomizer 9 and water wall 10, is characterized in that it includes the following steps:

[0020] A Install the triangular roof 3 above the workshop 1;

[0021] B When the wind comes from the left side, the motor 4 drives the rotating shaft 5 to make the roof 3 rotate clockwise, and the left side exposes a big opening, and the cylinder 6 on the right side drives the slide plate 7 to move down, blocking the gap between the roof 3 and the workshop 1;

[0022] C When a large amount of wind is blown in from the left side, the dust in the workshop 1 will quickly go out from the air hole 2 below, and the air hole 2 is connected to the settling pipe 8, realizing the global ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com