Clamp for door processing

A door and fixture technology, applied in the direction of spraying device, etc., can solve the problems of inability to adjust the position of the door, uneven painting of the door, etc., and achieve the effect of avoiding uneven painting and avoiding uneven painting of the door.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

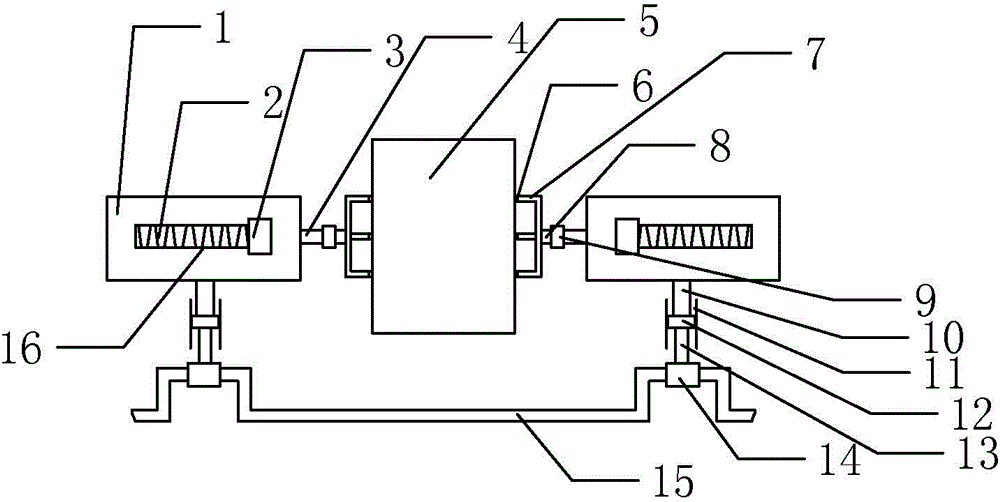

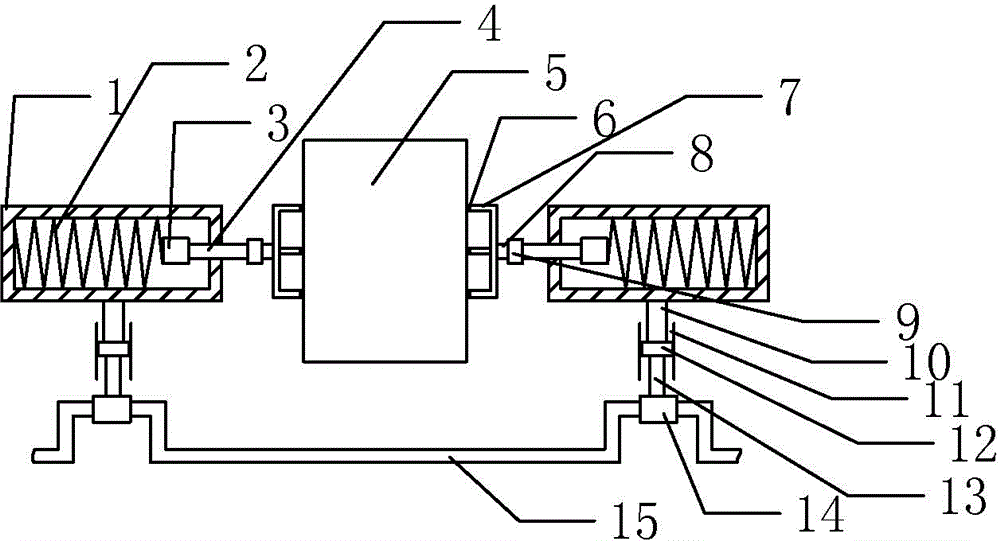

[0014] Sliding box 1, compression spring 2, pressure block 3, support rod 4, door 5, elastic pad 6, chuck 7, connecting rod 8, sleeve 9, support column 10, slideway 11, slider 12, hinge rod 13, drum 14, crankshaft 15, chute 16.

[0015] Such as figure 1 , 2 As shown, the fixture for processing the door 5 of the present invention includes a crankshaft 15 and two oppositely arranged clamping bodies. The crankshaft 15 is wave-shaped, and the crankshaft 15 includes a wave trough and two peaks, and the heights of the two wave peaks are equal; the clamping body includes Slideway 11 and cuboid sliding box 1, slideway 11 is provided with slide block 12, and slide block 12 can move up and down in slideway 11 under the effect of external force, and the lower end of slide block 12 is hinged with hinge rod 13, The lower end of the articulated rod 13 is fixedly connected with a drum 14, and the drums 14 of the two clamp bodies are respectively sleeved on the two crests of the crankshaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com