Rolling device and rolling method of compound copper and aluminum busbar

A copper-aluminum composite row and material guiding device technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of many processing and rolling passes, reciprocating processing, increasing production costs, etc. The effect of reducing processing times, improving processing efficiency, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

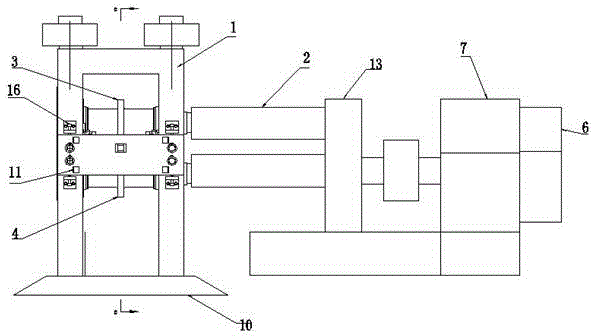

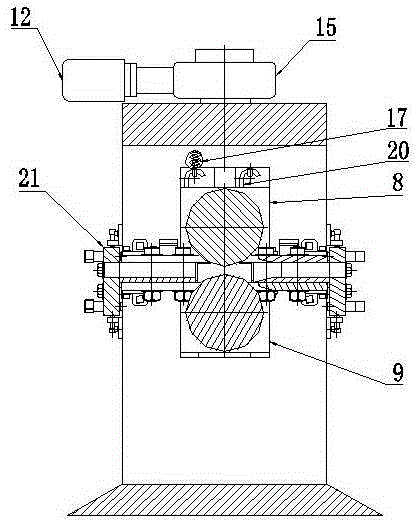

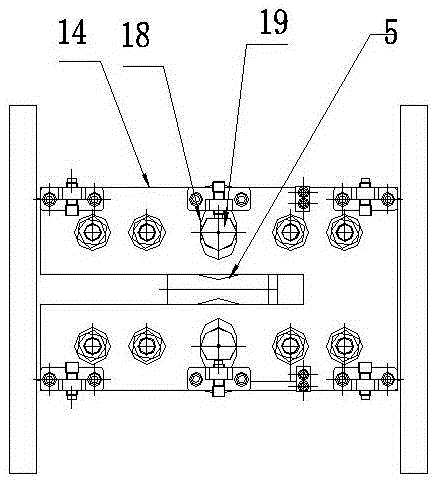

[0022] For better understanding and implementation, the present invention will be described in detail below in conjunction with the accompanying drawings: a rolling device for a copper-aluminum composite row, including a main motor 6, the main motor 6 is connected to a reducer 7, and the reducer 7 is connected to a transmission system 13 connected, the coupling 2 is connected with the two upper flat rolls 3 and the lower flat roll 4 on the main frame 1, the main frame 1 is fixed on the base 10, and the main frame 1 is fixed with an upper bearing seat 8 and a lower bearing Seat 9, the upper bearing seat 8 is connected with the worm gear 15, the worm gear 15 is connected with the pressing motor 12, the upper flat roll 3 is arranged in the upper bearing housing 8, the lifting rod 20 is arranged on the upper bearing housing 8, and the lifting rod 20 is The hoisting spring 17 is installed, the lower flat roller 4 is arranged on the lower bearing seat 9, and the adjustment bending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com