Comber cleaner, apparatus making same, and integral insert applied to apparatus

A cleaner and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problems of easy brown hair loss, damage to equipment, and short service time, so as to improve product quality, prolong service life, The effect of high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

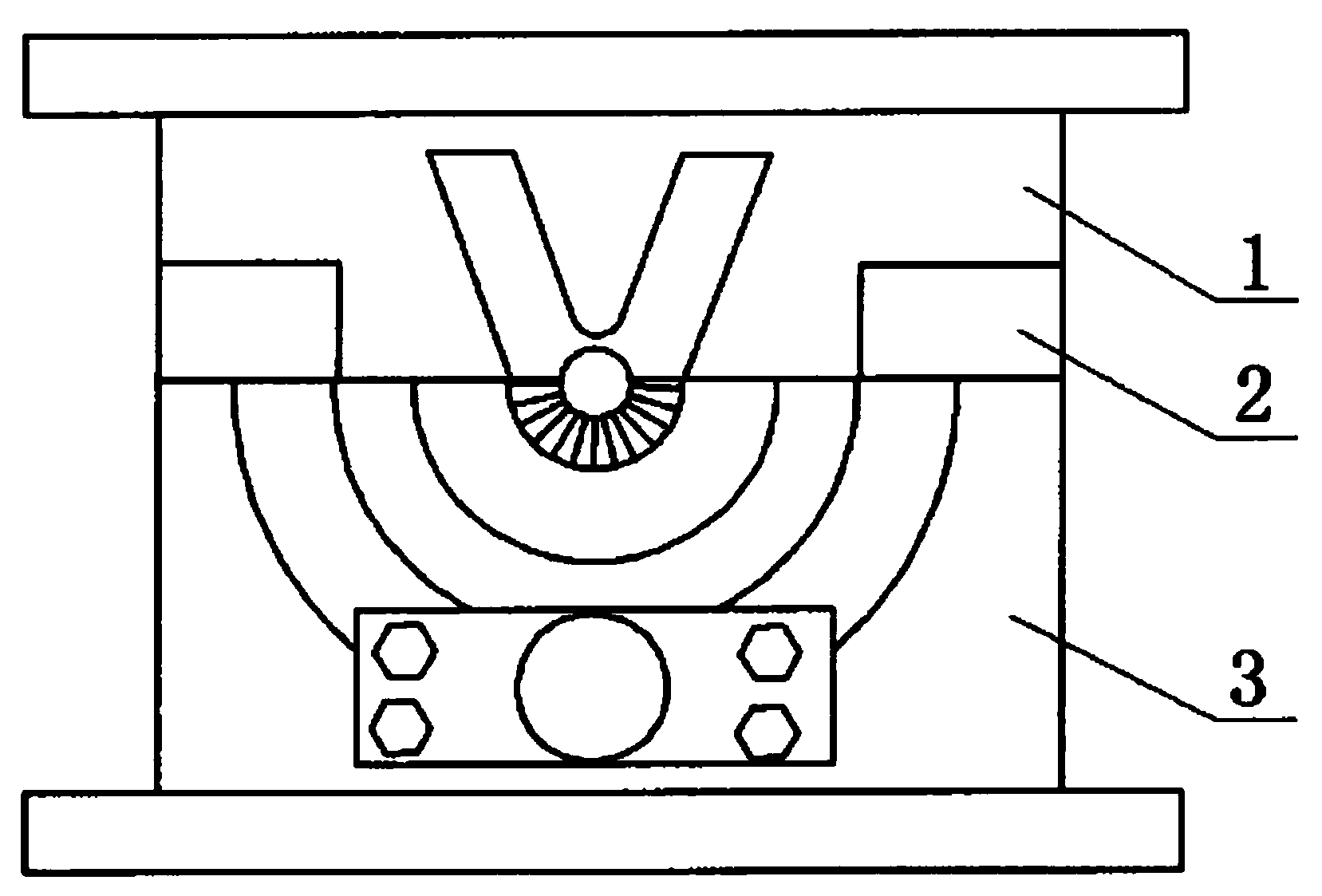

[0033] Pull the 3 parts of the movable mold structure of the mold outward (open the mold), and the static mold of the mold is the inner core of the cleaner injection part, and separate the inner core 1 of the cleaner injection part and the mold pusher plate from the cleaner outer shape slider 2 To the set position, it is just enough to put the insert of the plastic tube nailed into the brown wool.

[0034] Then mold the movable mold structure 3 to the mold pushing plate, the cleaner profile slide block 2 and the cleaner injection part inner core 1 (closed mold) and inject after injection molding. After the injection molding is completed, the mold movable mold structure 3 is pulled outwards (opened) mold). The product (cleaner) is taken out from between the inner core 1 of the injection part of the cleaner and the ejector plate of the mold and the slider 2 of the cleaner shape. Take the plastic tube out from the mold ejector plate and cleaner profile slider 2. The brown wool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com