Universal loss prevention oil tank cover

A general-purpose engine oil and anti-lost technology, which is applied to the cover with auxiliary devices, the arrangement combined with the fuel supply of the internal combustion engine, and the sealing parts with auxiliary devices, etc., can solve potential safety hazards, forget the position of the fuel tank cap, and waste time and other issues to achieve the effect of improving security, simple structure, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

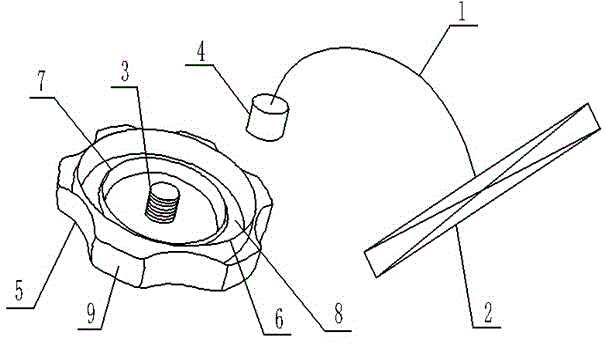

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the anti-lost universal oil tank cap in this specific embodiment includes a fuel tank cap that is threadedly matched with the fuel tank port. The fuel tank cap is provided with an anti-dropping device, and the anti-dropping device includes an anti-dropping chain rope 1 and a bar clip. Head 2, the inner end surface of the fuel tank cover is provided with a stud 3, and one end of the anti-drop chain rope 1 is provided with a nut 4 threaded with the stud 3, and the anti-drop chain rope 1 The other end is connected with the center of the bar-shaped chuck 2, and the length of the bar-shaped chuck 2 is greater than the inner diameter of the fuel tank port.

[0014] In this specific embodiment, the fuel tank cover also includes an outer cover 5 and an inner cover 6 threadedly fitted with the fuel tank port, and the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com