Overturning device for soft bag production line and soft bag production line

A technology of turning device and production line, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of not preventing the turning of the fixture, damage to the fixture, rust, etc., so as to improve the production efficiency of bag making, reduce equipment failure, avoid damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

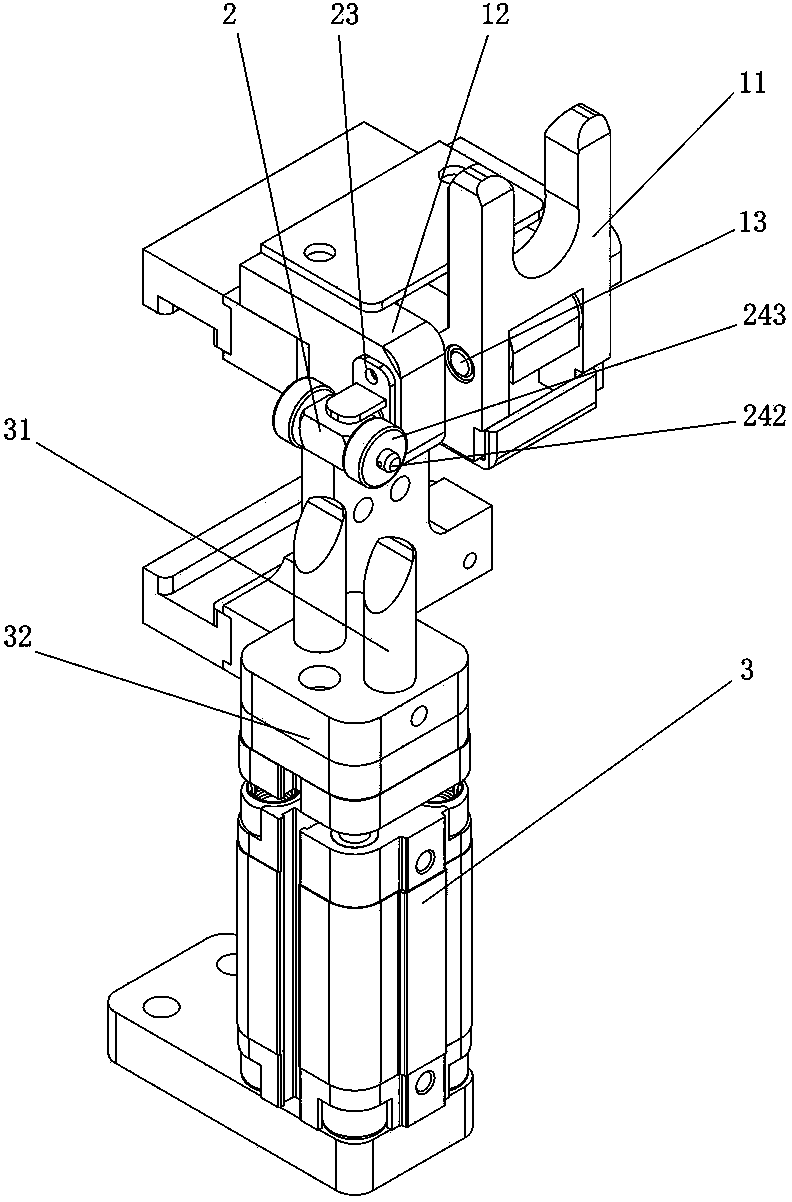

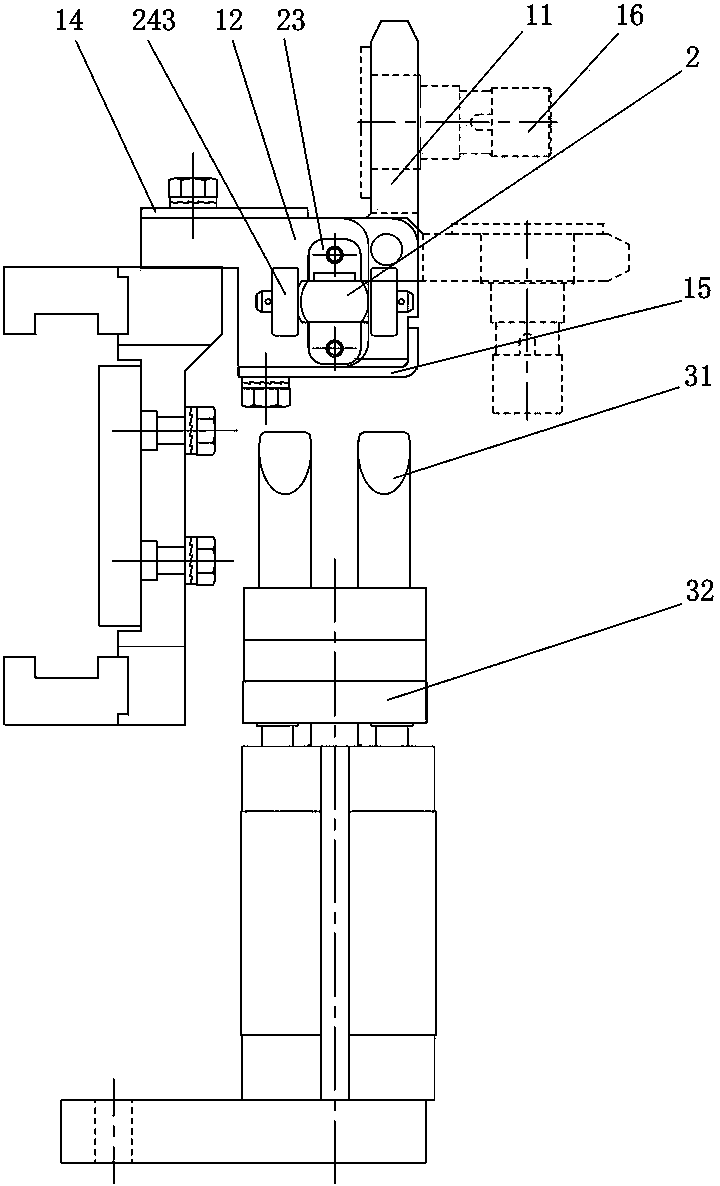

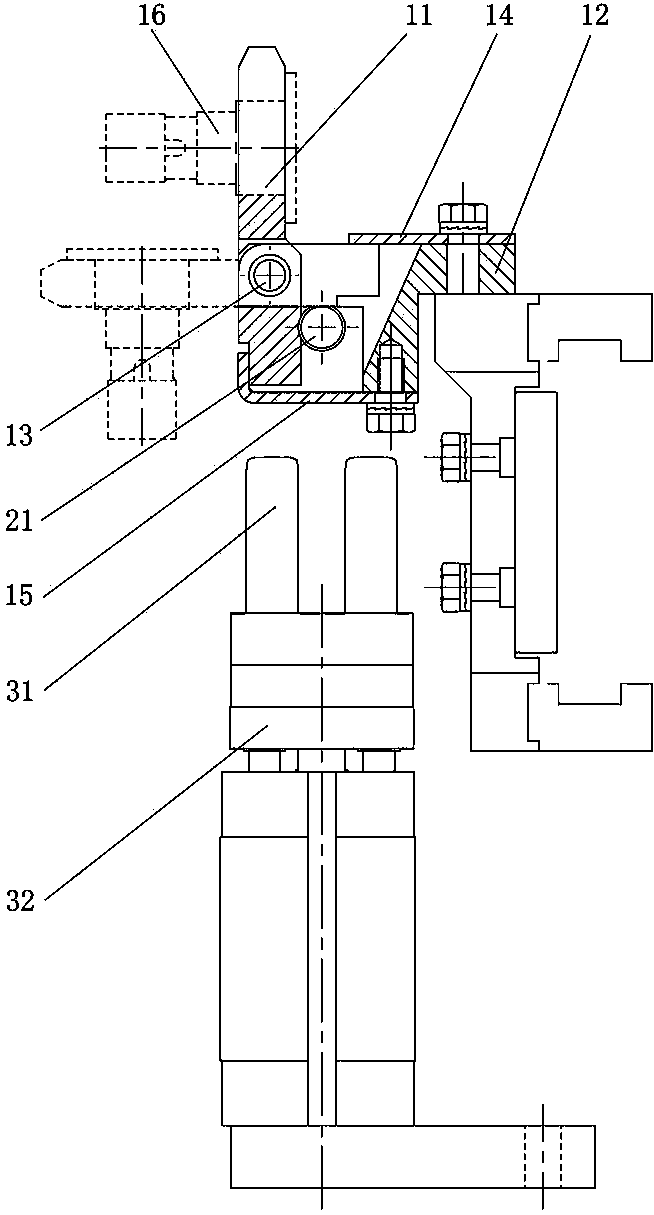

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] Figure 1 to Figure 9 The first embodiment of the turning device used in the soft bag production line of the present invention is shown, the turning device used in the soft bag production line includes a soft bag interface clip 11, an interface base 12 and a turning shaft 13, the soft bag interface clip 11 Installed on the interface base 12, and can rotate around the turning shaft 13 so that the soft bag interface folder 11 can be switched between the horizontal position and the vertical position. The turning device also includes a limit locking device 2. In the horizontal position or the vertical position, the limit locking device 2 prevents the soft bag interface clip 11 from turning over, and the soft bag interface clip 11 can be turned vertically and horizontally relative to the interface base 12, so as to facilitate bag ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com