A kind of device and method for producing ammonium sulfate

A technology of ammonium sulfate and crystallization reactor, which is applied in the direction of ammonium sulfate, etc., can solve the problems of high investment, many equipment, and failure to use, and achieve the effect of reducing investment and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

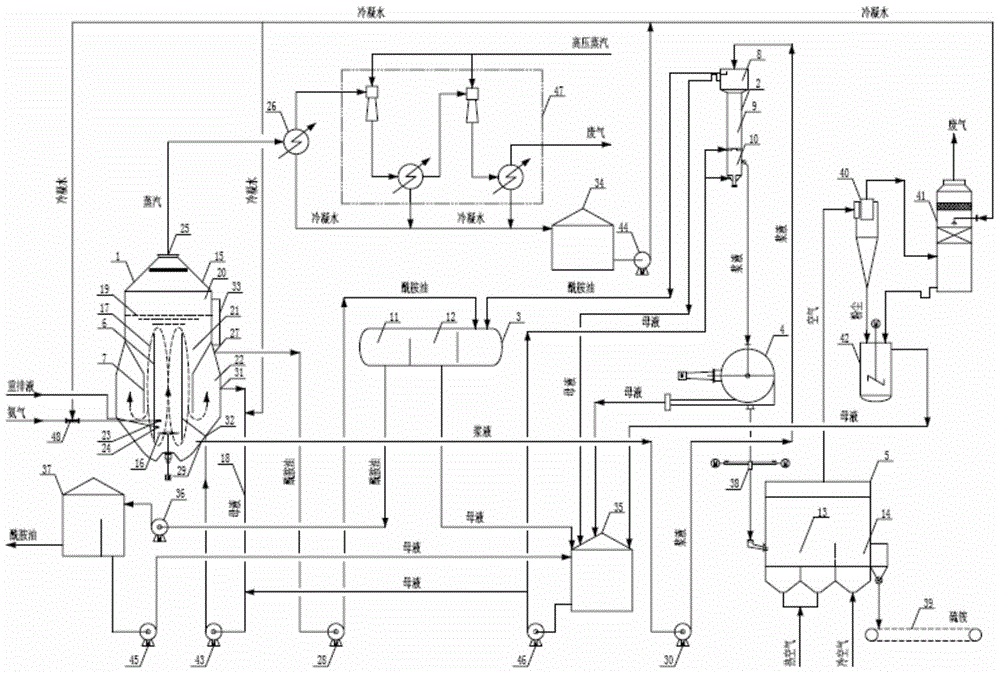

[0041] The method for producing ammonium sulfate of the present invention, its preferred embodiment is:

[0042] It includes the following four processes: neutralization and crystallization process, amide oil decanting and storage and mother liquor circulation process, slurry thickening and centrifugal separation process, ammonium sulfate drying and washing process.

[0043] The neutralization and crystallization process flow includes the following steps: After the ammonia gas and the condensed water from the condensate collection tank 34 are fully mixed through the static mixer 48, the rearrangement liquid from the cyclohexanone oximation unit passes through the neutralization crystallization reactor 1 respectively The 4 nozzles on the inner annular distributor enter the draft tube 6 of the neutralization crystallization reactor 1 . In the guide tube 6, ammonia and sulfuric acid undergo a neutralization reaction to generate ammonium sulfate and produce crystal nuclei. With th...

specific Embodiment

[0054] Such as figure 1 As shown, it mainly includes a neutralization crystallization reactor 1, a thickener 2, a decanter 3, a centrifuge 4, and a fluidized bed dryer 5, which are connected by pipelines. The device of the present invention can react the rearrangement liquid from the upstream cyclohexanone oximation device with ammonia water to generate ammonium sulfate particles, which can be separated and dried to obtain ammonium sulfate products, and at the same time, the amide oil is separated and sent to the downstream caprolactam refining device for refining The caprolactam product is obtained.

[0055] During normal operation, the material in the neutralization crystallization reactor 1 maintains a pH value of 3-4, and the pressure is controlled at 7-17kPa (absolute pressure) by the vacuum system 47. The position is maintained at 45-55% by adding saturated mother liquor and condensed water, and the materials are fully mixed by the continuously running agitator 16 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com