Buckle plate type medium and low speed maglev transportation system track telescopic adjustment structure

A transportation system, telescopic adjustment technology, applied in the field of rail transportation system, achieves the effect of simple structure, reducing interaction force and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

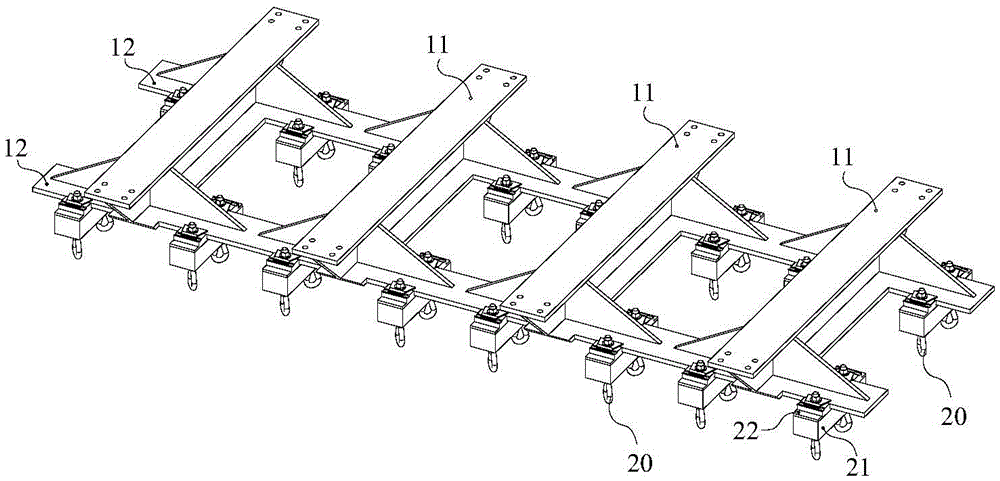

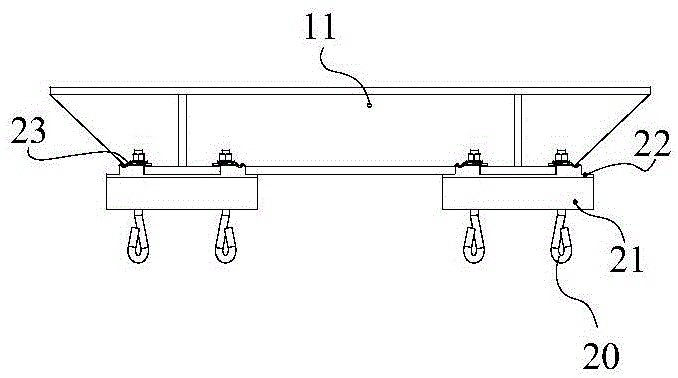

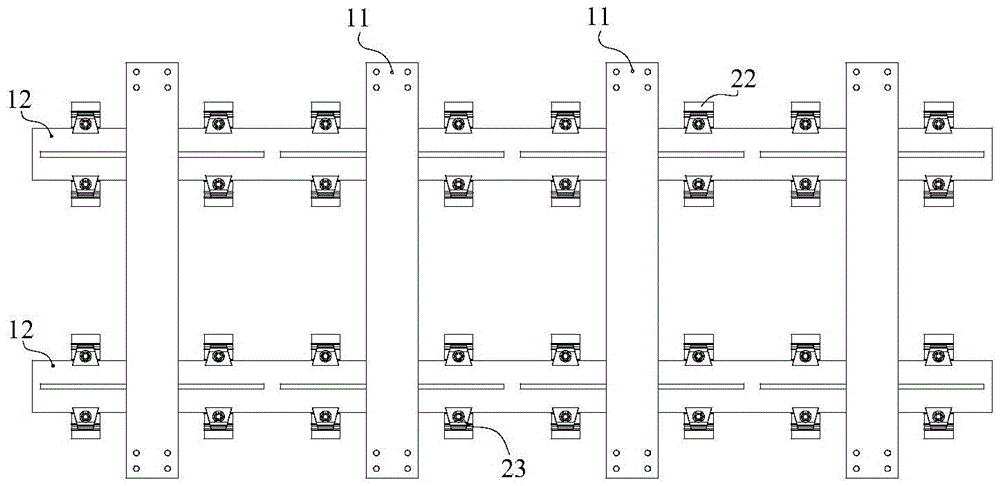

[0020] Reference Figure 7 , figure 1 , figure 2 with image 3 , The gusset-type mid-low-speed maglev transportation system track expansion adjustment structure of the present invention includes: a rib-type rail row, the main body of which is composed of a sleeper unit 11 arranged at intervals in the longitudinal direction and two longitudinal connecting plates 12 arranged at intervals which are fixedly connected as a whole. , Each sleeper unit 11 and the longitudinal connecting plate 12 are welded with ribs 13; the rail supports 21 are arranged in two rows on the bridge girder at a lateral interval; the backing plates 22 are arranged on the top surface of each support 21 and are connected longitudinally Between the bottom surfaces of the plates 12, the top surfaces have laterally spaced gusset plate fixing protrusions 22a; the anchor bolt assembly 20 and the gusset p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com