display device

A technology for display devices and display screens, applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of time-consuming and labor-intensive assembly and disassembly processes, increase the assembly cost of lifting mechanisms, reduce the convenience of lifting mechanisms, etc., and achieve simplification The effect of the assembly and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

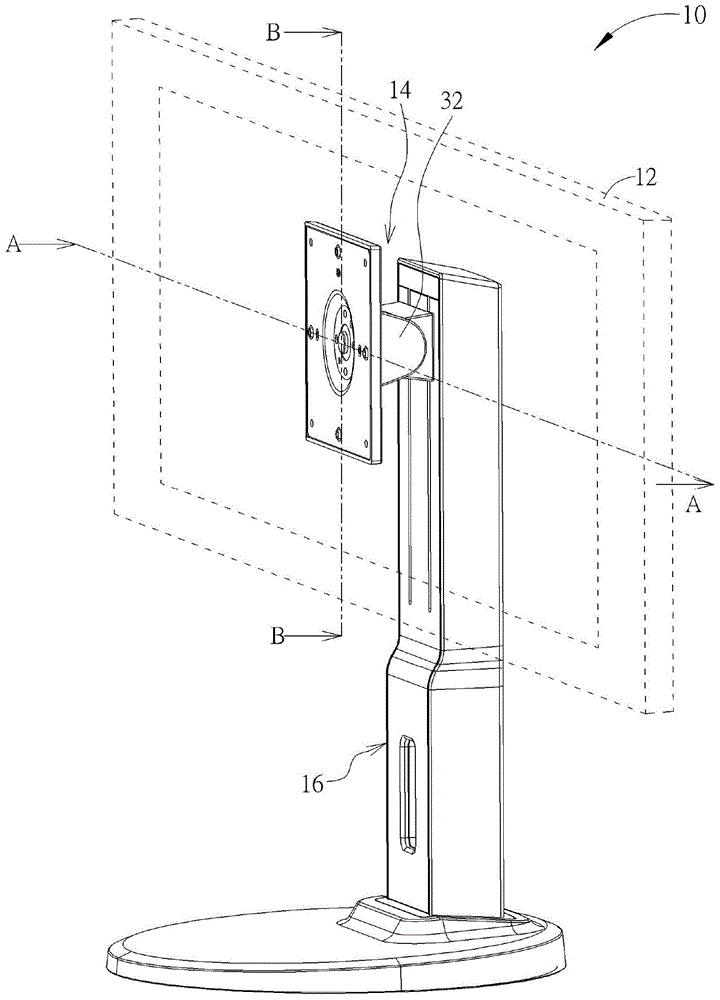

[0028] see figure 1 , which is a three-dimensional schematic diagram of a display device 10 proposed according to an embodiment of the present invention, as shown in figure 1 As shown, the display device 10 includes a display screen 12 and a lifting mechanism 14, wherein in order to clearly show the mechanism design of the lifting mechanism 14, the display screen 12 is in the figure 1 Indicated by a dotted line, the display screen 12 can be a common display, such as a liquid crystal display screen or an All-in-One desktop computer. The lifting mechanism 14 can be used to adjust the height of the display screen 12 , and the mechanism design of the lifting mechanism 14 will be described in detail below.

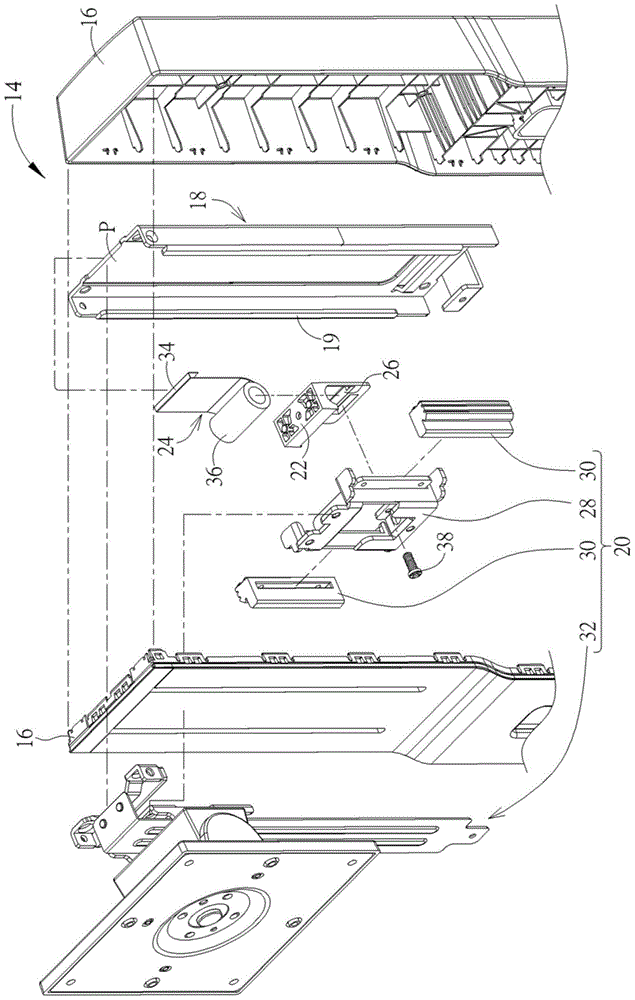

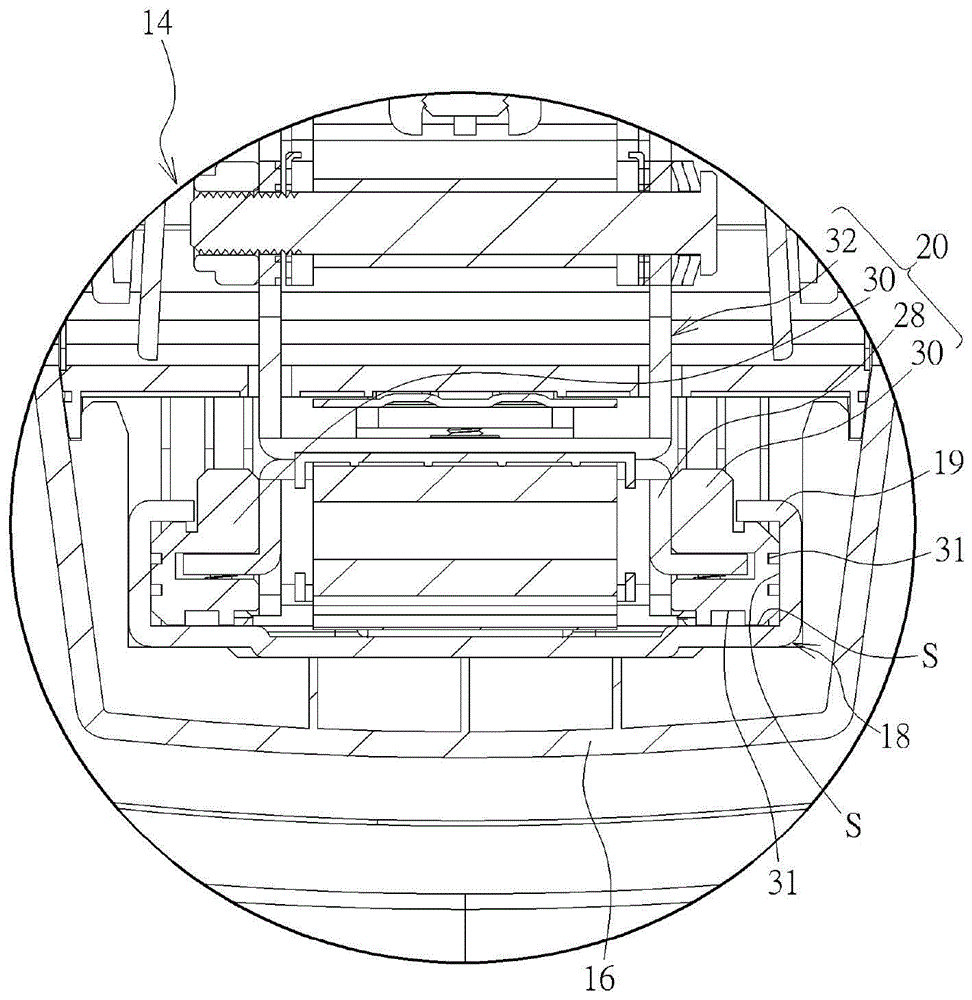

[0029] Please also see figure 1 , figure 2 as well as image 3 , figure 2 for figure 1 The explosion schematic diagram of the lifting mechanism 14, image 3 for figure 1 A partial cross-sectional schematic diagram of the display device 10 along the section line A-A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com