Barrel-shaped workpiece taking-out jig

A workpiece and jig technology, which is applied in the field of barrel-shaped workpiece removal jigs, can solve the problems of heavy jig weight, high failure rate, and many fixing parts, and achieve the goal of reducing jig cost, maintenance difficulty, and failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

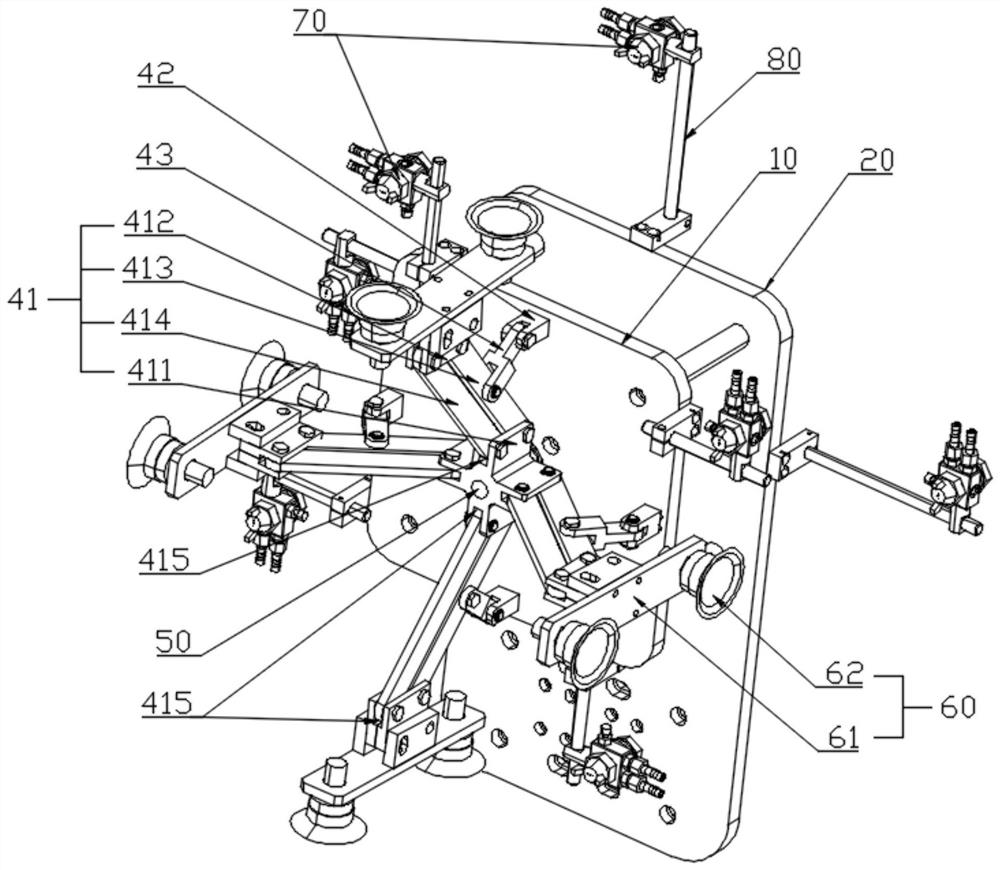

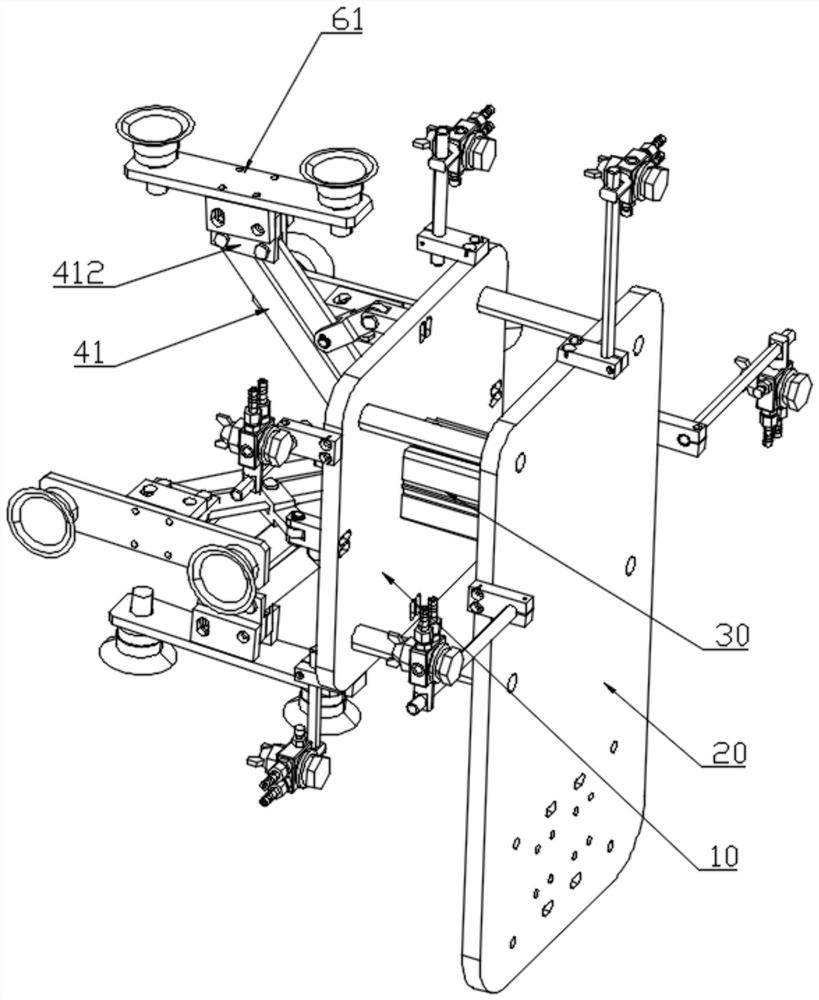

[0029] see Figure 1 to Figure 4 , a barrel-shaped workpiece removal jig of the present embodiment, including a jig plate 10, a fixed mounting plate 20, a drive source 30, four sets of linkage mechanisms, connectors 50, four sets of suction cup sets 60, and a number of release agent nozzles 70;

[0030] Specifically, the fixture plate 10 is installed on the fixed mounting plate 20, and the fixed mounting plate 20 can be installed and connected with an external manipulator (not shown in the figure); the driving source 30 is arranged on the fixture plate 10 In this embodiment, the driving source 30 is preferably a cylinder; the connecting member 50 is arranged on the output shaft of the driving source 30;

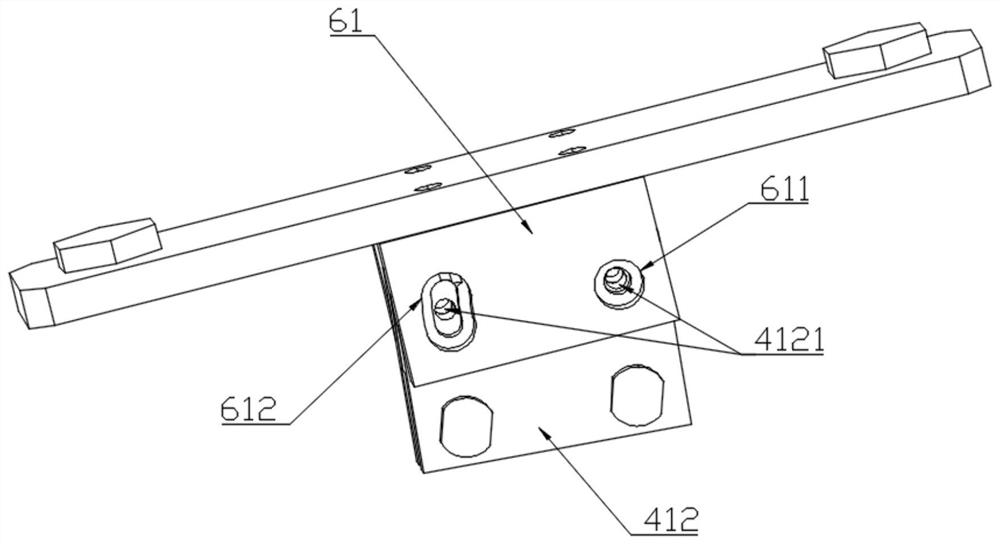

[0031] Specifically, each group of linkages includes a set of parallelogram linkages 41, fixed rods 42 and movable rods 43;

[0032] The parallelogram linkage mechanism 41 includes a first connecting rod 411, a second connecting rod 412, a third connecting rod 413 and a fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com