Gas-liquid two-phase flow phase change thermal cycle system

A gas-liquid two-phase flow and phase change heat technology, which can be used in measuring devices, instruments, etc., to solve the problems of difficult gas transportation and limited selection of gas compressors, and achieve the effect of precise control and measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

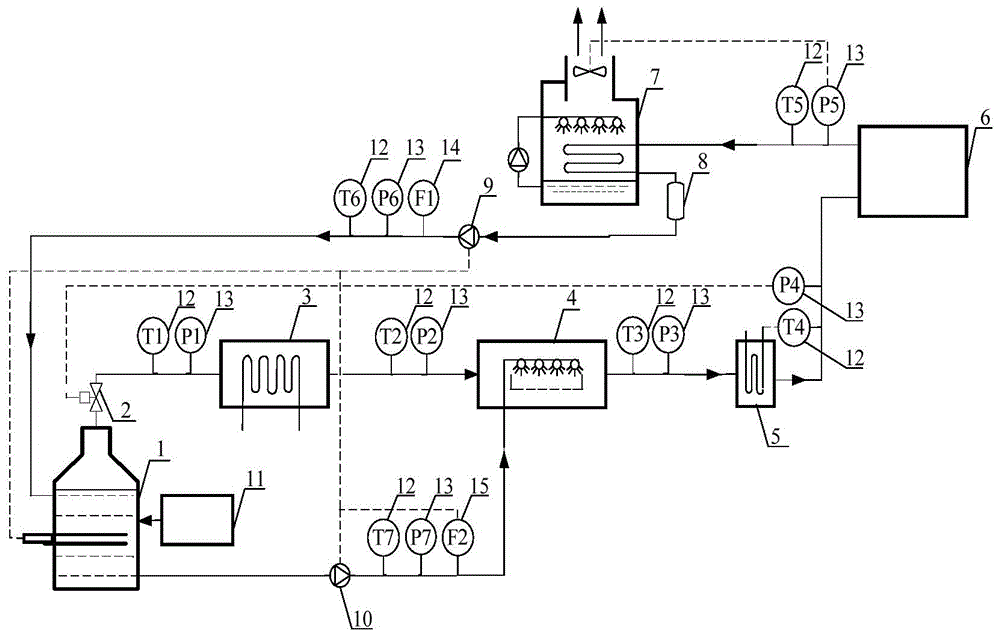

[0019] Now in conjunction with accompanying drawing, the present invention will be further described:

[0020] As shown in the figure, a gas-liquid two-phase flow phase conversion heat cycle system includes: steam generator 1, pressure reducing valve 2, steam superheater 3, humidification and desuperheater 4, temperature fine regulator 5, heat exchange 6, cooler 7, condensate storage tank 8, liquid frequency conversion circulation pump 9, humidification frequency conversion pump 10, deionized liquid preparation device and deaerator 11, multiple temperature sensors 12, multiple pressure sensors 13, liquid circulation volume Flow meter 14 and humidifier liquid flow meter 15, the pure liquid treated by the deionized liquid preparation device and deaerator 11 is sent to the steam generator 1 to generate saturated steam, and the saturated steam enters the steam superheater through the pressure reducing valve 2 3. Superheated steam with a dryness of 1 is formed in the steam superhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com