Spraying system and using method thereof

A technology of spraying system and spraying liquid, applied in the field of spraying system, can solve the problems of heavy workload, abnormal substrate quality, aggravated equipment loss and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the sprinkler system provided by the embodiment of the present invention and its usage method will be described in detail below in conjunction with the accompanying drawings.

[0040] Wherein, the size and shape of each component in the drawings do not reflect the true proportion of the sprinkler system, and the purpose is only to illustrate the content of the present invention.

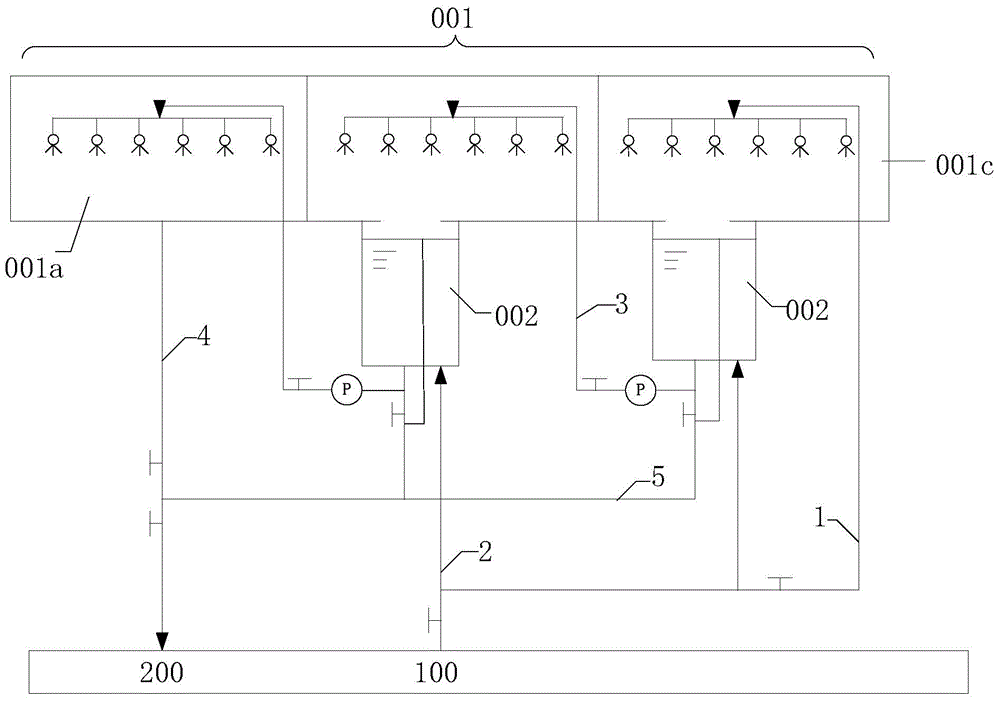

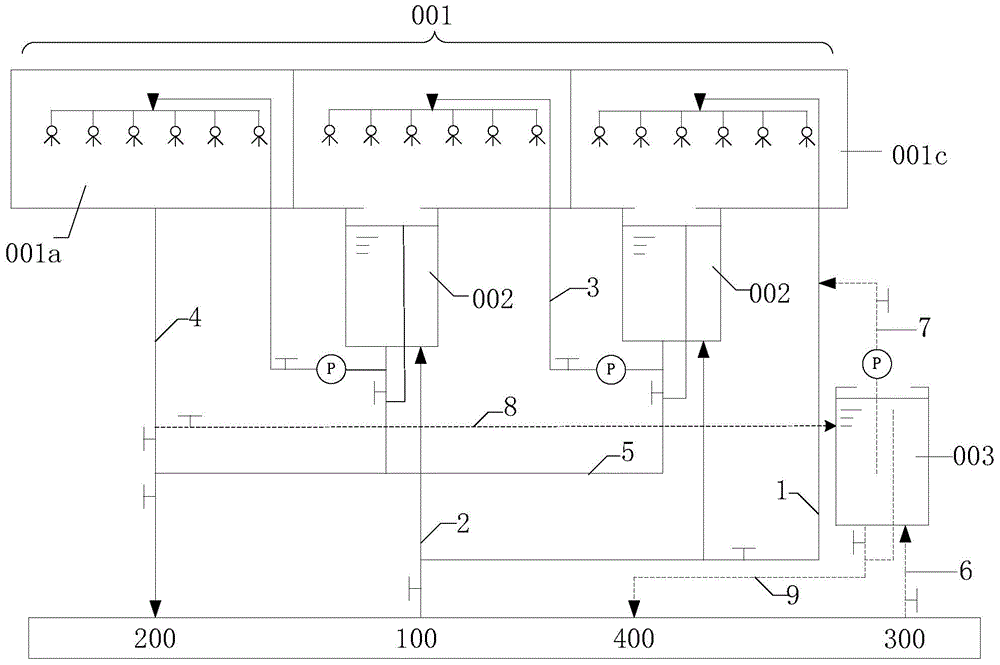

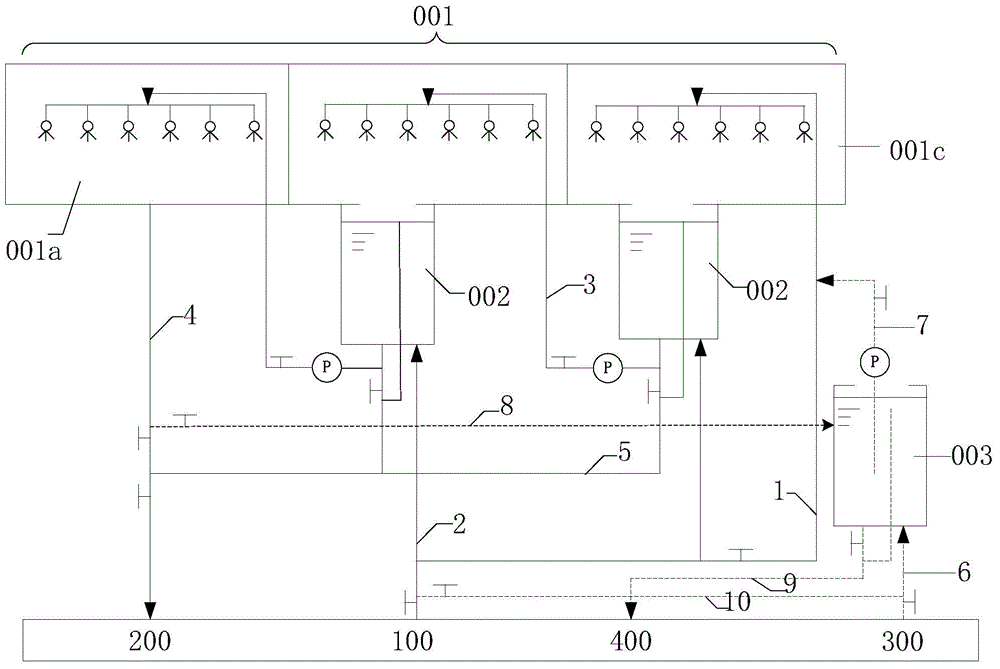

[0041] Embodiments of the present invention provide a sprinkler system, such as figure 2 As shown, it includes: a shower member 001 with a plurality of cascaded arrangements of a plurality of shower heads, ( figure 2 Only three spray components are shown, other spray components are not shown, and the total number of spray components is not limited here), spray liquid supply system, spray liquid recovery system, and control system, wherein the control system It is used to control the spray liquid supply system to provide spray liquid for spraying the sprayed su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com