A pillar moving method in the overall heat treatment process of a large spherical tank

An integral heat treatment and pillar technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of spherical tank damage, heavy weight of large spherical tanks, difficulty in manufacturing error control, etc., to achieve good moving effect, Correspondence stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

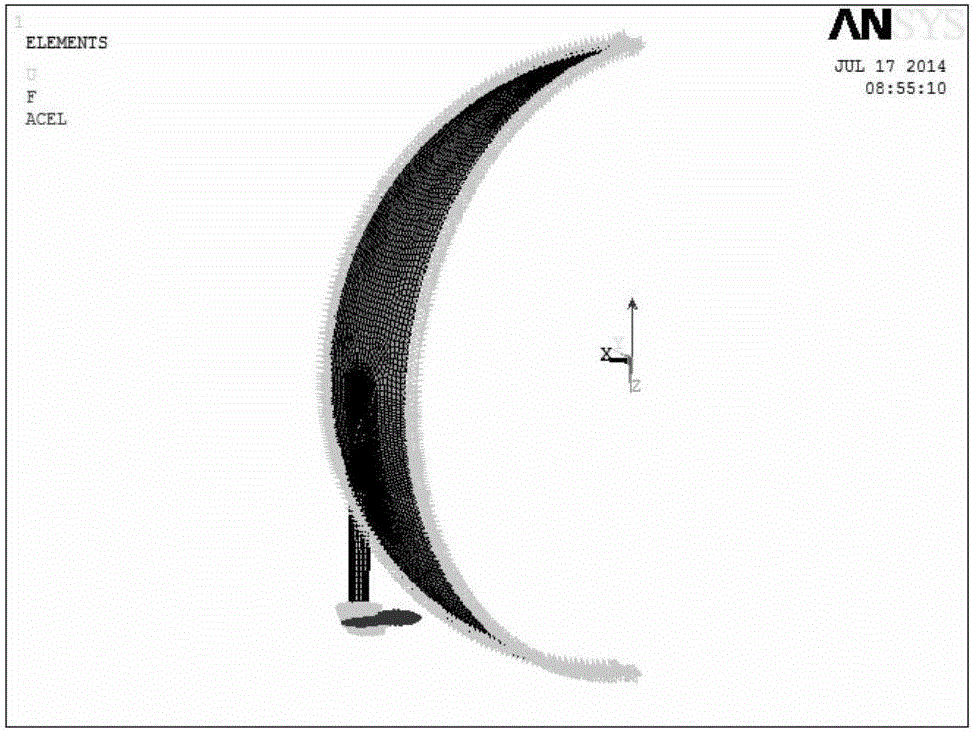

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0040] Take a certain 10000m 3 Taking a spherical tank as an example, formulate a plan for the movement of the pillars during the overall heat treatment process. The material of the spherical tank is Q345R, the diameter of the spherical tank is 26800mm, the wall thickness is 36mm, the net weight is 746215kg, and the number of pillars is 14.

[0041] S1. Determine the calculated friction force of the pillars supporting the spherical tank

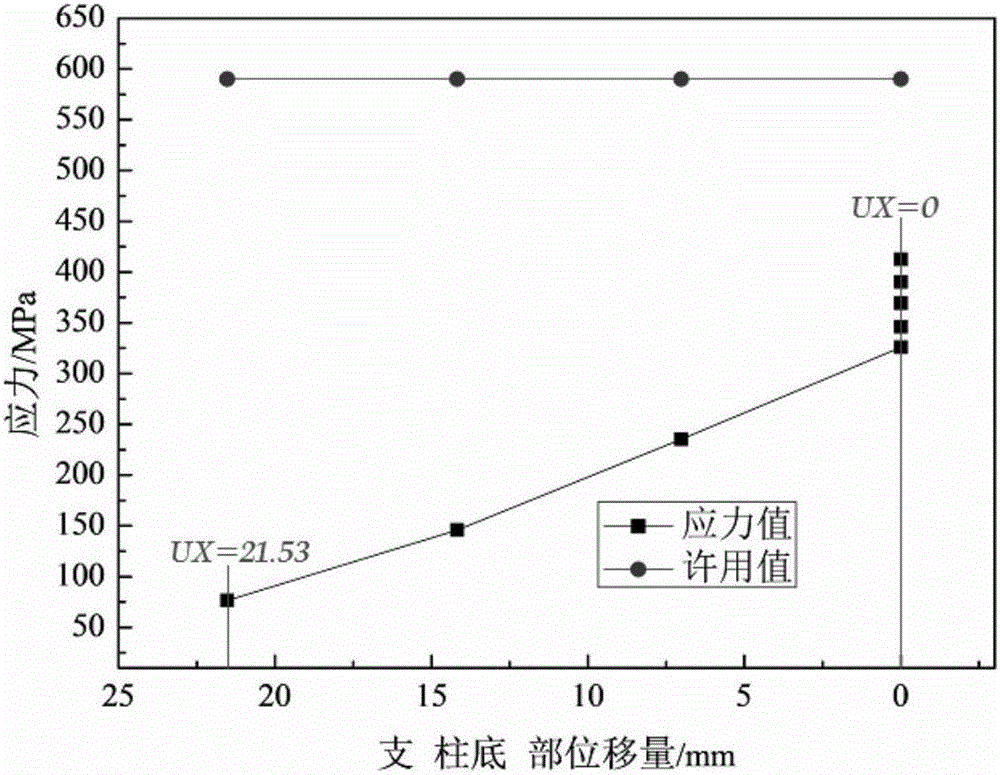

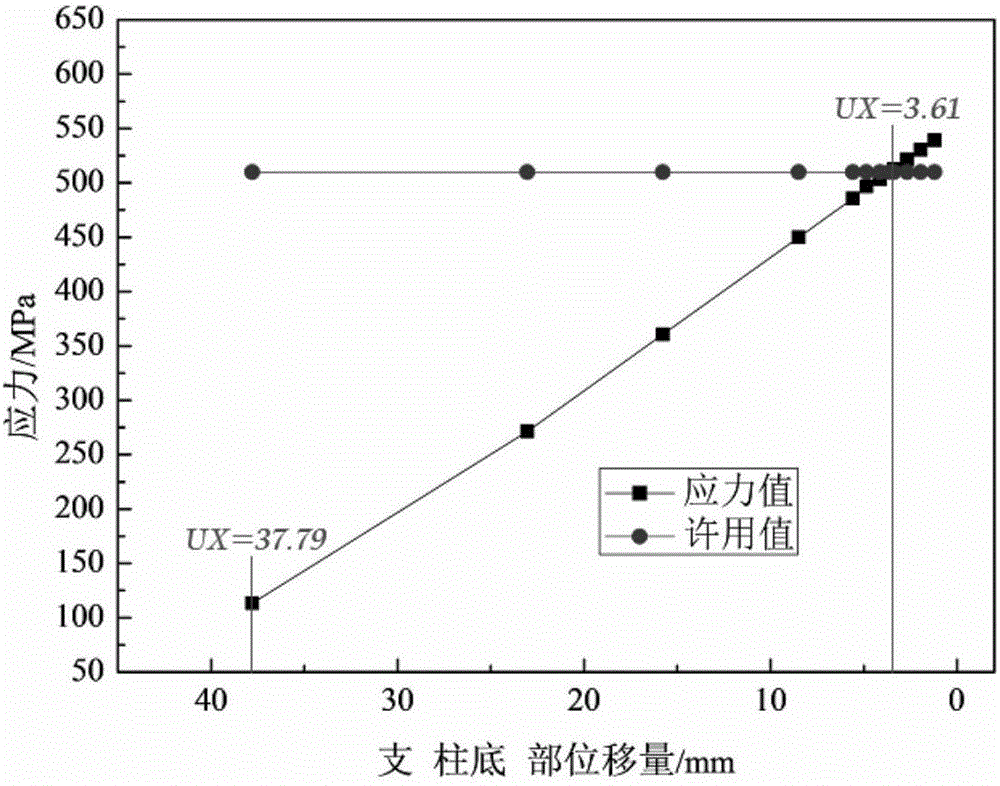

[0042] 1) According to the finite element numerical simulation method, when the spherical tank is at 200°C, the corresponding displacement of the bottom of the pillar under different friction forces is calculated, and the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com