Cable hanging joint

A cable and cable clamp technology, applied in the field of cable suspension fixing devices, can solve the problems of inconvenient position adjustment, reduced conductive effect, increased resistance, etc., and achieve the effects of saving manpower and material resources, convenient two-way adjustment, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

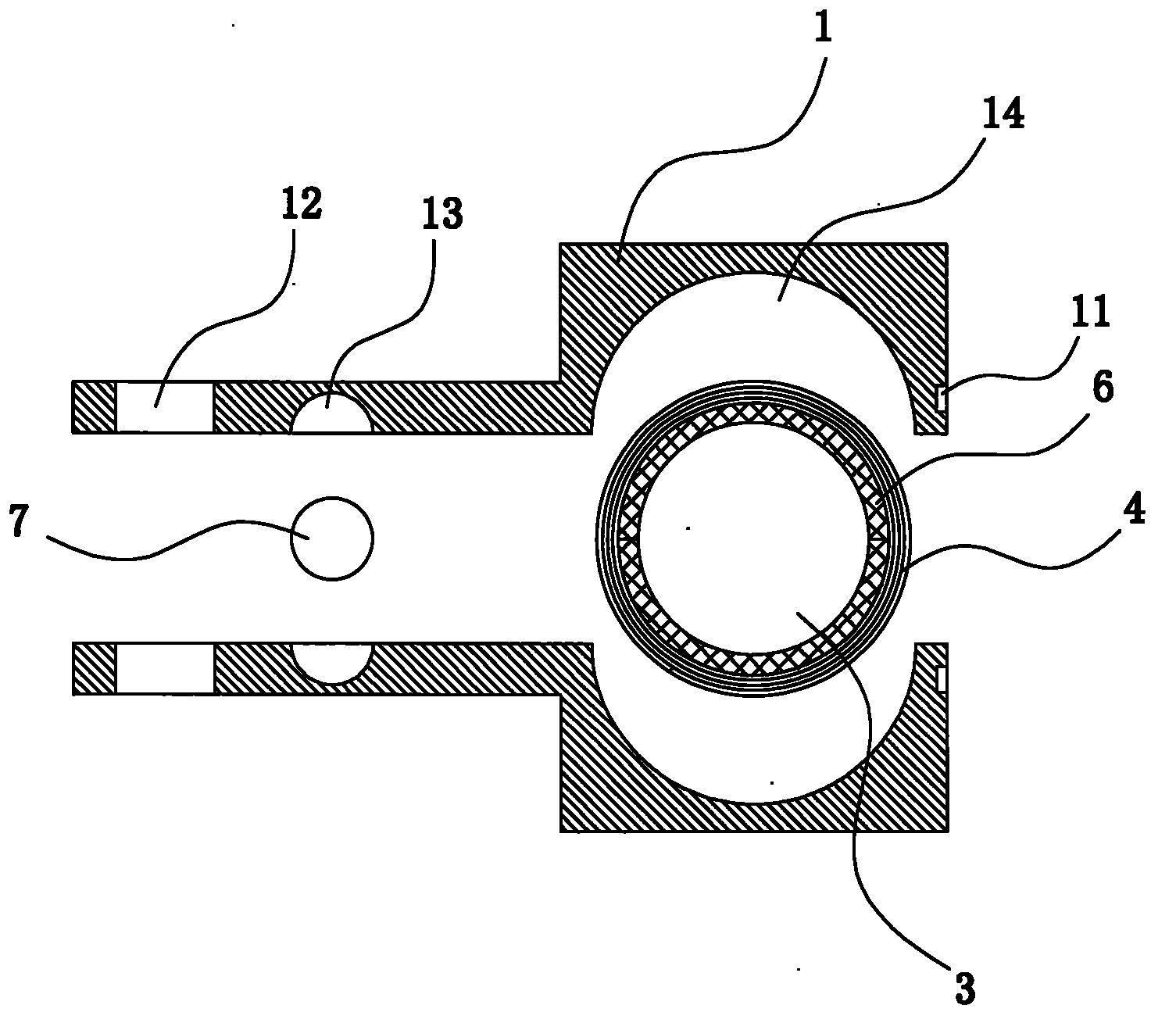

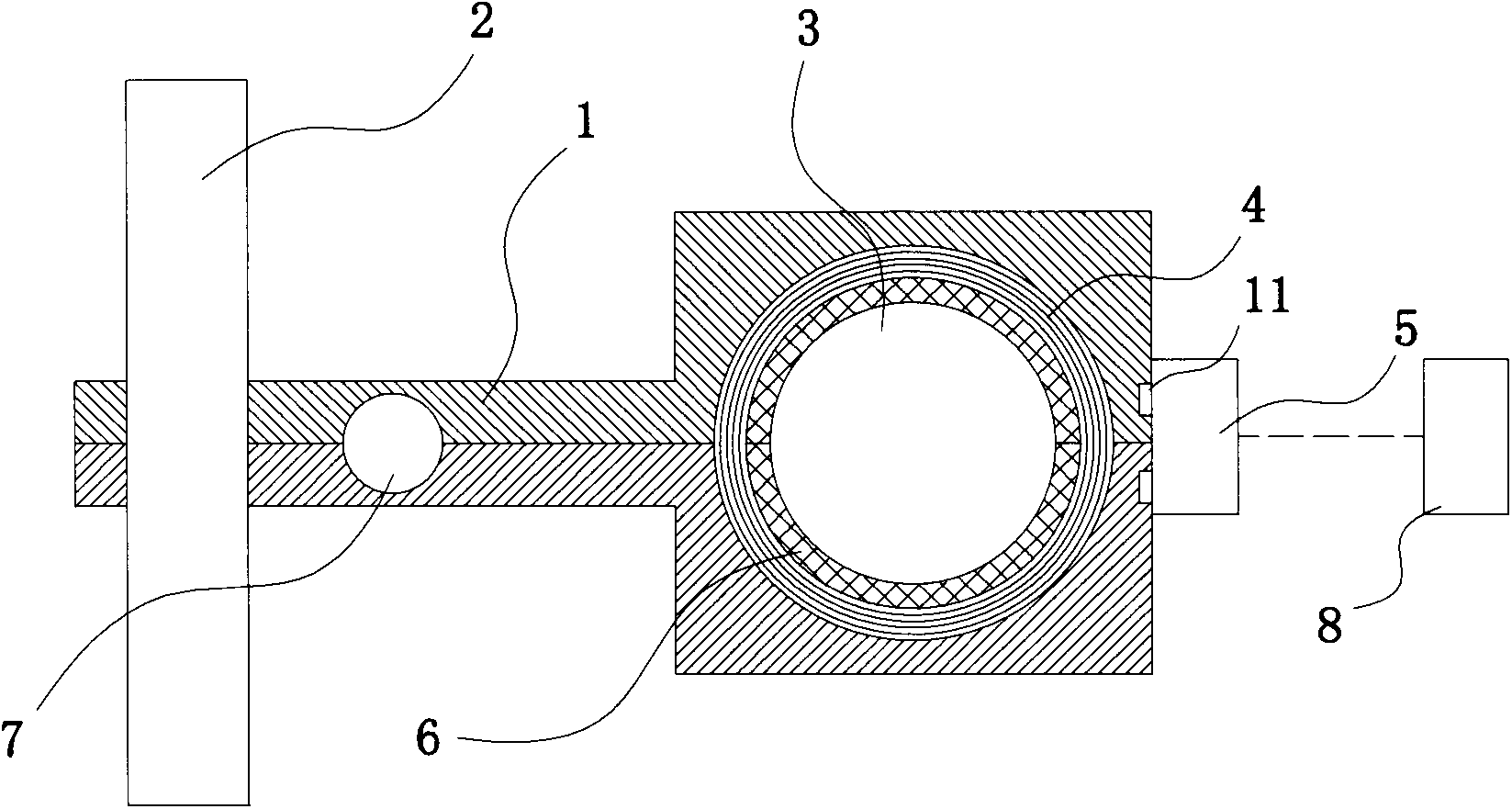

[0016] Such as figure 1 and figure 2 As shown, the cable suspension joint of this embodiment includes a joint body 1 formed by covering the upper and lower halves of the structure, and the joint body 1 has a cable clamping part and a mounting part;

[0017] There is a longitudinal cable clamping hole 14 in the cable clamping part, and a shielding ring 6 sleeved on the outer wall of the cable 3 is installed in the cable clamping hole 14, and the outer wall of the shielding ring 6 is wound and sleeved with a Hall coil 4;

[0018] The installation part has a longitudinal installation hole 13 and a vertical installation hole 12, the longitudinal installation hole 13 is installed on the vertical rod 7, and the vertical installation hole 12 is installed on the vertical rod 2; the joint body 1 is connected to the vertical rod 2 through the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com