Stud bolt connecting member and industrial furnace inner face repair method

A technology of stud bolts and connecting components, which is applied in the direction of connecting components, rod connections, threaded fasteners, etc., can solve the problems that welding operations take a lot of time, long hours, and difficult operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

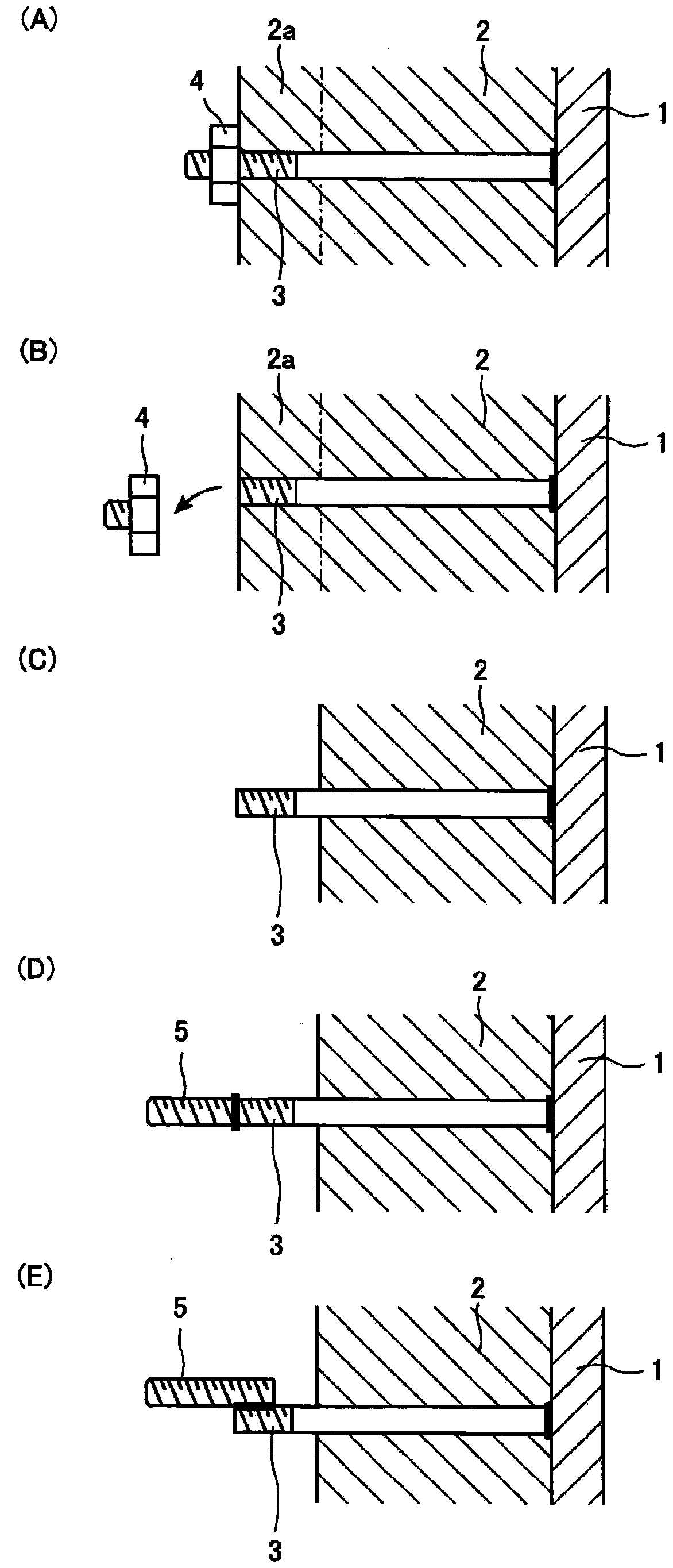

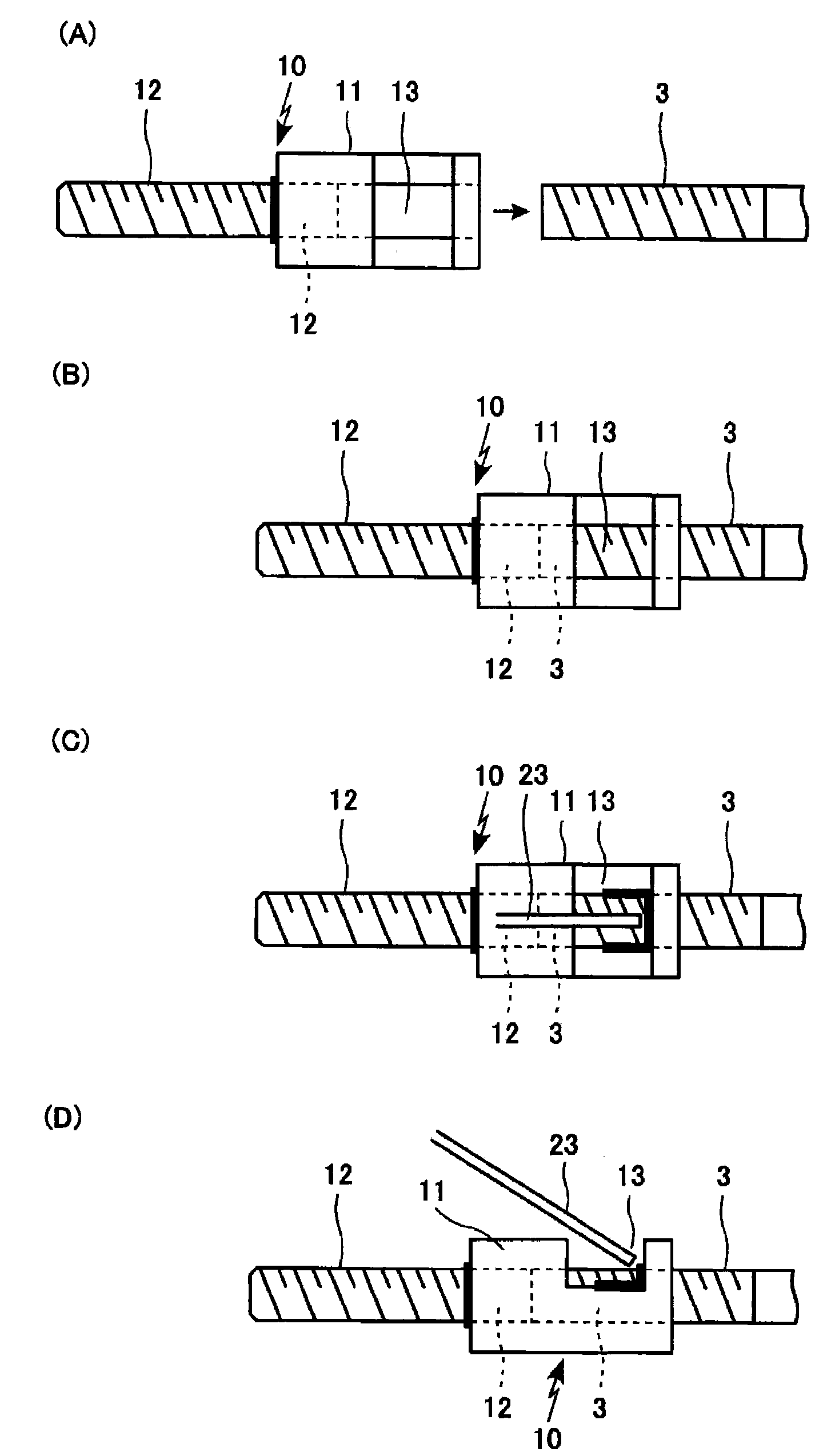

[0039] Hereinafter, the stud bolt connection member according to the embodiment of the present invention and the method of remodeling and repairing the inner surface of an industrial furnace using the stud bolt connection member will be specifically described based on the drawings. In addition, the stud bolt connection member of the present invention and the method of repairing the inner surface of an industrial furnace using the stud bolt connection member are not limited to the members and methods shown in the following embodiments, and can be used without changing the main concept of the invention. Make appropriate changes within the scope to implement.

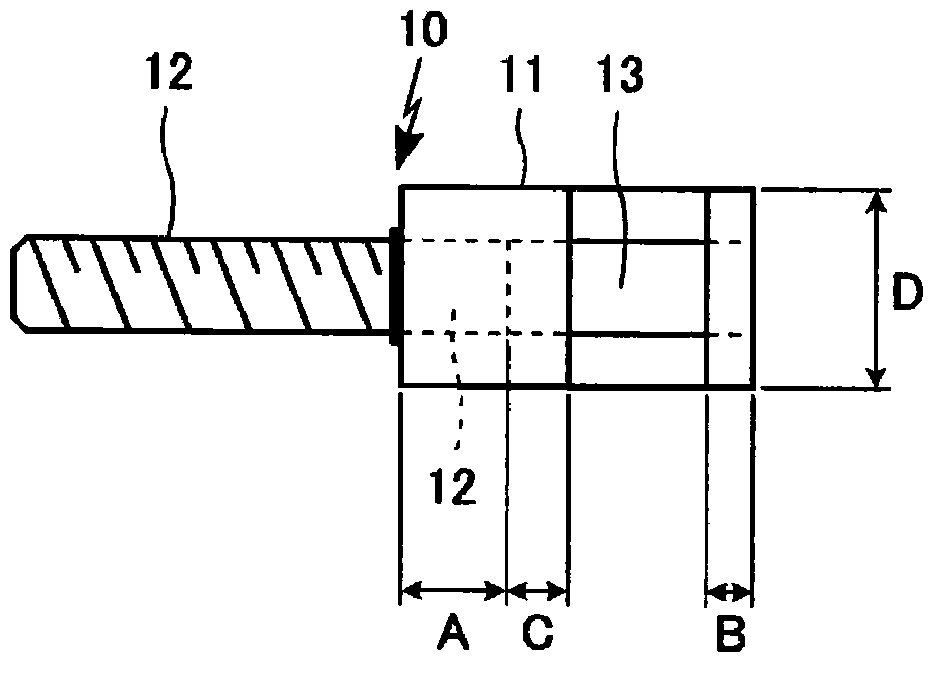

[0040] In the stud bolt connection member 10 of the present embodiment, as figure 2 As shown, the bolt portion 12 is protruded from the front end portion of the cylindrical connecting tube portion 11 into which the front end portion of the stud bolt 3 is inserted, and a screw for welding the stud bolt 3 to the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com