Peanut harvester

A peanut harvester and rack technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of low efficiency and high labor intensity, so as to facilitate centralized collection, reduce labor costs, and facilitate collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

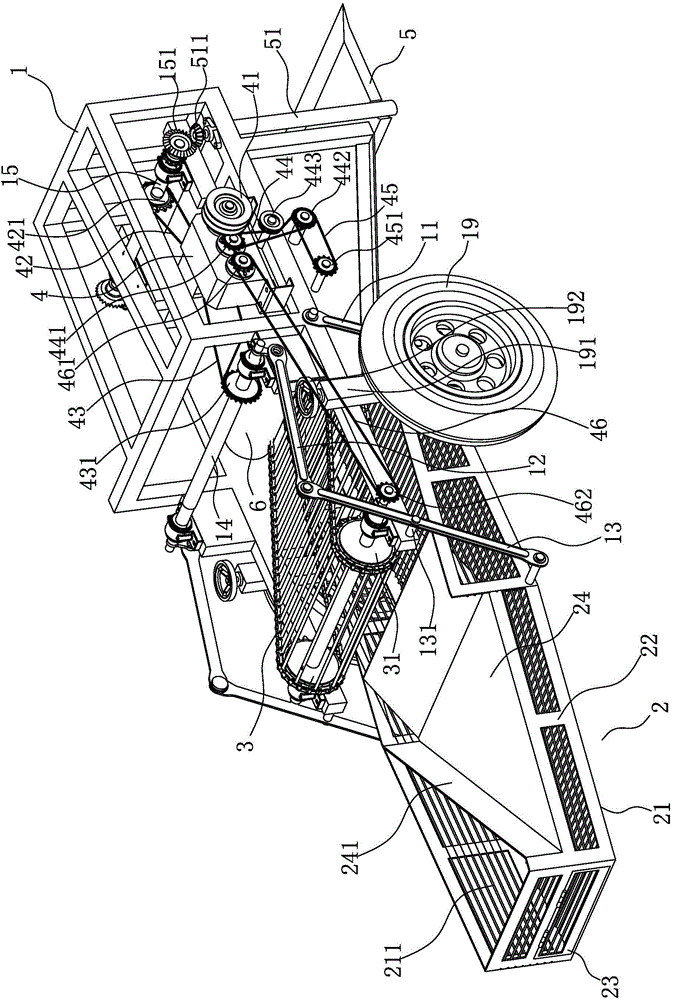

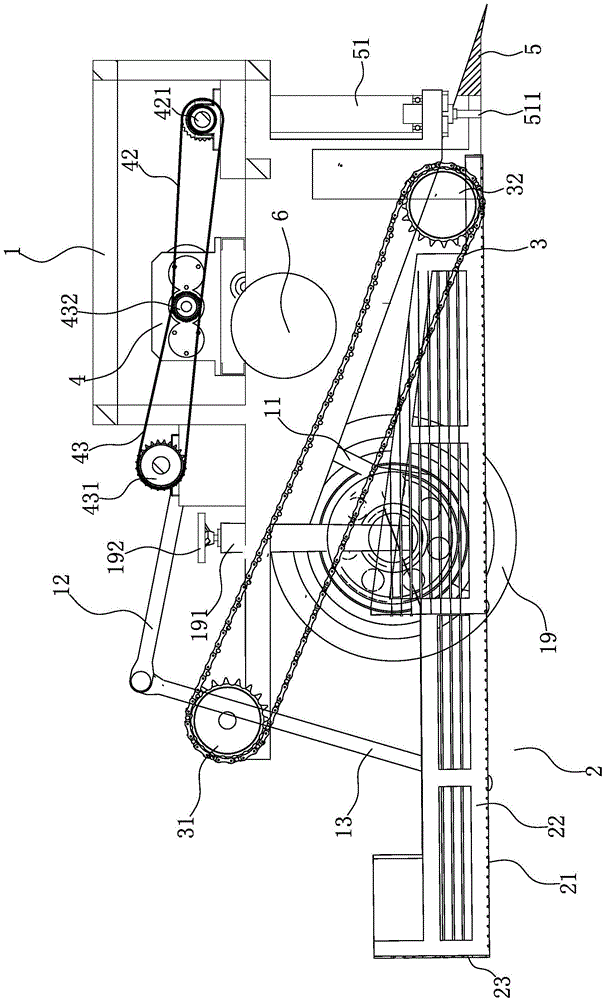

[0025] Such as figure 1 and figure 2 shown, see figure 1 , The peanut harvester of the present invention comprises frame 1, tire 19, bottom sieve 2, chain sieve 3, shovel plate 5 and tractor.

[0026] Frame 1 bottom is equipped with tire 19. Tires 19 are mounted on the frame 1 through tire posts 191 . The upper end of the tire column 191 is provided with a lifting handle 192 . The lifting handle 192 adjusts the height of the tire 19 through the screw structure of the tire column 191, and the tire column 191 includes a leading screw, a nut and a tire column shell. The lead screw is rotatably installed on the tire column housing. The tire column shell is used for guiding the nut, that is, the nut can only slide up and down in the tire column shell, the leading screw is threaded with the nut, the nut is rotatably connected with the axle of the tire 19, and the lifting handle 192 is fixed on the leading screw upper end.

[0027] The right end of frame 1 is fixed with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com