A flange nut tapping tool

A technology of flange nuts and tooling, applied in positioning devices, clamping devices, manufacturing tools, etc., can solve problems such as inability to guarantee verticality, and achieve the effect of high verticality accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

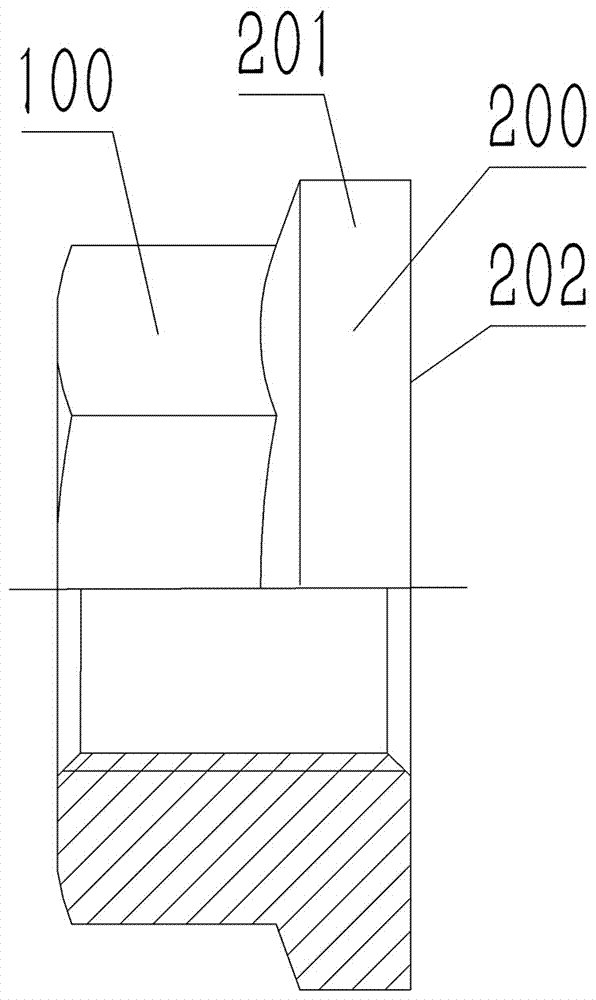

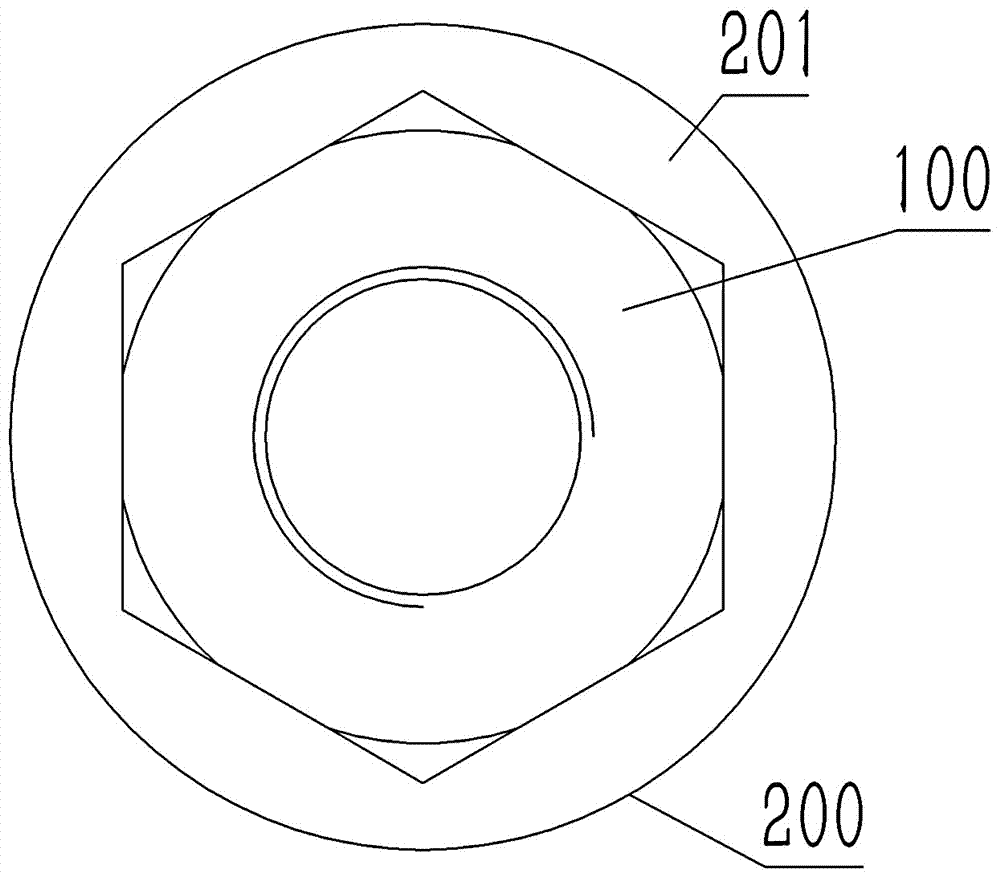

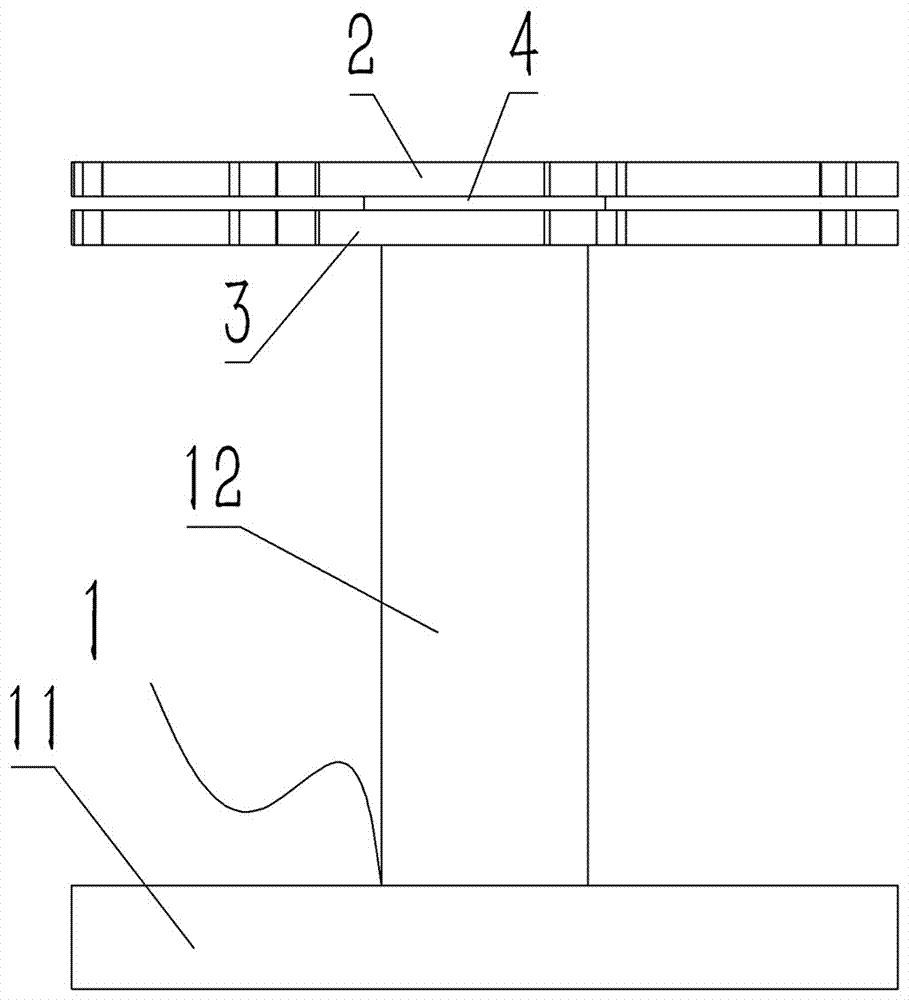

[0022] Embodiment of flange nut tapping frock among the present invention: as Figure 3 to Figure 6 As shown, the tool is a hexagonal flange surface nut drilling machine tapping tool, mainly composed of a fixed frame 1, an upper splint 2 and a lower splint 3, and the upper splint 2 and the lower splint 3 are fixed on the fixed frame 1 at intervals up and down. , and the upper splint 2 and the lower splint 3 are disc-shaped plates. The upper splint 2 is provided with a number of positioning grooves 21 evenly spaced along the circumferential direction. The groove width of the positioning grooves 21 gradually increases from the smallest one along the clockwise direction, and the positioning grooves 21 are the profiles for the flange nuts. The section is a vertically extending profile positioning channel for anti-rotation inserting in the axial direction, and the opposite side groove walls of the positioning groove 21 are used to guide the opposite sides of the outer peripheral su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com