Melt shunting sand cup in assembly

A technology of melt and sand cup, which is applied in spinneret assemblies, textiles and papermaking, feeding solution to spinnerets, etc. It can solve the problems of many impurities, increased broken ends, uneven single-filament fineness, etc., and achieve fineness Uniformity, uniform distribution, good melt flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

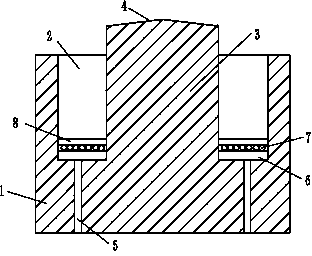

[0010] Combine below figure 1 Specific description embodiment:

[0011] Such as figure 1 As shown, a melt diversion sand cup in the assembly, the melt diversion sand cup in the assembly includes a cup body 1, and an inner cavity 2 is opened in the middle of the cup body 1, and the inner cavity 2 A cylindrical body 3 is provided in the middle, the upper end of the cylindrical body 3 protrudes outside the inner cavity, and the upper end surface of the cylindrical body 3 is a spherical body 4; the bottom of the inner cavity 2 is centered on the cylindrical body 3 Distributed with melt outlet holes 5, the bottom of the inner cavity 2 is located above the melt outlet hole 5 and a filter screen 6 is provided. Metal sand 7 is laid on the filter screen 6, and the upper part of the metal sand 7 is provided with There is a sealing net 8, and the filter screen 6, the metal sand 7, and the sealing net 8 are fastened together by high pressure. The outer edge of the filter screen is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com