Method for preparing diaminomaleonitrile

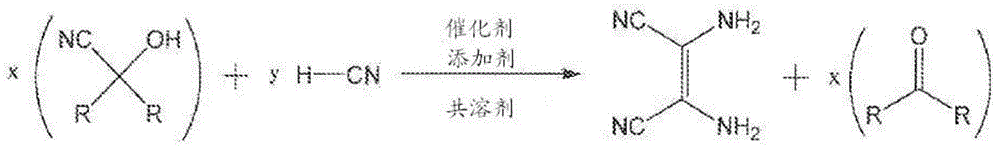

A technology of diaminomaleonitrile and its manufacturing method, which is applied to the preparation of carboxylic acid nitrile, the preparation of organic compounds, chemical instruments and methods, etc., which can solve the problems of restricting the acquisition of DAMN, and achieve the effect of easy implementation and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In an autoclave, 5 g of NaCN was added to 65 ml of acetone cyanohydrin. The solution was then stirred at 70°C for 4 hours. The solution turned brown. Excess acetone cyanohydrin was then neutralized by adding soda. The solution was then filtered and evaporated to give a brown solid (amount recovered 16.3 g, corresponding to yield = 85%).

Embodiment 2

[0035] In an autoclave, 10 g of NaCN was added to 130 ml of acetone cyanohydrin. Then 6.54 g of methyl mercaptan were added. The solution was then stirred at 60°C for 2 hours. The solution turned orange. Excess acetone cyanohydrin was then neutralized by adding soda. The solution was then filtered and evaporated to give an orange-yellow solid (amount recovered = 33.7 g, corresponding to yield = 88%).

Embodiment 3

[0037] In an autoclave, 28 ml of triethylamine was added to 130 ml of acetone cyanohydrin. The solution was heated to 40°C and stirred for 4 hours. The solution turned brown during the reaction. Then 300 ml of water were added and the aqueous phase was extracted with 3 x 150 ml of ethyl acetate. Combine the organic phases and use anhydrous MgSO 4 to dry. The solution was then filtered and evaporated. A brown solid was obtained (quantity = 31.3 g, corresponding to yield = 83%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com