Sheet feeding device and printer

A technology for sheet materials and delivery rollers, which is applied in the directions of printing devices, printing, transportation and packaging, etc. It can solve the problems of expanding the installation space and increasing the width of the push-down claws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

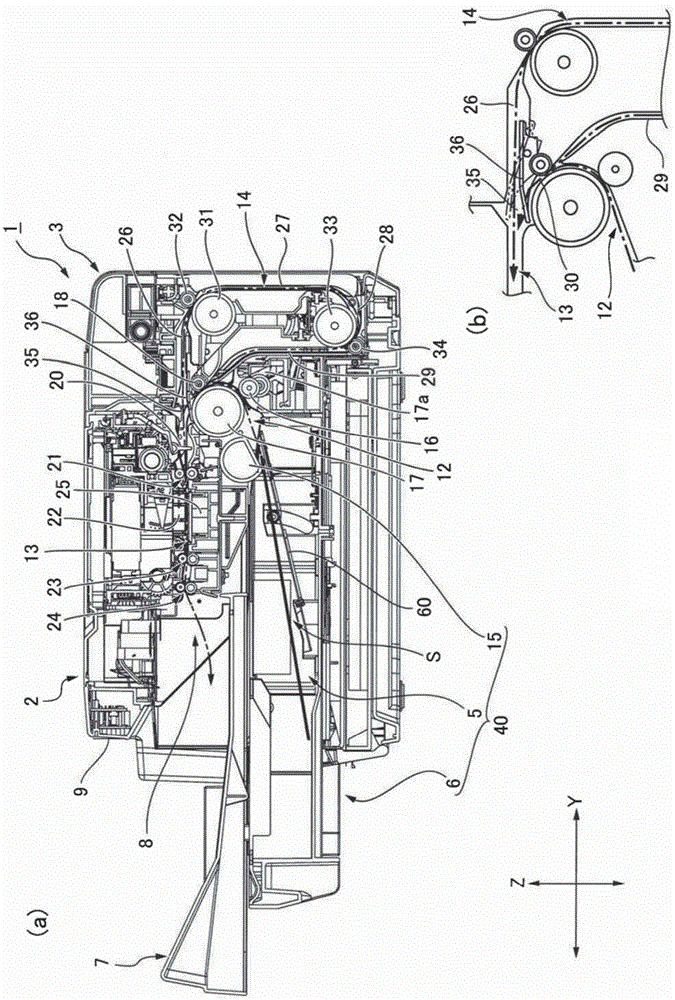

[0063] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The following embodiments are examples of an inkjet printer including a paper feeding device to which the present invention is applied. The present invention can also be applied to printers other than inkjet printers. In addition, the present invention can also be applied to a sheet feeding device that feeds sheets of checks, tickets, etc. other than a paper feeding device for recording paper, and a sheet processing device including the sheet feeding device.

[0064] 【Overall structure of inkjet printer】

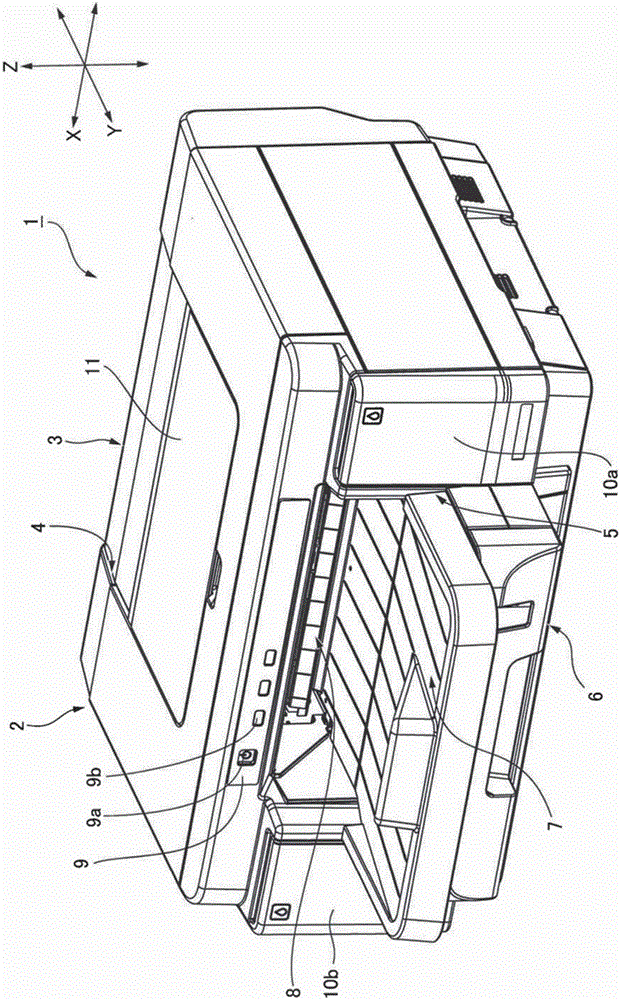

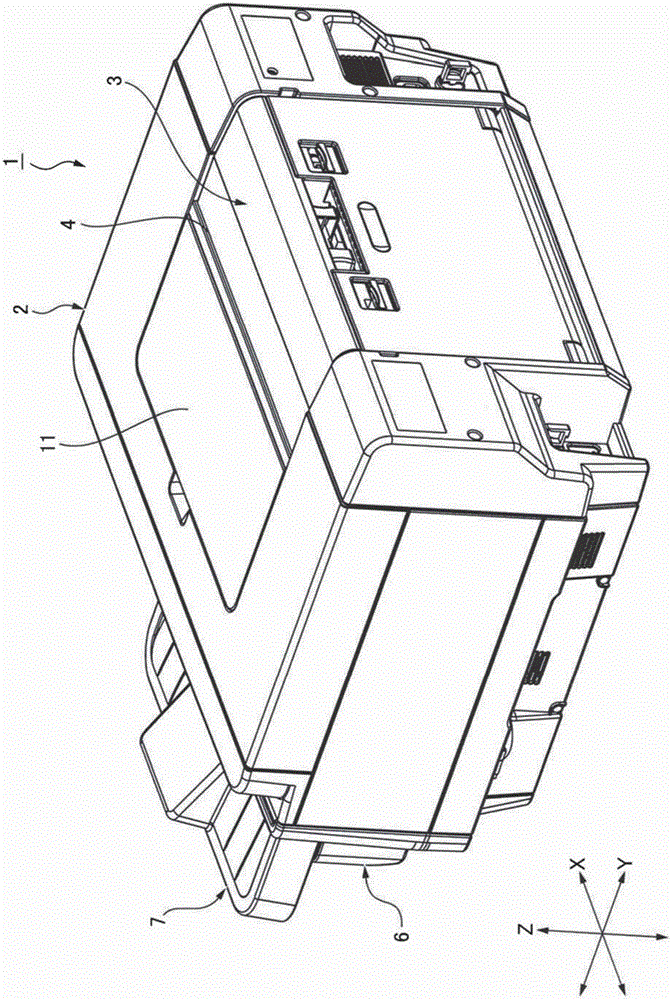

[0065] figure 1 is a perspective view of the appearance of an inkjet printer (hereinafter simply referred to as "printer") according to this embodiment as viewed from the front, figure 2 This is a perspective view of the printer's appearance viewed from the rear. in addition, image 3 (a) is a schematic longitudinal sectional view showing the internal structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com