The screw guider of the excavator fastens the impact frame to reciprocate the impact on the mining part

A technology of a guide and an excavator, applied in the field of machinery, can solve the problems of impact resistance, poor vibration resistance, safety accidents, and high block rate of a reciprocating impact excavator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

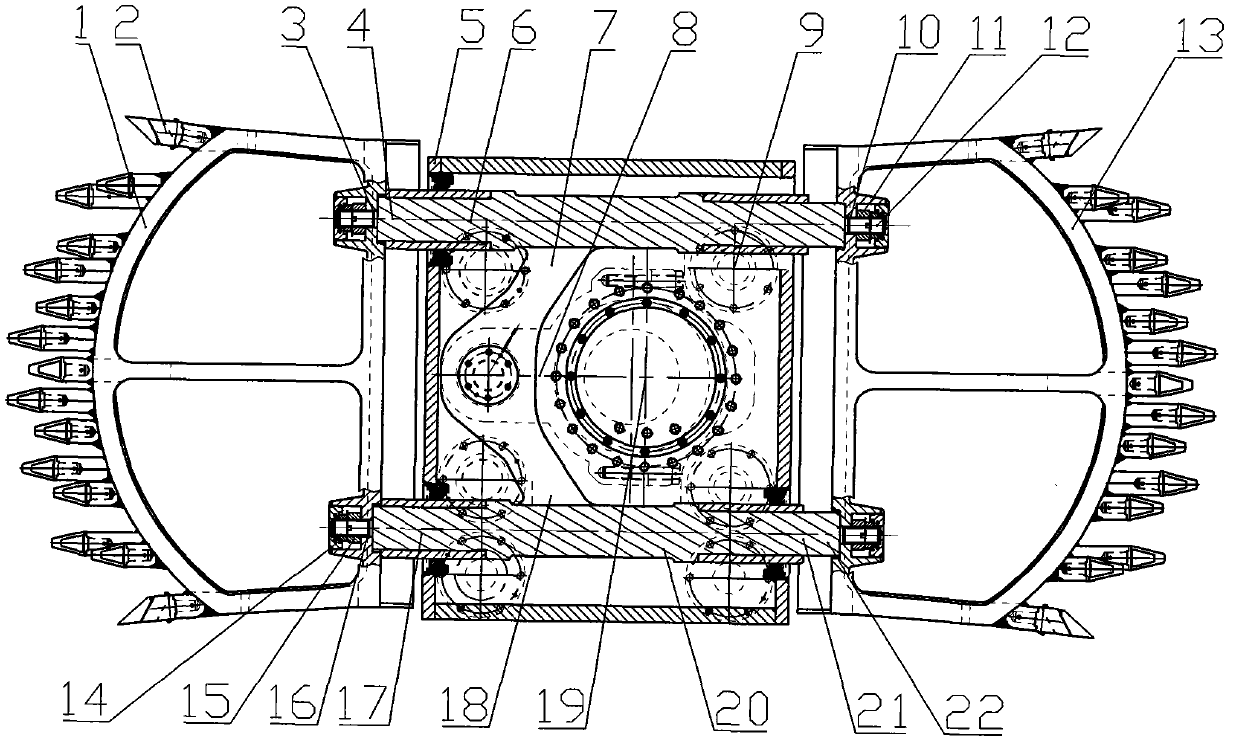

[0075] Figure 1 to Figure 2Fasten the impact frame for the screw guider of the mining machine described in Embodiment 1 to impact the excavation part back and forth. The excavator screw guide fastens the impact frame to reciprocate the impact mining part, including the box body 5, the power driver 19, the screw guide 20, the guide connector 18, the impact power source and the impact head 13, etc., and the impact head 13 includes the tooth punch seat. 1 and punching teeth 2, etc., the guide connector 18 and the power driver 19 are arranged in the box body 5, the screw guide 20 includes the screw guide A12 and the screw guide B22, etc., the screw guide A12 and the screw guide B22 are formed by the box The body 5 is supported, the screw guide A12 and the screw guide B22 are set up and down, the screw guide A12 and the screw guide B22 can also be set left and right, and when a plurality of impact heads 13 are arranged, the screw guide A12 and the screw guide B22 can also be arran...

Embodiment 2

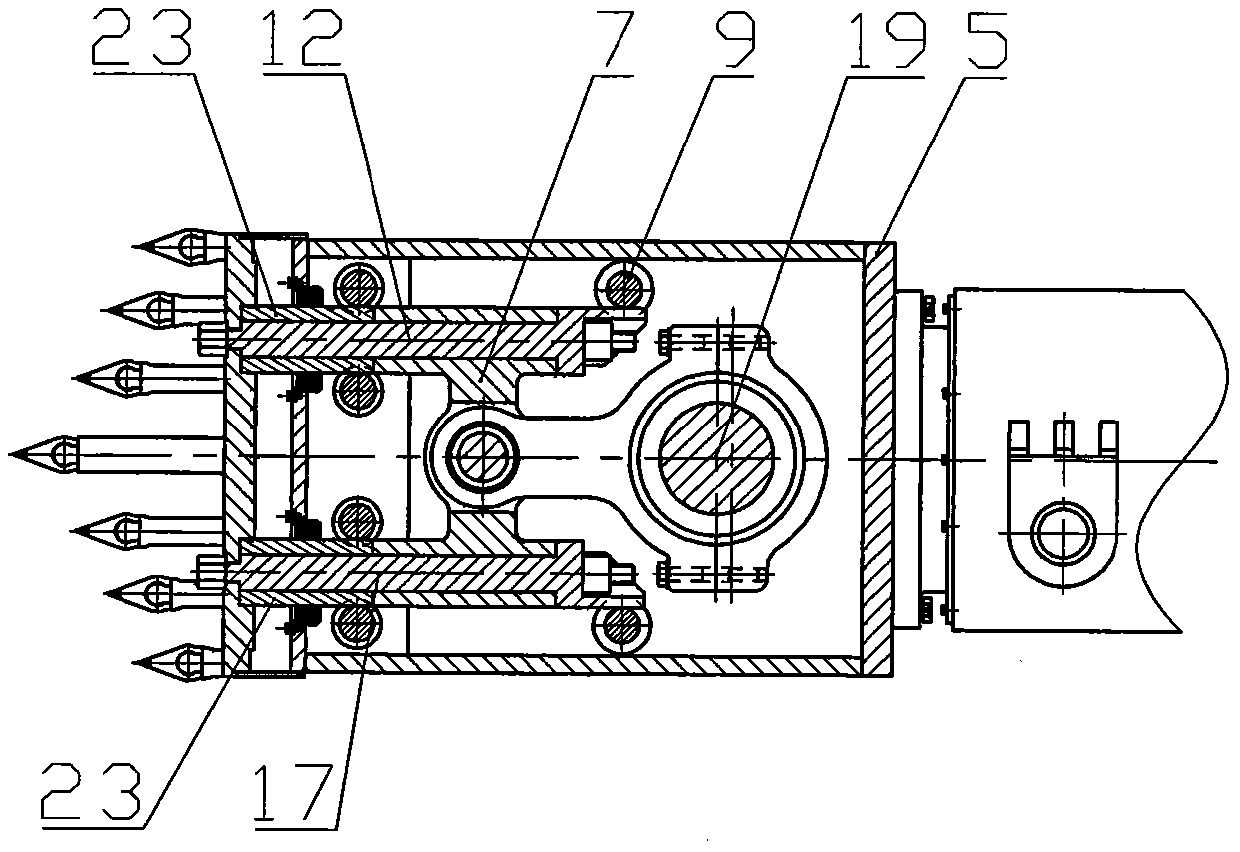

[0077] Such as image 3 As shown, the screw guider of the mining machine shown in Embodiment 2 fastens the impact frame to reciprocate and impacts the excavation part. The difference from Embodiment 1 is that the punch seat 1 can also include a guide rod positioning hole A24 and a guide rod positioning hole B26 etc. One end of the screw guide A6 is set in the guide rod positioning hole A24, one end of the screw guide B17 is set in the guide rod positioning hole B26, the screw guide A6 cooperates with the guide rod positioning hole A24, and the screw guide B17 and the guide rod positioning The hole B26 cooperates to increase the righting force of the screw guide A6, the screw guide B17, etc. against the tooth seat 1.

[0078] Others are with embodiment 1.

Embodiment 3

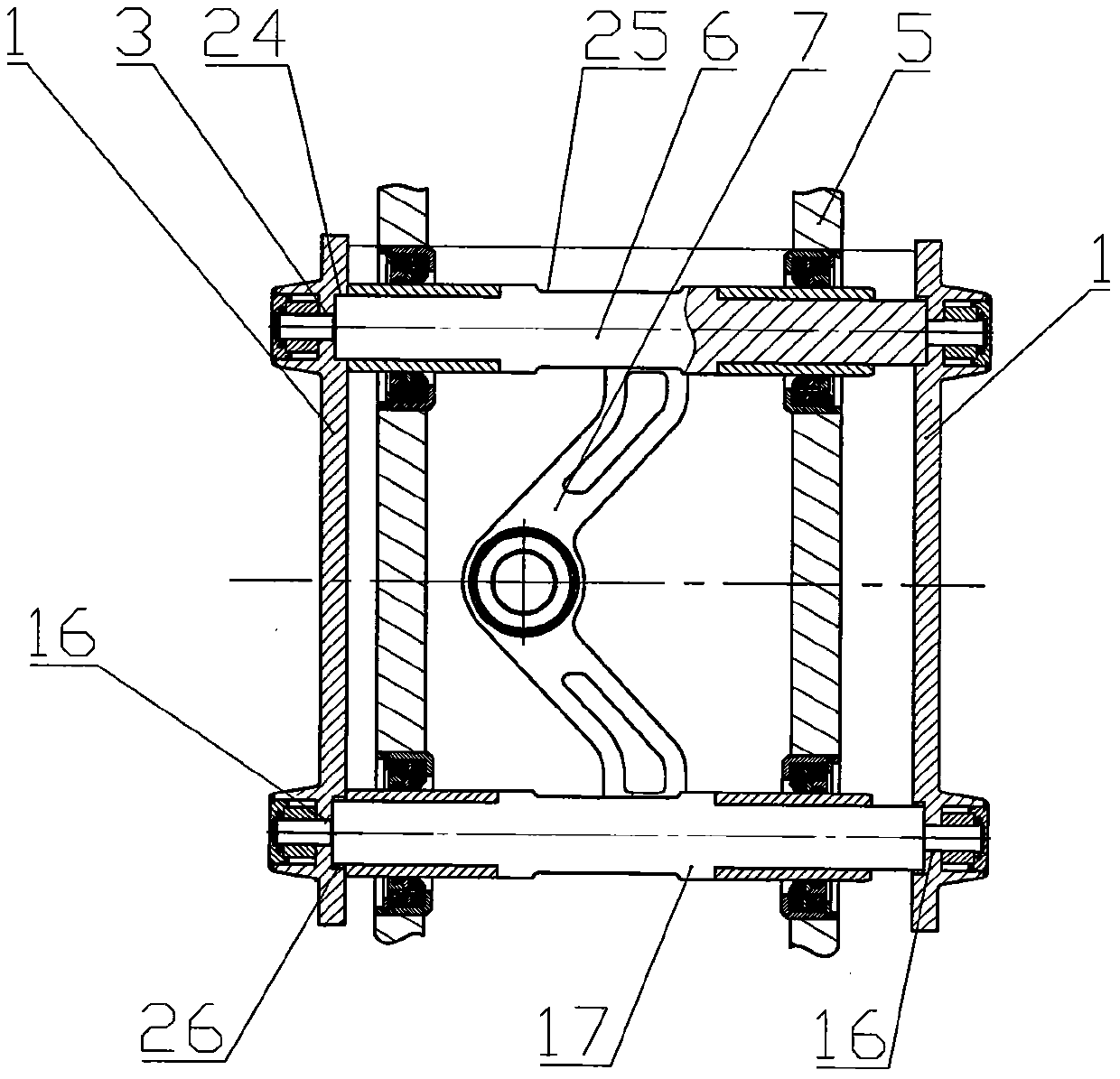

[0080] Such as Figure 4 to Figure 6 As shown, the screw guider of the mining machine shown in Embodiment 3 fastens the impact frame to reciprocate and impacts the excavation part. The difference from Embodiment 1 is that the punch seat 1 is provided with a counterbore 29, etc., and the guide nut 14 and the threaded rod 21 etc. in the counterbore 29 to fasten the reciprocating impact frame 25 tightly, the outer side of the counterbore 29 of the gear holder 1 is provided with a nut guard 28 etc., and a seal 30 etc. is provided between the nut guard 28 and the gear holder 1 . Such as Figure 4 As shown, the nut guard 28 is a punching tooth type nut guard 27; Figure 5 As shown, the nut guard 28 is a cover nut guard 31 .

[0081] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com