Fuel supplying device

A fuel supply device and fuel technology, applied in the direction of liquid fuel feeder, charging system, engine components, etc., can solve the problems of unachievable cost reduction, pulsation, noise, unstable bottom shape, etc., and achieve cheap pressure regulation performance , Excellent effect of mute performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

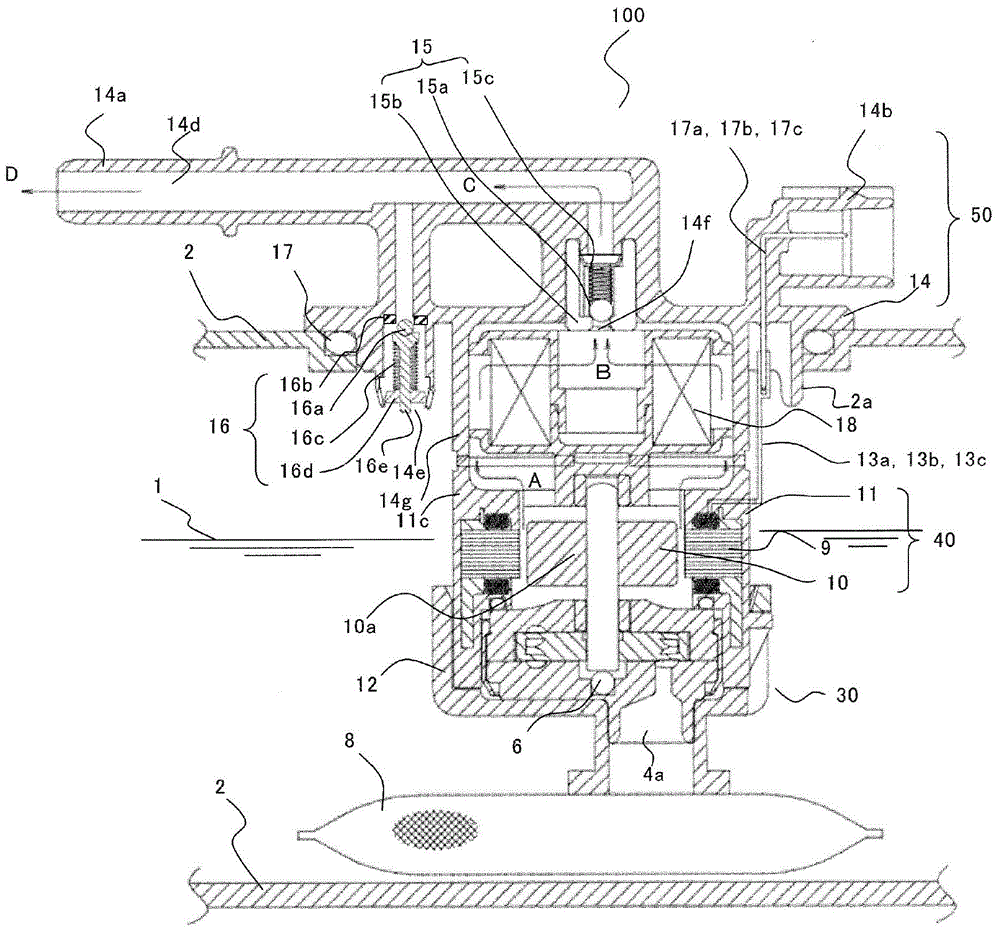

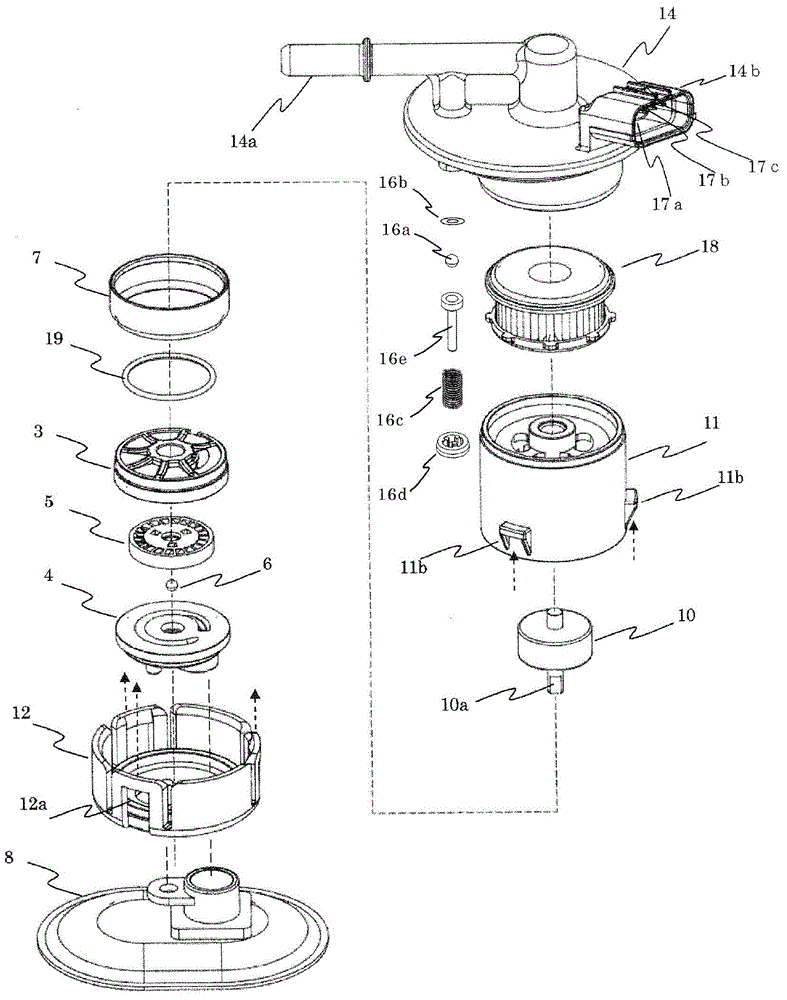

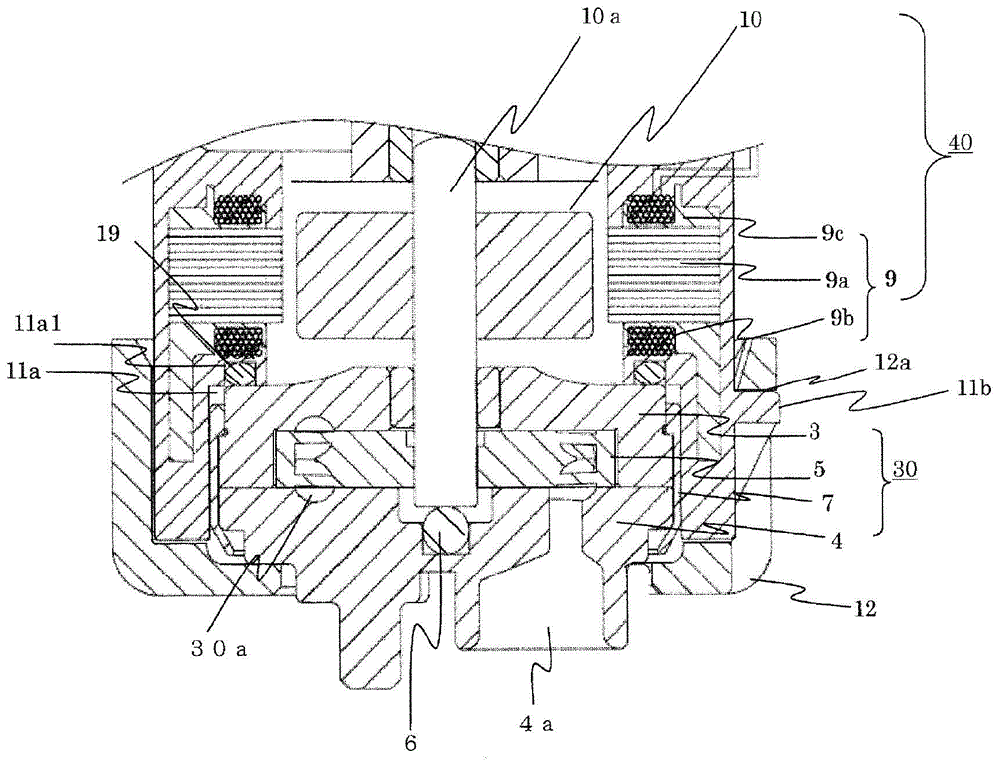

[0020] figure 1 It is a longitudinal sectional view of the fuel supply device in Embodiment 1 of the present invention, figure 2 Is an exploded perspective view of the fuel supply device in the first embodiment of the present invention, image 3 and 4 Yes figure 1 Enlarged view of the main parts of.

[0021] First, the structure of the fuel supply device 100 according to Embodiment 1 of the present invention will be described with reference to the drawings. in Figure 1 ~ Figure 4 Here, the fuel supply device 100 is hoisted on the opening 2a of the fuel tank 2 (shown partially broken) that stores the fuel 1 in a motorcycle, for example, and is composed of the following components: a pump part 30; a motor part 40, It serves as a driving source of the pump portion 30; and the flange portion 50 serves as an attachment member to be attached to the fuel tank 2.

[0022] The pump part 30 is constructed by accommodating the impeller 5 as a rotating part in the pump base 3 and the pump c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com