Automobile lamp module

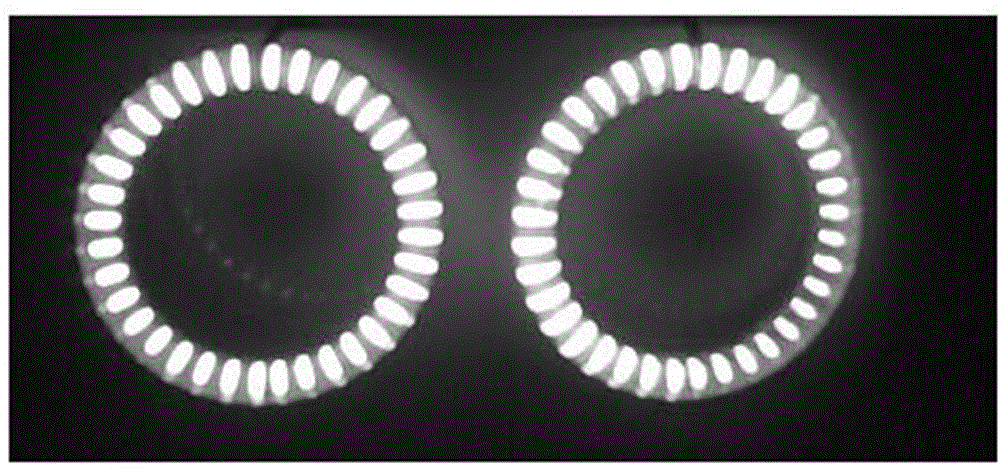

A module and lamp technology, applied in the direction of headlights, vehicle parts, lighting and heating equipment, etc., can solve the problems of affecting appearance and lighting effect, uneven brightness of fisheye aperture, obvious distribution of bright spots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

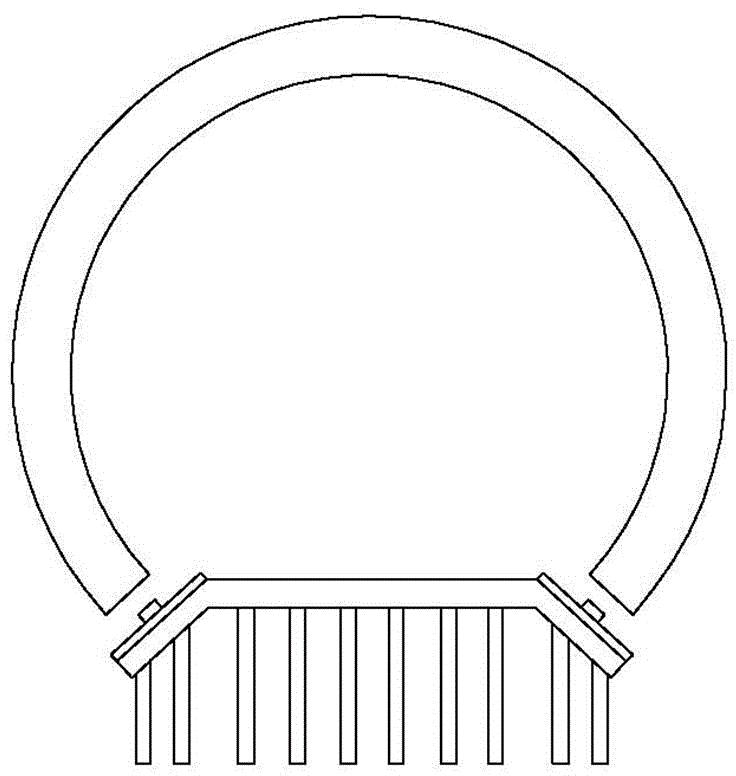

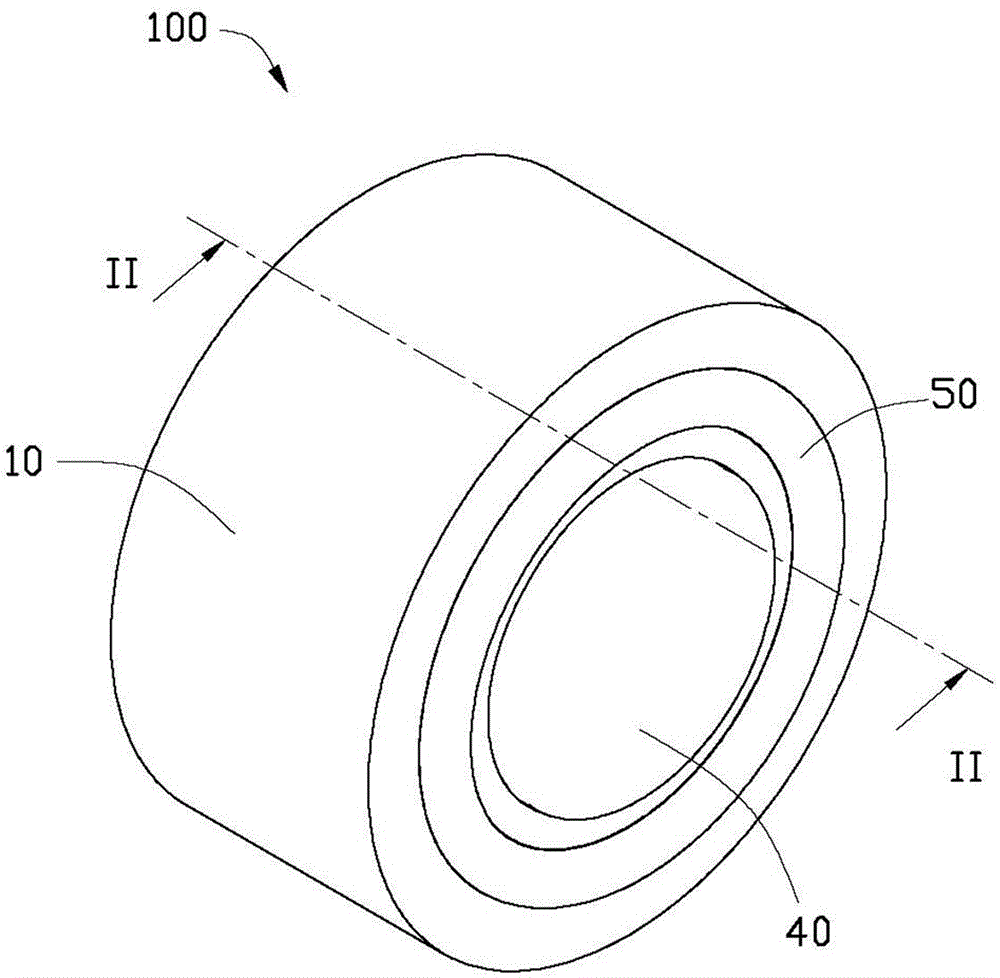

[0017] see image 3 and Figure 4 The vehicle lamp module 100 of the first embodiment of the present invention includes a lamp housing 10, a first accommodating cavity 12 formed by inwardly indenting the middle of the front end of the lamp housing 10, and a surrounding The annular second accommodating cavity 14 provided in the first accommodating cavity 12 , the first light source 20 accommodated in the first accommodating cavity 12 , and the second accommodating cavity 14 are accommodated The second light source 30, the first lampshade 40 fixed on the front end of the lamp housing 10 and covering the first light source 20 in the first accommodating cavity 12, and the front end of the lamp housing 10 and The second light source 30 covers the second lampshade 50 placed in the second accommodating cavity 14 .

[0018] The lamp housing 10 is integrally made of metal material or composite material. In this example, preferably, the lamp housing 10 is made of aluminum.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com