Automatic zero setting method of servo control system

A servo control system and automatic zero adjustment technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as poor accuracy and inability to achieve automatic zero adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

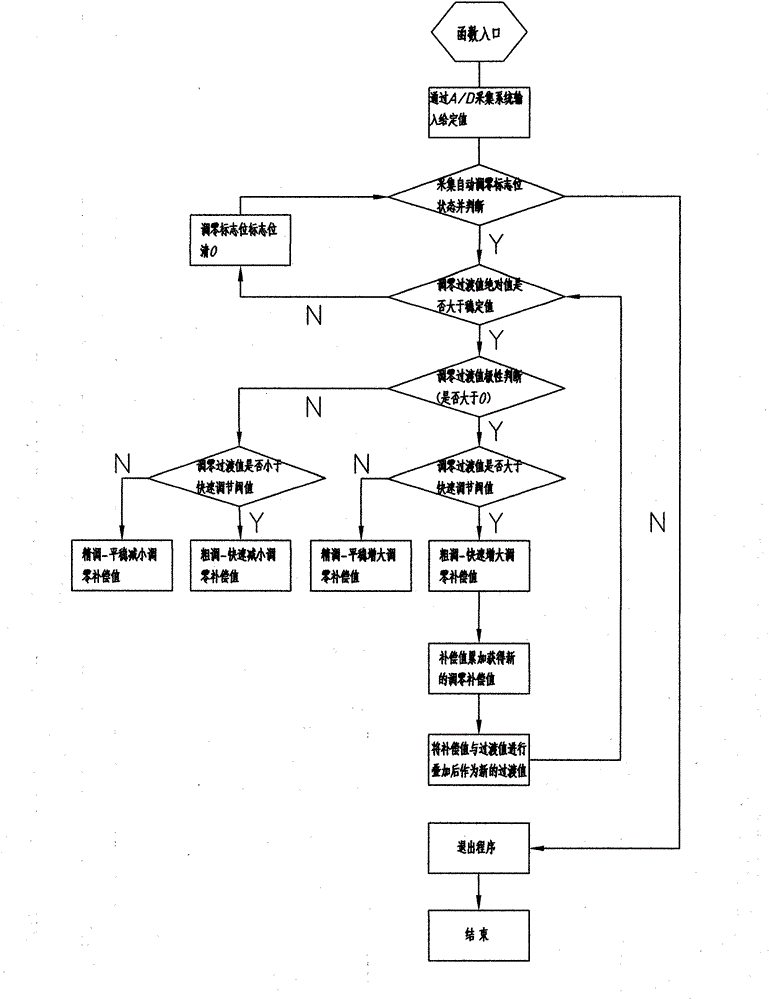

[0016] Such as figure 1 As shown, a method for automatic zeroing of a servo control system, the specific method steps are as follows:

[0017] (1) Input the given value through the A / D acquisition system

[0018] After the given control signal is processed by second-order filter, it is sent to the converter for A / D conversion, and the analog signal is converted into a digital signal quantity that the processor can recognize.

[0019] (2) Collect the status of the auto-zero flag bit and judge

[0020] After step (1) is completed, collect the flag status bit of the automatic zero adjustment and judge the status of the flag bit. If it is true, it will enter the next step of the zero adjustment program. If it is false, it will exit the automatic zero adjustment program and end.

[0021] (3) Whether the absolute value of the zero transition value is greater than the stable value

[0022] After step (2) is completed, compare the absolute value of the zero transition value with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com