Motor winding structure and winding method

A motor winding and winding technology, which is applied to the shape/style/structure of winding conductors, windings, electric components, etc., can solve the problems of large pre-tightening force and easy circuit breakage of windings, and achieve extended service life and high reliability , the effect of fewer tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the problem of large pre-tightening force when the winding is straightened, a structure of the motor winding and a winding method are proposed to avoid winding open circuit.

[0026] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

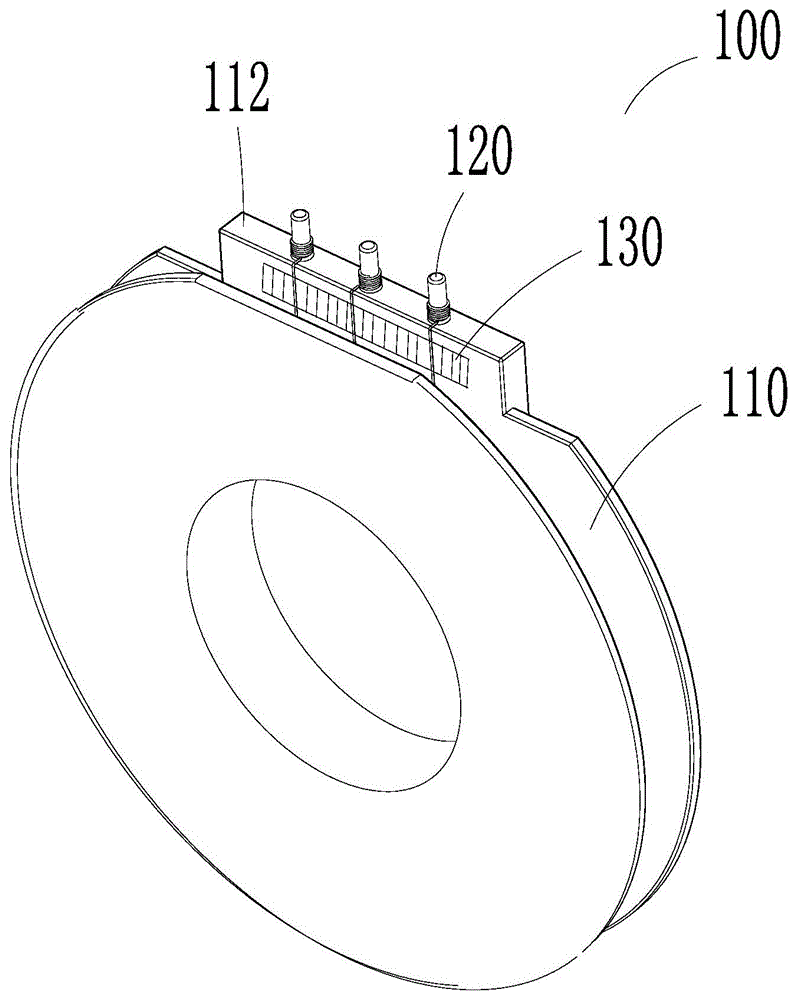

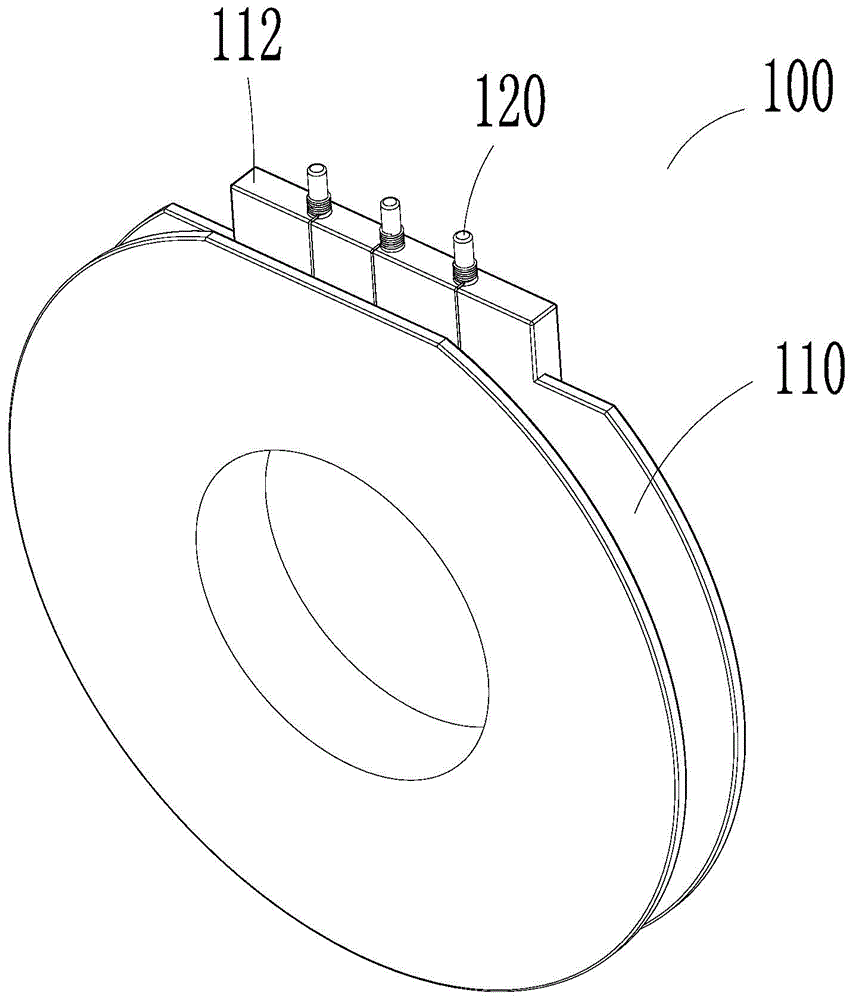

[0027] see figure 1 As shown, it is a three-dimensional schematic view of the first embodiment of the motor winding structure of the present invention. The motor winding structure 100 includes winding wires, a skeleton 110 and a terminal post 120 .

[0028] The skeleton 110 includes two disks, the centers of the two disks are connected by a winding shaft, and the diameter of the winding shaft is smaller than that of the disks. A boss 112 is provided on the edge of one of the disks, and the terminal post 120 is provided on the end face of the boss 112. The axis of the terminal post 120 is arranged perpendicul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap