Gas-solid two-phase jet type active fire resistance and explosion suppression method

An active, gas-solid technology, applied in fire rescue and other directions, can solve the problems of loss of explosion-proof effect, narrow effective application range of passive explosion-proof facilities, and no ability to dilute harmful gases, so as to dilute toxic and harmful gases and inhibit the spread of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

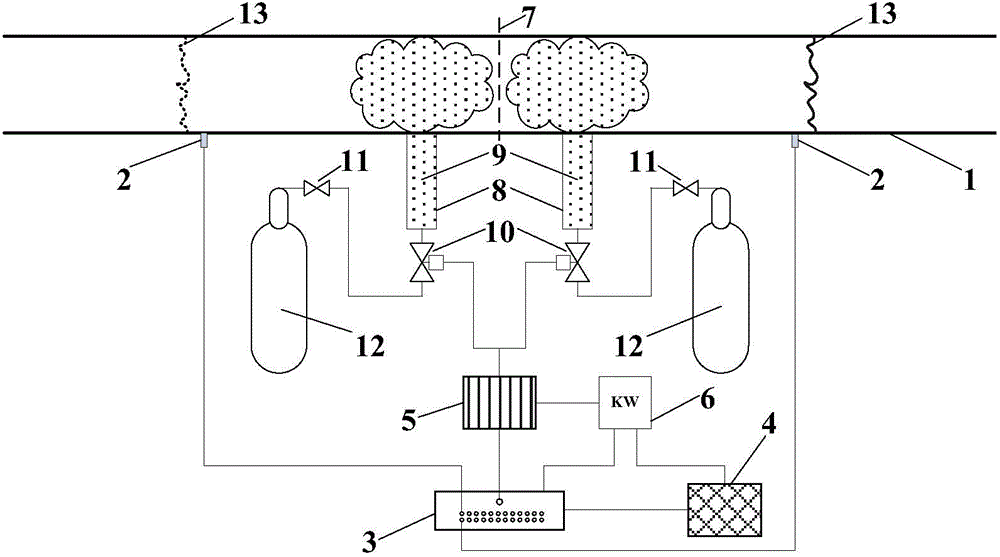

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The gas-solid two-phase jet active fire and explosion suppression method of the present invention has the following specific steps:

[0018] a. Two flame sensors 2 are arranged along the same horizontal line on the outer wall of the pipeline 1, the distance between the two flame sensors 2 is 62-122m, and the two flame sensors 2 are connected to the input port of the collector 3 to collect The Ethernet interface of the collector 3 is connected with the Ethernet interface of the signal processor 4, the output port of the collector 3 is connected with the input port of the controller 5, and the power ports of the collector 3, the signal processor 4 and the controller 5 are all connected to the explosion-proof The power supply 6 is connected;

[0019] b. The interface at the midpoint of the connection between the two flame sensors 2 is the central inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com