On-line roller distance dynamic fine adjusting device

A technology of fine-tuning device and roll distance, which is applied in the direction of rolling force/roll gap control, etc., can solve the problems of low wall thickness accuracy, cutting head and tail loss, etc., reduce investment, improve reliability and simplicity, simplify hydraulic pressure and The effect of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

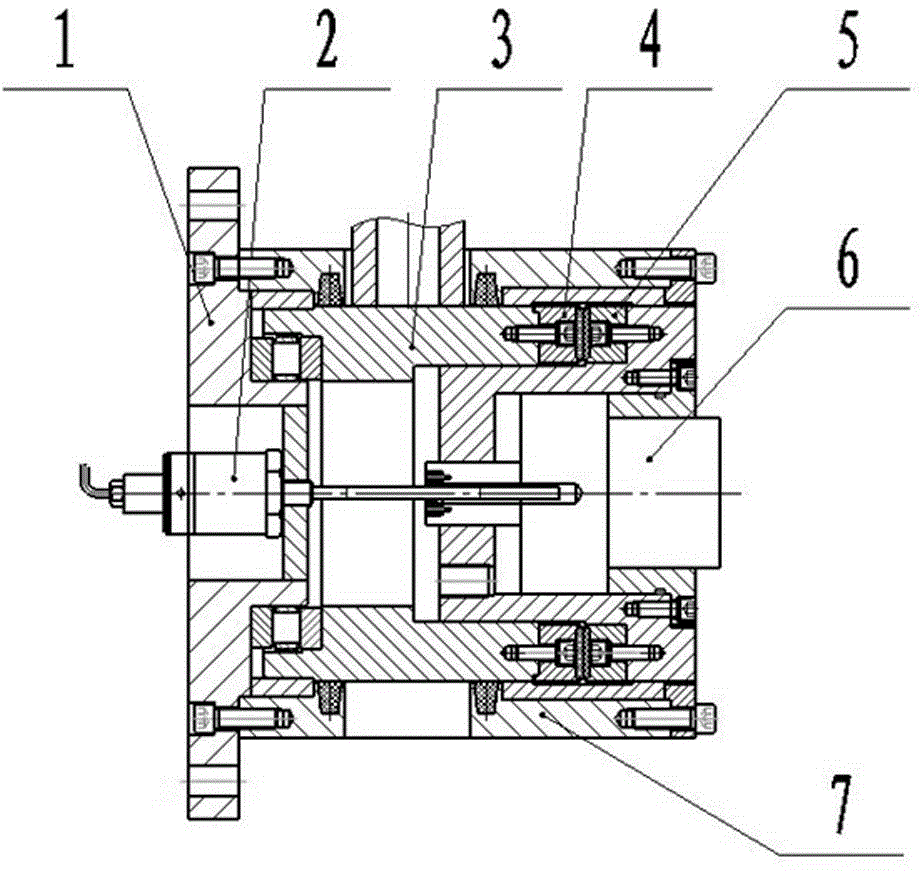

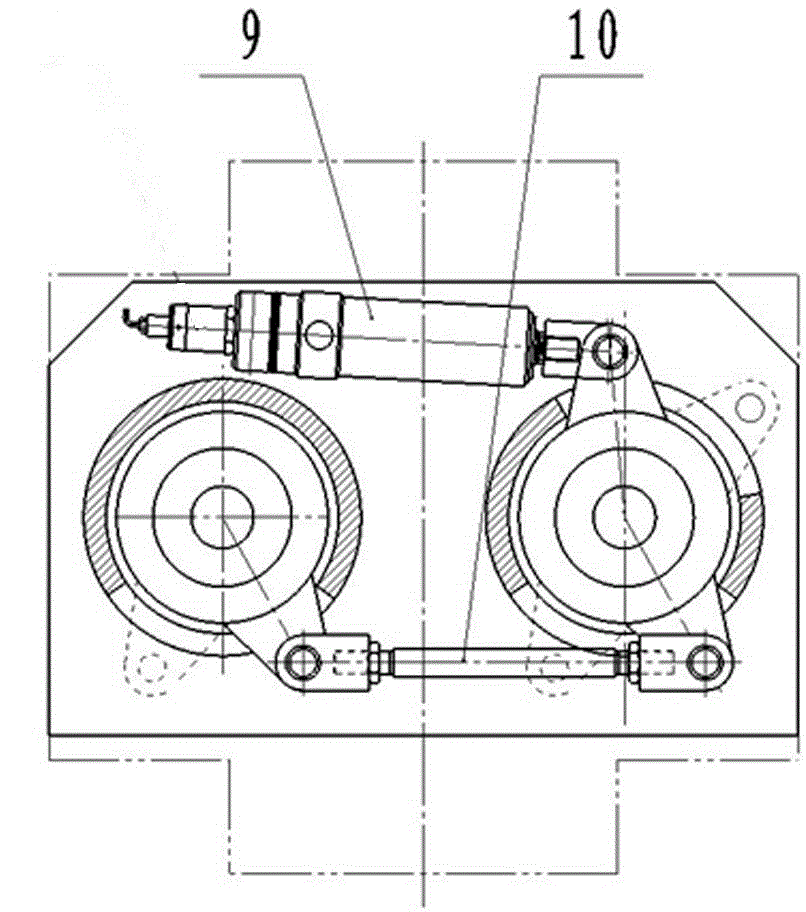

[0021] Such as figure 1 , 2 The on-line dynamic fine-tuning device for roll distance shown includes a rotary device 3 fixed in the housing, a rotating friction pair, and a quick-opening oil cylinder 6; ring 5; the rotary device 3 rotates in the housing 7 through bearings, and the rotating ring 4 is fixed on the end face of the rotary device 3; the quick-opening cylinder 6 is fixed in the housing by a limit key and can only Moving forward and backward along the axis, the stationary ring is fixed on the cylinder barrel of the quick-opening oil cylinder, wherein the end faces of the rotating ring and the stationary ring are installed opposite to each other.

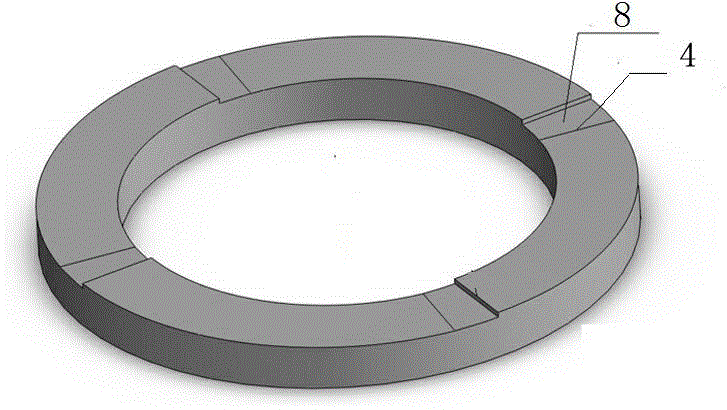

[0022] Wherein the end faces of the rotating ring 4 and the stationary ring 5 are helical surfaces of 3-8 segments, and an empty knife position 8 is arranged between each helical surface; a displacement sensor 2 is bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com