A coaxial dual-rotor structure

A technology of coaxial double rotors and rotors, applied in the field of aviation systems, can solve problems such as unseen coaxial double rotor structures, and achieve the effects of simple structure, high control precision, and low manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

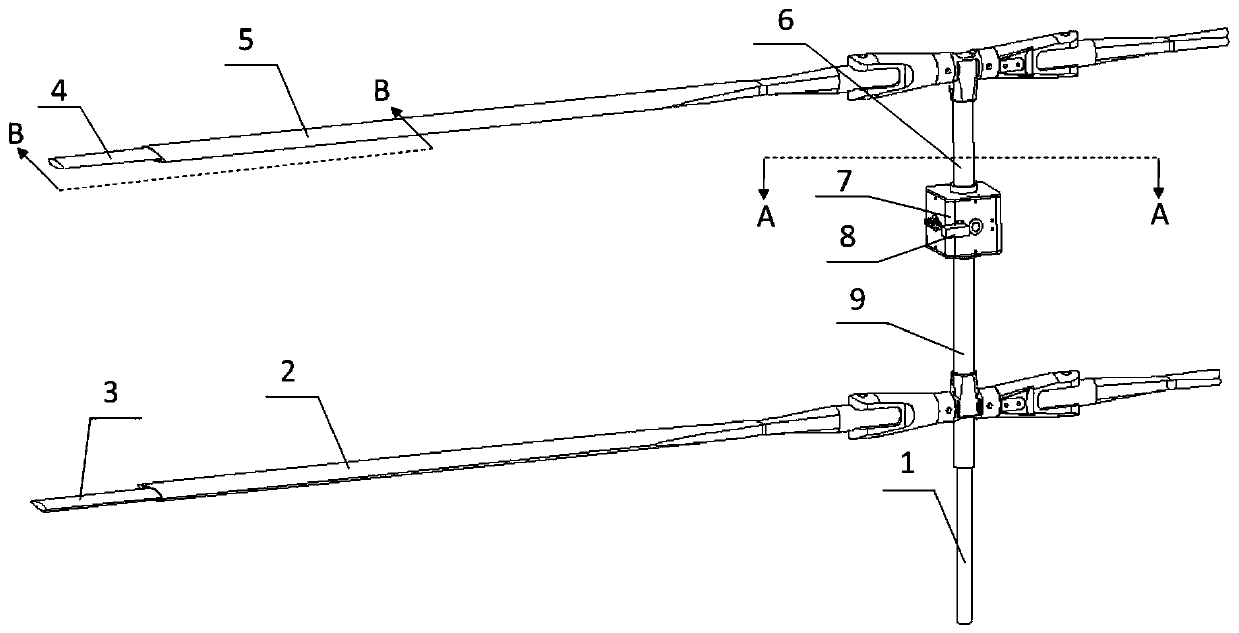

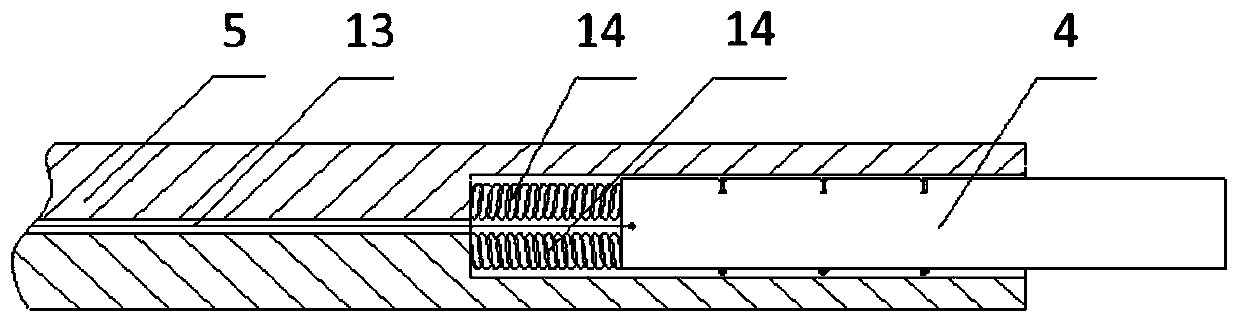

[0029] A coaxial double-rotor structure is provided, which comprises a coaxial upper main rotor 5, a lower main rotor 2, an upper rotor shaft 6, a lower rotor shaft 9, a central shaft 1, an upper bevel gear 16, a reversing bevel gear 17, Lower bevel gear 20, upper winglet 4, lower winglet 3;

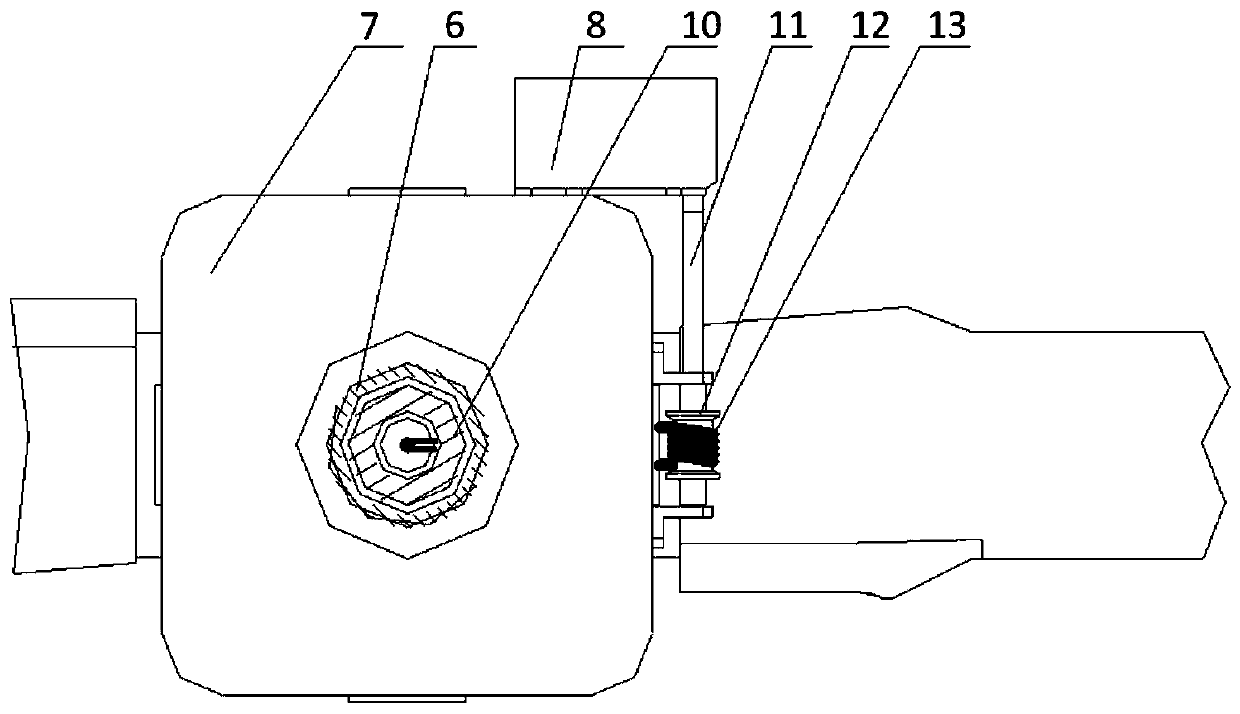

[0030] The central shaft 1 includes an upper central shaft 10, a coupling 20 and a lower central shaft 21; the upper central shaft 10 and the lower central shaft 21 are connected by a coupling 20, and the coupling 20 can be connected to the upper central shaft 10 and the lower central shaft 21. The lower central shaft 21 rotates; the middle of the coupling 20 is provided with a hollow cavity, the upper central shaft 10, and the lower central shaft 21 are all provided with hollow cavities, and the hollow cavities of the upper central shaft 10, the coupling 20 and the lower central shaft 21 are mutually connected;

[0031] The middle part of the upper central shaft 10 protrudes along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com