Medical isotope production reactor without compensation rod

A non-compensation, isotope technology, applied in the direction of transformation in nuclear reactors, can solve the problem of no way to change, and achieve the effect of reducing the initial load, simplifying the core structure and control system, and improving the backup reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

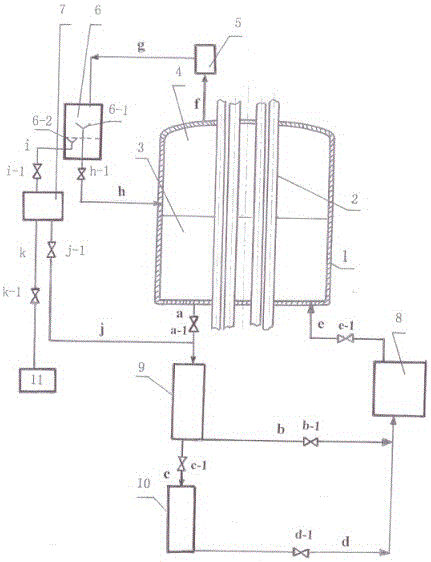

[0048] combined with figure 1 Describe in detail the core content involved in the design of a 200kW Medical Isotope Production Reactor (MIPR) by canceling the core compensating rods and simplifying the core structure of the present invention.

[0049] The core production structure of the 200kW medical isotope production reactor without compensation rods mainly includes:

[0050] Built-in core liquid UO 2 (NO 3 ) 2 The flat-bottomed cylindrical stainless steel core vessel 1 contains the core feed liquid 3 and the upper gas chamber 4. The core feed liquid 3 is radially divided into inner and outer areas, and the inner area is arranged with control rods 2: including two automatic adjustment rod guide tubes and Two safety rod conduits, the four conduits of these two types of control rods are sealed and welded to the upper cover and lower bottom of the core vessel 1, the conduits are filled with water, and the outer wall of the conduits is in contact with the fuel solution UO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com