Headstock device of high-speed internal grinding machine

An internal cylindrical grinding machine and headstock technology, which is applied to grinding machines, grinding workpiece supports, machine tools designed for grinding workpiece rotating surfaces, etc., can solve problems affecting grinding accuracy, insufficient processing speed, grinding efficiency and grinding efficiency. problems such as adverse effects on accuracy, to achieve the effects of a large range of machinable angles, ingenious and reasonable structural design, and improved machining accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

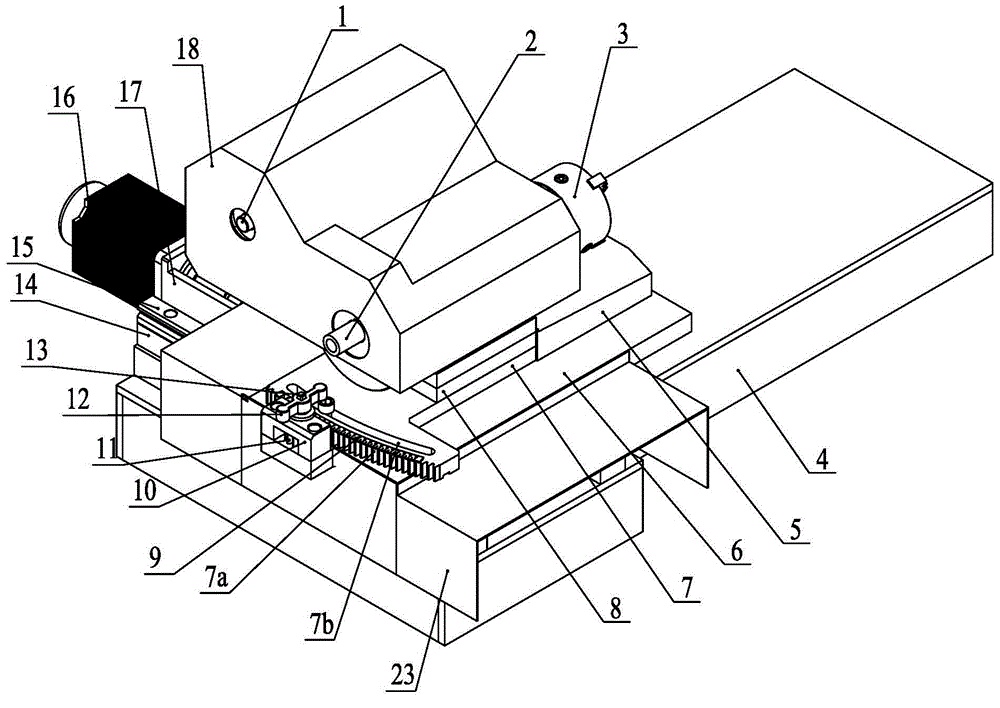

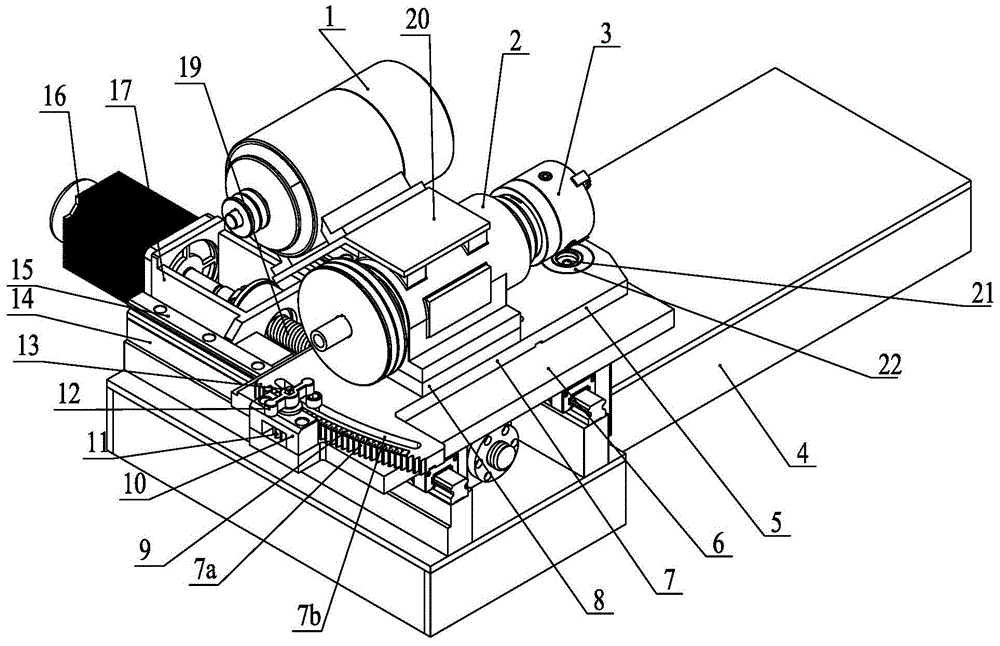

[0017] As shown in the figure: the headstock device of the high-speed internal grinding machine in the embodiment is installed on the workbench base 4, and the headstock device is mainly composed of a longitudinal line rail seat 14, a longitudinal linear slide rail 15, a plane rotary table of the headstock device, Longitudinal feed driving mechanism, spindle head 2, spindle motor 1, motor mounting frame 20 and chuck 3 are composed of two longitudinal line rail seats 14 arranged in parallel longitudinally and fixedly installed on the left end of the workbench base 4, two longitudinal line rail seats A longitudinal linear slide rail 15 is respectively installed on the top of the seat 14, and the plane rotary workbench of the headstock device is placed on the two longitudinal linear slide rails 15, and the slide on the plane rotary workbench of the headstock device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com