Multifunctional part milling machine

A multi-functional, part technology, applied in milling machines, milling machine equipment, metal processing machinery parts, etc., can solve the problems of low processing accuracy and low processing efficiency, and achieve the effect of improving processing efficiency, improving accuracy and reducing time waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

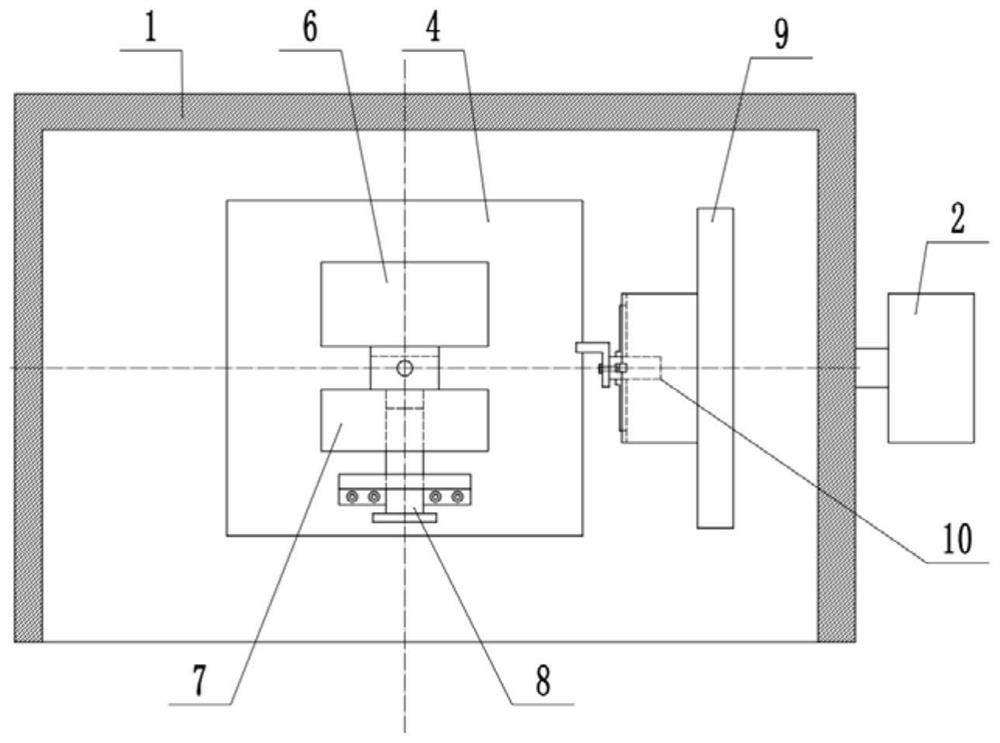

[0055] The difference between embodiment two and embodiment one is: as Figure 4 As shown, the left inner wall of the bed 1 is fixedly connected with a piston cylinder 11 by screws, and the piston cylinder 11 is horizontally slidably connected with a piston plate 12, and the piston plate 12 separates the piston cylinder 11 into a left chamber 13 and a right chamber independent of each other. The chamber 14, the left chamber 13 and the right chamber 14 are all connected with an air intake pipe communicating with the atmosphere, and a one-way air intake valve is installed on the air intake pipe; For the L-shaped first connecting rod 15, a clamping mechanism for assisting in clamping parts is provided on the transverse fixing seat, and a driving unit is provided between the right chamber 14 and the clamping mechanism.

[0056] combine Figure 4 and Figure 5 , in the present embodiment, the clamping mechanism includes two clamping blocks 16 facing to each other. The structures...

Embodiment 3

[0062] The difference between embodiment three and embodiment two is: as Figure 8 As shown, there is a communication pipe 24 connected between the two piston chambers on the same clamping mechanism. Through the communication of the communication pipe 24, the air pressures of the two piston chambers in the same clamping mechanism are equal, so that the two clamps The clamping force of the holding block 16 on the part is equal in size, so as to prevent the clamping block 16 on the left and right sides of the part from unequal in size against the part and cause the part to be unable to be stably fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com