Sander

A technology for sanding machines and sanding discs, which is applied in the field of sanding machines, and can solve the problems of grinding position deviation, long distance, high profile of sanding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

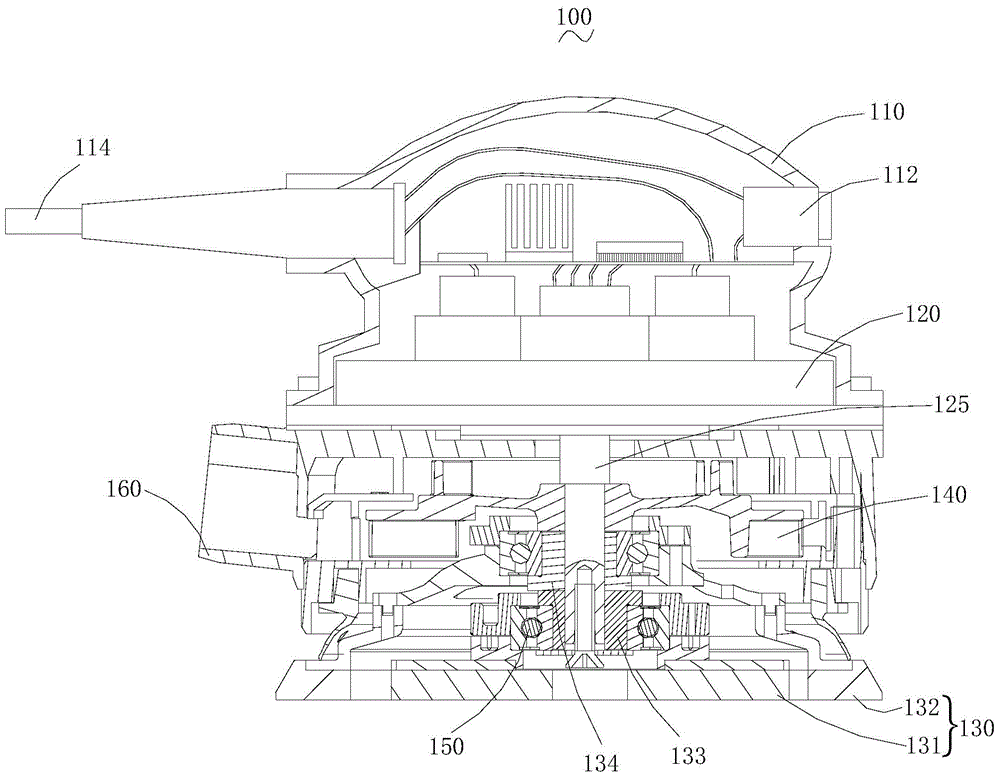

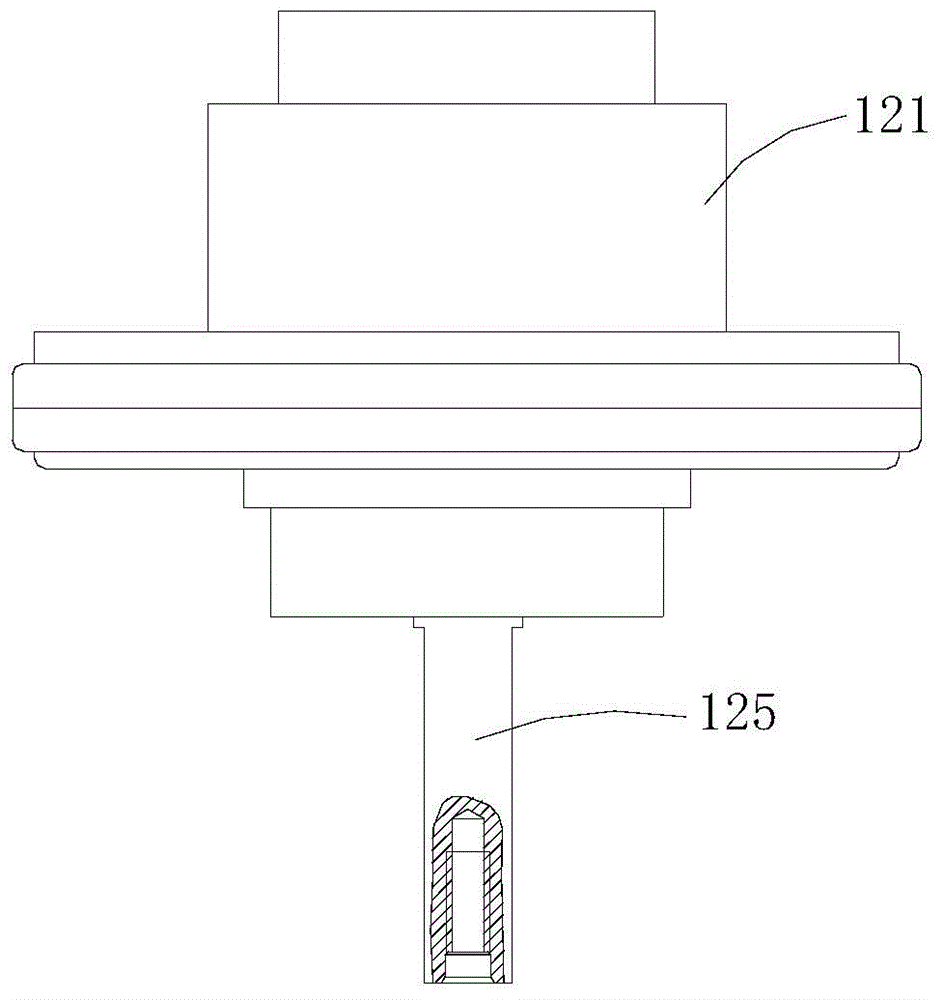

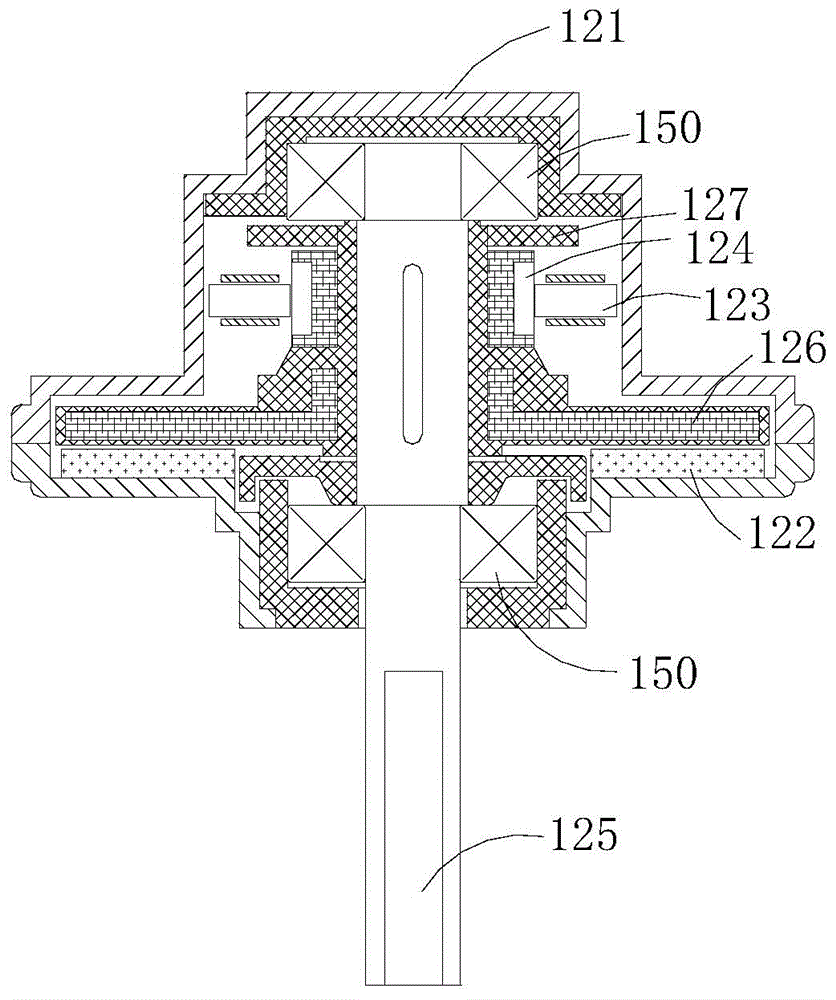

[0025] Please refer to figure 1 , an embodiment provides a sander 100 . The sander 100 includes a housing 110 , a motor disposed in the housing 110 , and a sanding disc 130 connected to the motor and driven by the motor to rotate for sanding. The shell 110 of the sander 100 is also provided with a fan 140 for cooling the sander 100 and sucking away the dust generated by the sander 100 . The shell 110 of the sander 100 is provided with a power cord 114 and a switch 112, the power cord 114 is connected to an external power supply to provide the sander 100 with the power required for work, and the switch 112 is used to control the opening of the sander 100 with off. The sand disc 130 of the sander 100 includes an inner sand disc 131 and an outer sand disc 132, the motor output shaft 125 drives the inner sand disc 131 to rotate through the inner sand disc eccentric shaft 133, and drives the outer sand disc through the outer sand disc eccentric shaft 134 132 spins. The inner sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com