Thermal Decomposition System of Reductant in Selective Catalytic Reduction Device

A reducing agent and selective technology, applied in the direction of exhaust device, muffler device, separation method, etc., can solve the problems of uncontrollable exhaust gas flow, reducing agent leakage, complicated piping structure, etc., to save production costs and equipment costs, reduce The effect of small size and space occupation, fuel cost and air pressure consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

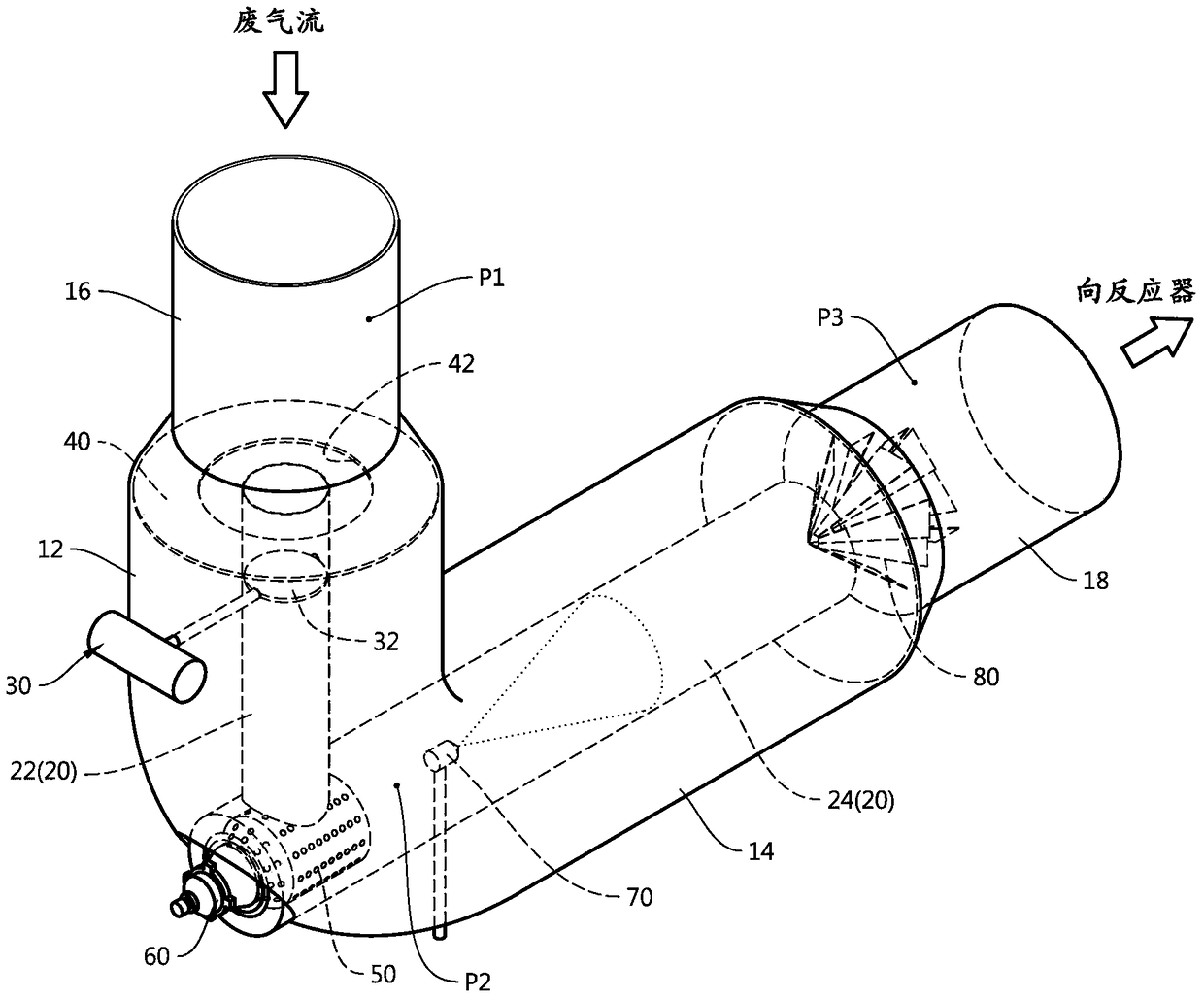

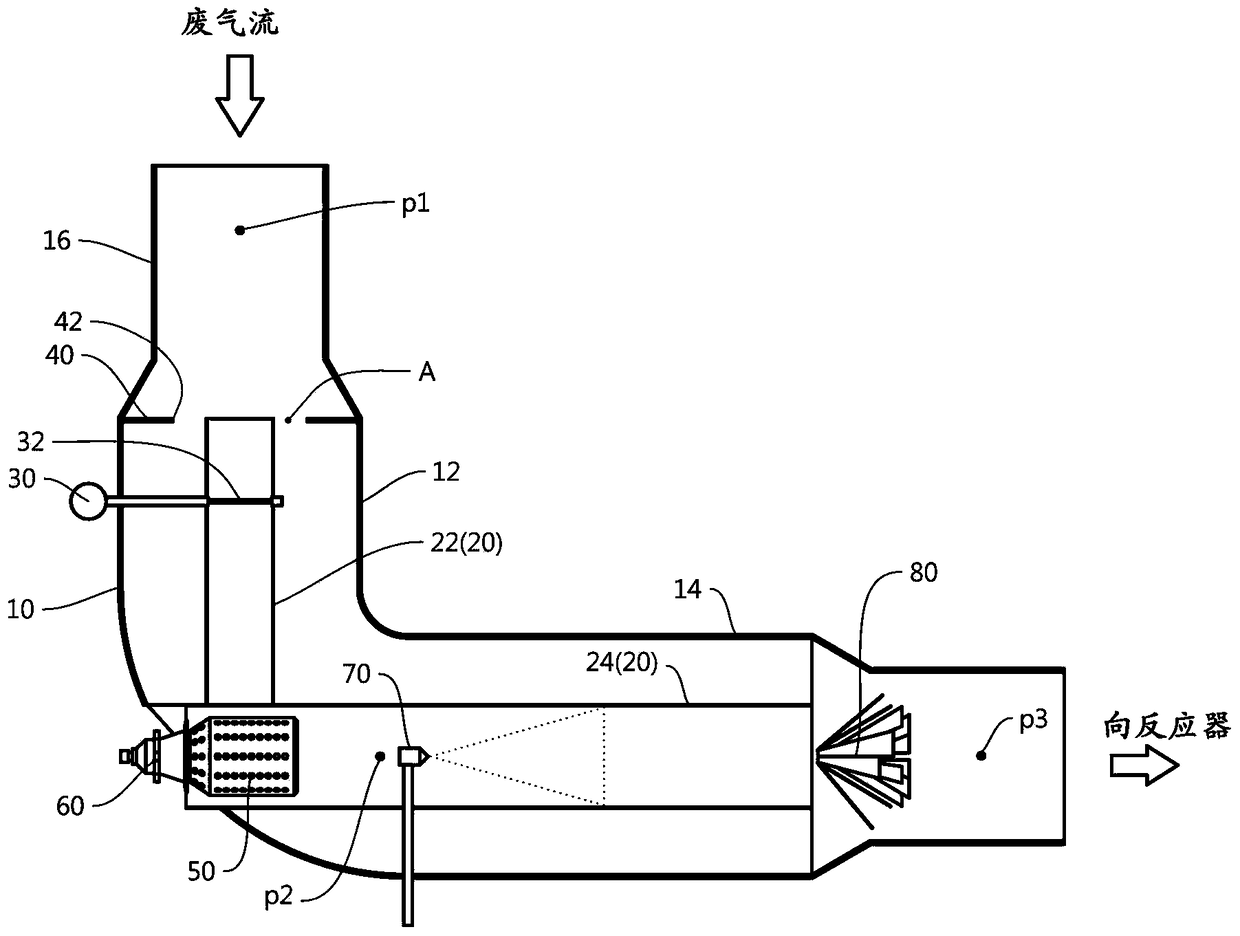

[0042] Reference and attachment Figure 1 With the detailed description of the embodiment, the advantages, features and methods for achieving the present invention are clarified.

[0043] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments described below are presented as examples to facilitate understanding of the present invention, and it should be understood that the present invention can be implemented in various modifications other than the embodiments described here. However, in describing the present invention, when it is judged that the specific description of related known functions or components may unnecessarily obscure the gist of the present invention, the detailed description and specific illustrations are omitted. In addition, in order to facilitate understanding of the invention, the drawings are not shown on an actual scale, and the size of some components may be shown exaggeratedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com