Rotary screen printing press

A technology of screen printing device and screen printing plate, applied in screen printing machine, rotary printing machine, printing and other directions, can solve problems such as lowering of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

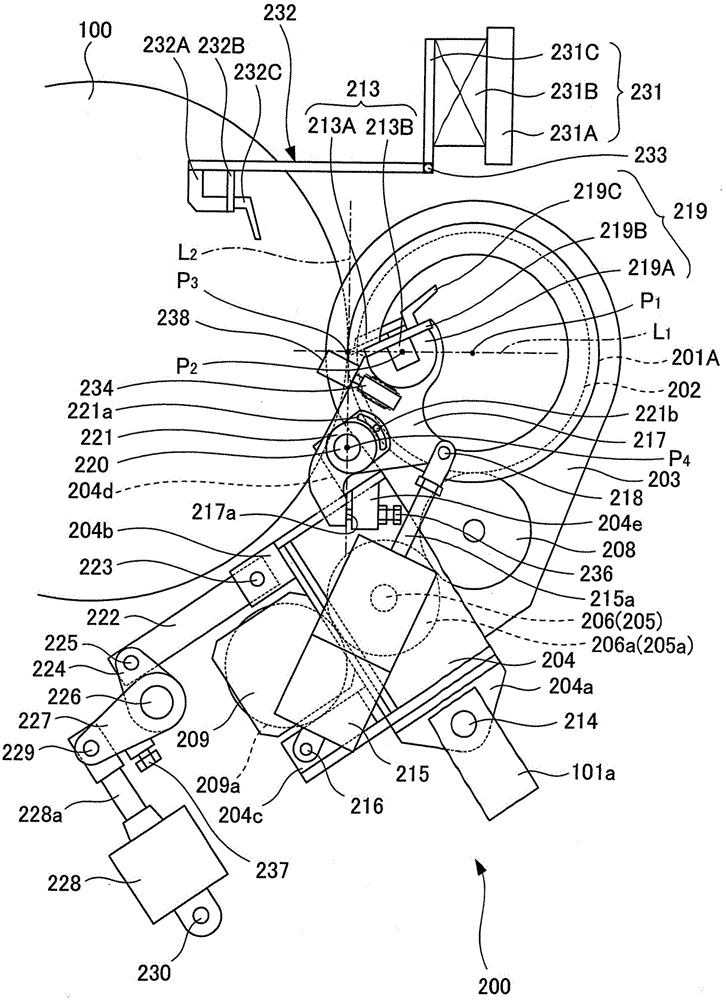

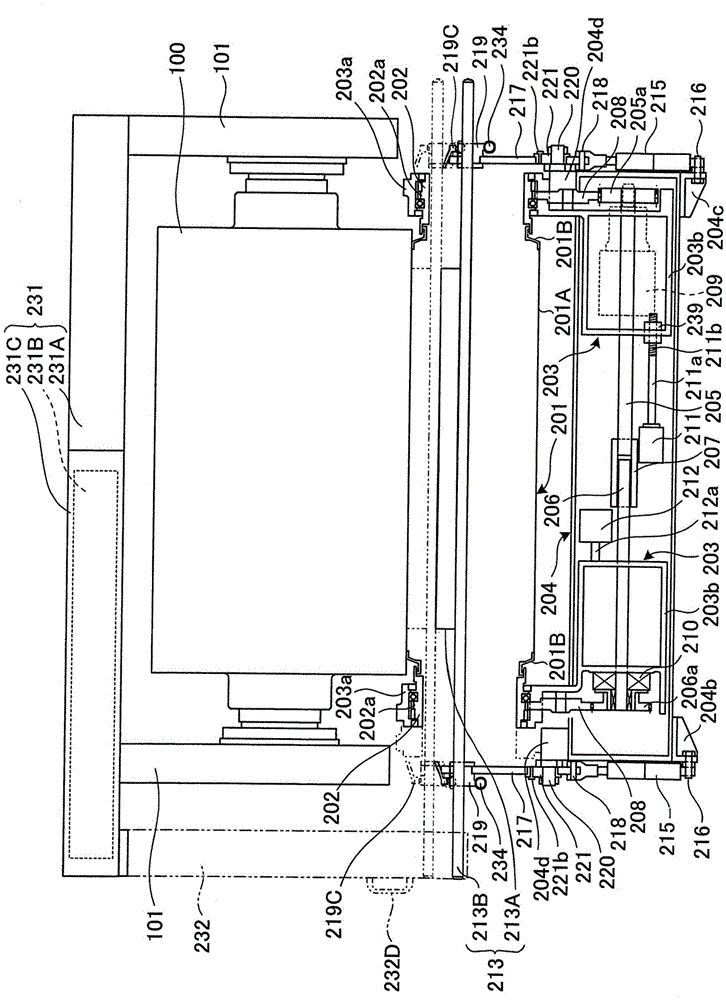

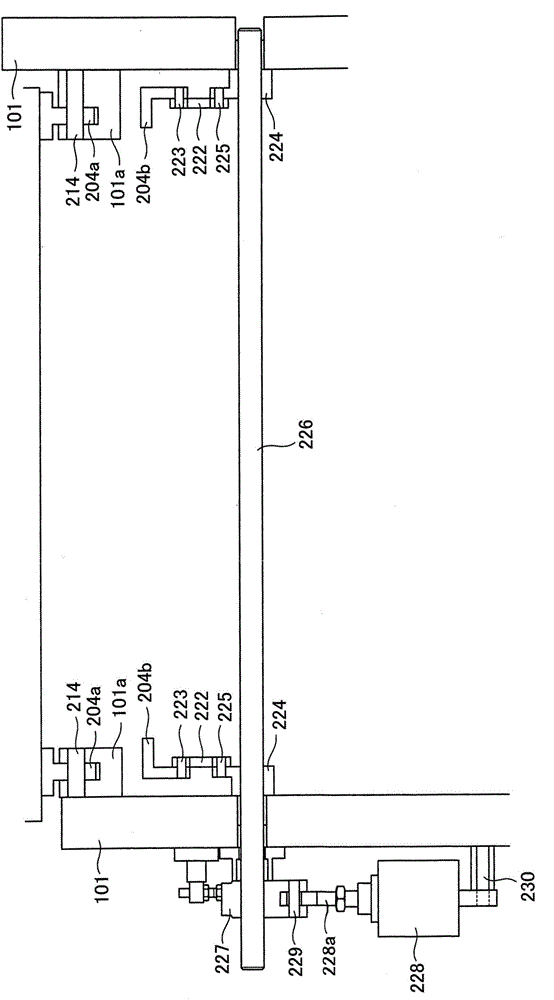

[0099] Hereinafter, a rotary screen printing device according to one embodiment of the present invention will be specifically described with reference to the drawings. In addition, the rotary screen printing apparatus of this embodiment is not limited to the structure shown below, Various changes are possible in the range which does not deviate from the inventive idea of this invention.

[0100] Such as figure 1 and figure 2 As shown, in this embodiment, the rotary screen printing device includes an impression cylinder 100 and a rotary screen device 200 .

[0101] The impression cylinder 100 is rotatably supported between left and right equipment frames 101 , 101 . Although not shown, notches extending in the axial direction of the impression cylinder 100 are formed on the outer peripheral surface of the impression cylinder 100 . A plurality of (for example, two locations in this embodiment) notches are formed at equal intervals along the circumferential direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com