Engine stall preventive method

An engine and power traction technology, which is applied in the field of applying a belt-type motor generator to prevent engine flameout, can solve problems such as insufficient engine speed, and achieve the effect of ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

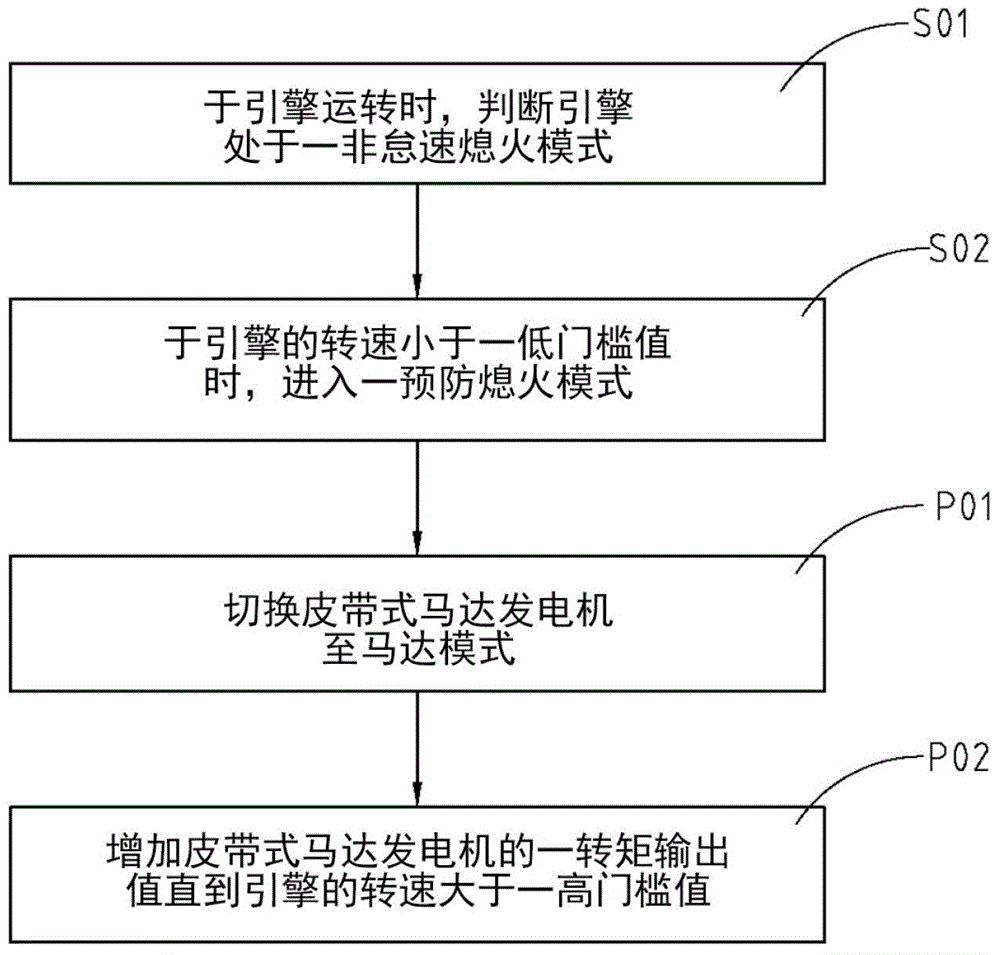

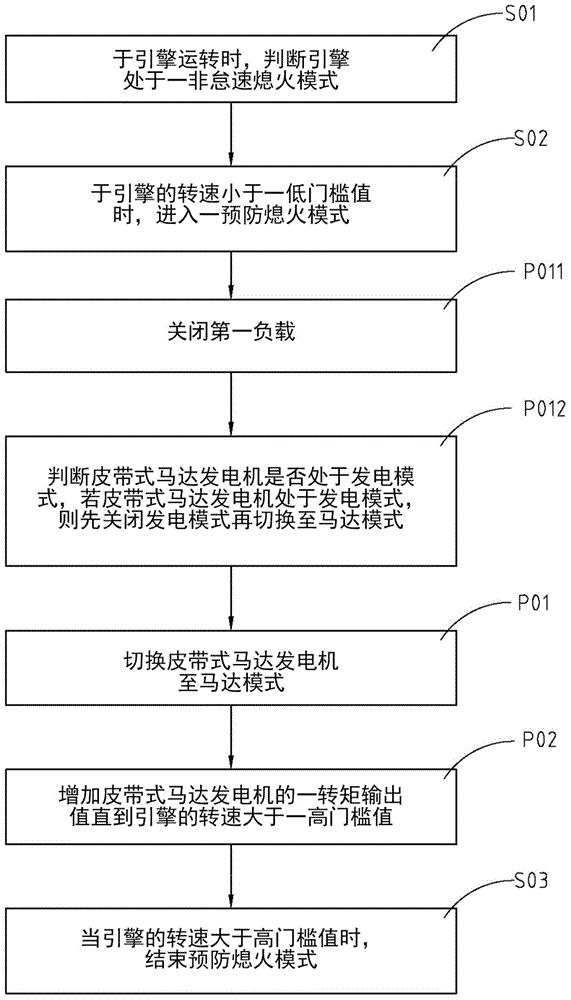

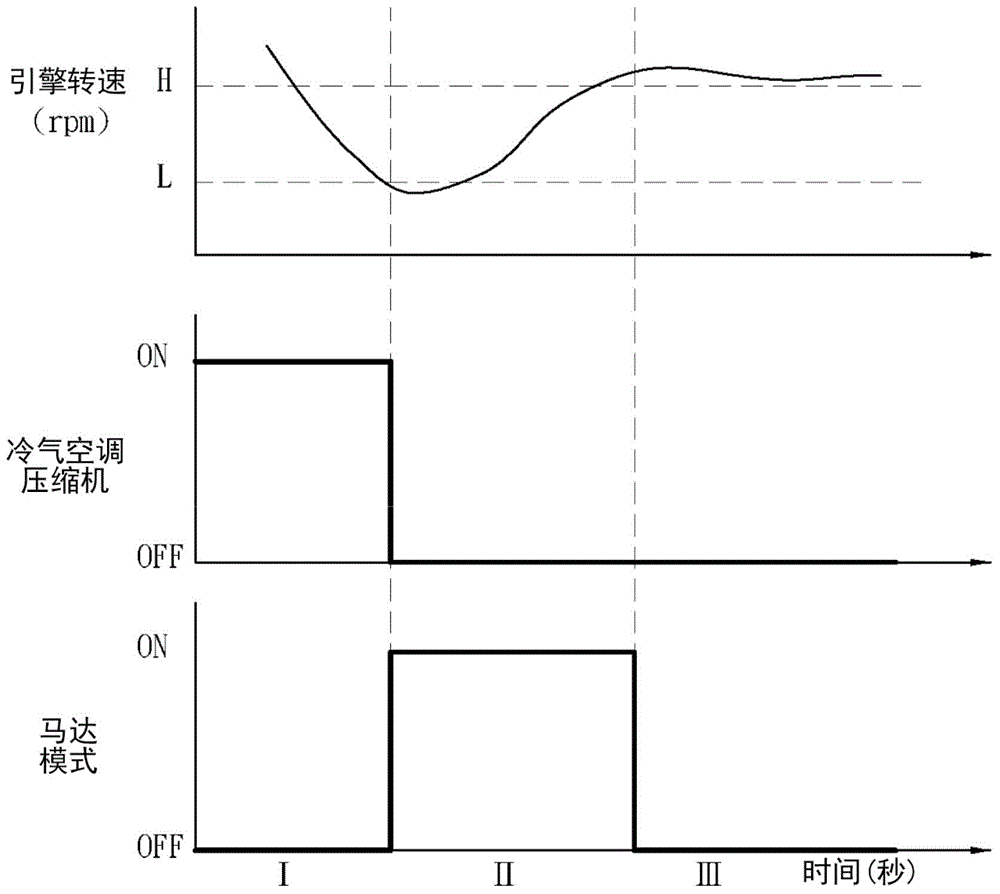

[0017] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0018] Please refer to figure 1 and figure 2 , which are schematic flowcharts (1) and (2) of the method for preventing engine flameout according to the first embodiment of the present invention, which specifically disclose the method for preventing engine flameout according to the first embodiment of the present invention. A belt-driven motor generator (Belt-Driven Starter Generator, BSG) is connected to an engine of a vehicle, and the belt-driven motor generator is connected to the engine for power. The vehicle may be, for example, a gasoline-electric hybrid vehicle, but the present invention is not limited thereto. The belt motor generator has a generator mode and a motor mode. In the power generation mode, the belt motor generator is driven by the engine power to generate electricity; while in the motor mode, the belt m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com