a burner

A burner and pipe body technology, applied in the field of cookers, to achieve low failure rate, improve ejection ability, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

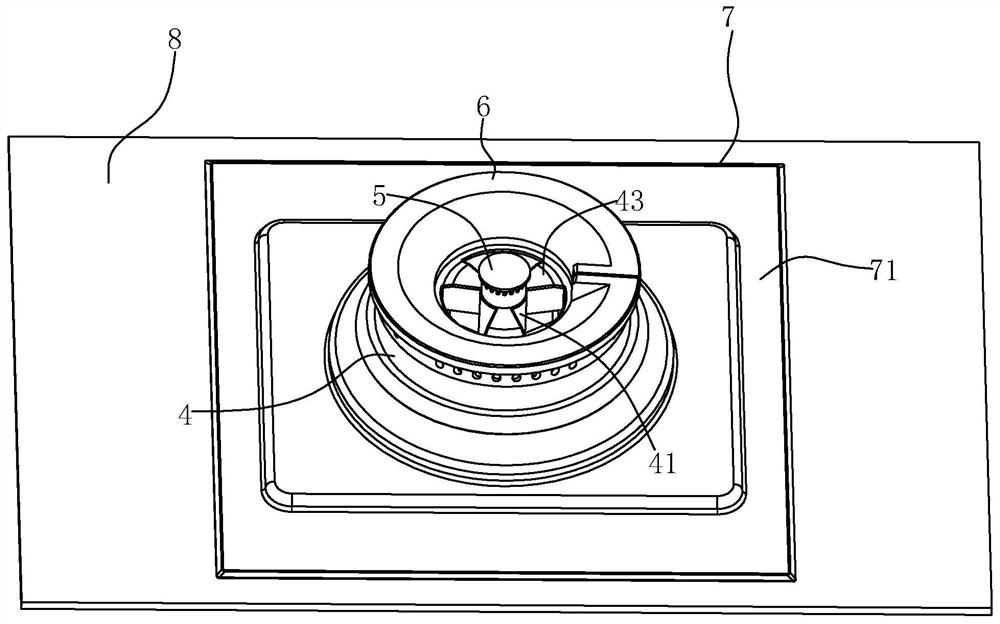

[0049]The burner can be installed in a cabinet for use. Usually, the upper surface of the cabinet has a panel 8, and the cabinet has an installation chassis on which the burner is installed.

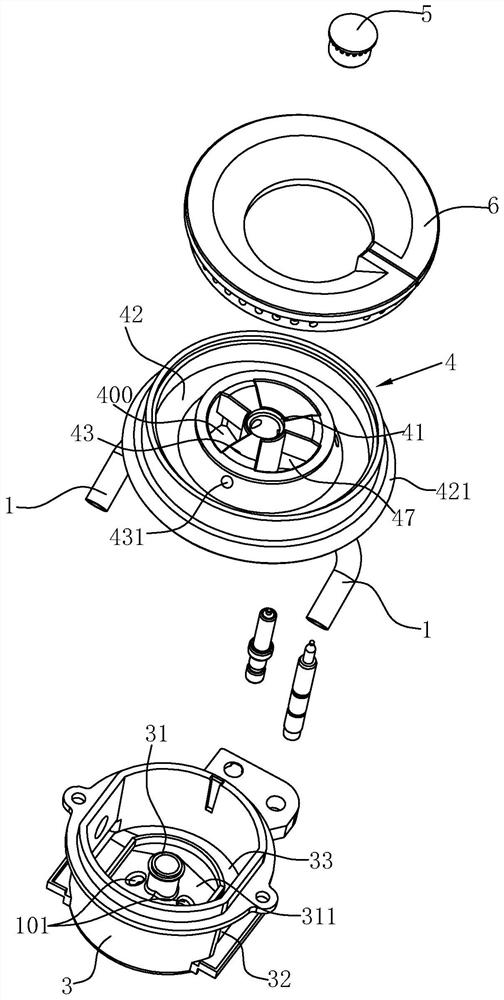

[0050] like Figure 1 to Figure 7 As shown, the burner in this embodiment includes a butt joint 1 , a nozzle 2 , a bottom cup 3 , a base 4 , an inner ring fire cover 5 , an outer ring fire cover 6 and a liquid pan 7 .

[0051] The liquid pan 7 is fixedly mounted on the panel 8 corresponding to the burner installation hole on the panel 8, and the liquid pan 7 also has an opening for the burner to be placed in. The liquid holding pan 7 in this embodiment has at least two stepped surfaces 71 , such that it is inclined downward from the inside to the outside along the radial direction.

[0052] The bottom cup 3 is cup-shaped as a whole, that is, the bottom cup 3 includes a bottom plate and a cup wall extending axially upward from the edge of the bottom plate. The installation edge is conne...

Embodiment 2

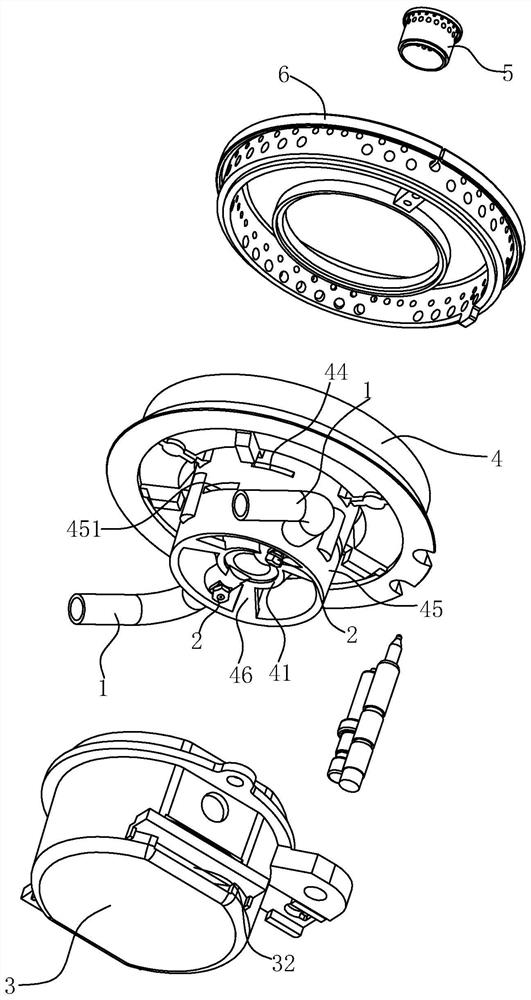

[0066] like Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the bottom of the liquid storage tank 400 gradually slopes downward along the radially inward direction, so that the bottom of the liquid storage tank 400 and the outer wall of the second tube body 41 A triangular liquid storage area is formed, which can store a certain amount of overflow liquid. An overflow hole 44 is defined at the lower end of the outer wall of the liquid storage tank 400 . In this way, the overflow that flows into the liquid storage tank 400 can first be collected in the triangular liquid storage area. Generally, when the amount of overflow is not large, the triangular liquid storage area can meet the storage of the overflow, which is convenient for storage. Post cleanup. When there is a large amount of overflow, in order to avoid the overflow from blocking the fire hole of the inner ring fire cover 5 and the flameout, when the overflow in the liquid storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com