Suspension type windproof rubber belt conveyor

A tape machine and suspension technology, applied in the field of transportation machinery, can solve the problems of tape breakage, loss, and fast wear, and achieve the effects of preventing deviation, prolonging service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

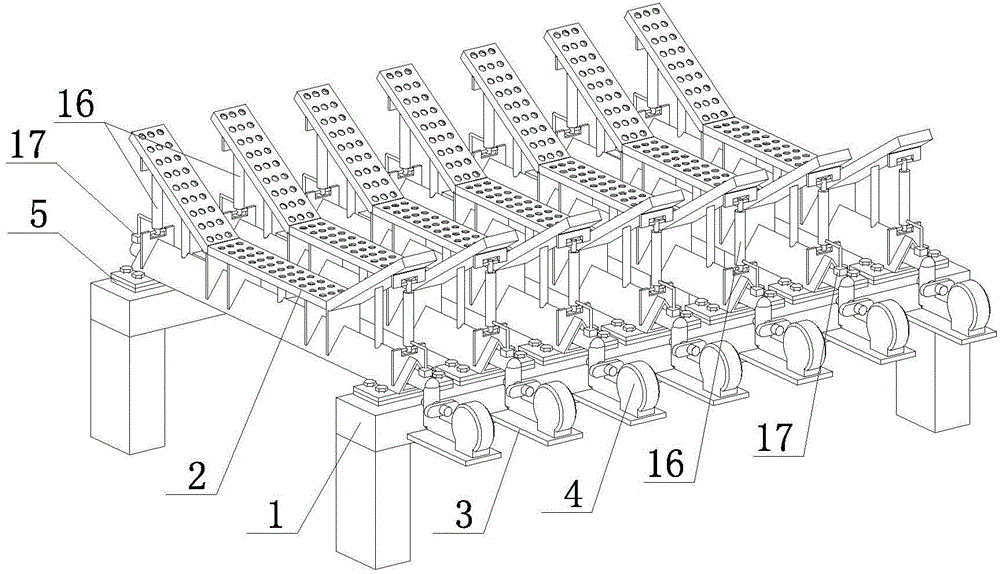

[0016] Embodiment 1 of the present invention: as figure 1 As shown, a suspension type windproof tape machine includes a roller group support 1 and a trough-type foldable air jet pallet group 2, and the trough-type foldable air jet pallet group 2 is evenly distributed on the roller group bracket 1, and the One side of the bracket 1 is provided with a fan supporting plate 3, and the fan supporting plate 3 is provided with a fan 4, and each trough-type foldable air jet supporting plate group 2 is connected with a fan 4 respectively; The bottom of each is provided with a shock absorber 5; the trough-type foldable air jet pallet group 2 is also provided with a gas push-pull rod 16, and the gas push-pull rod 16 is connected with the fan 4 through an electric valve 17.

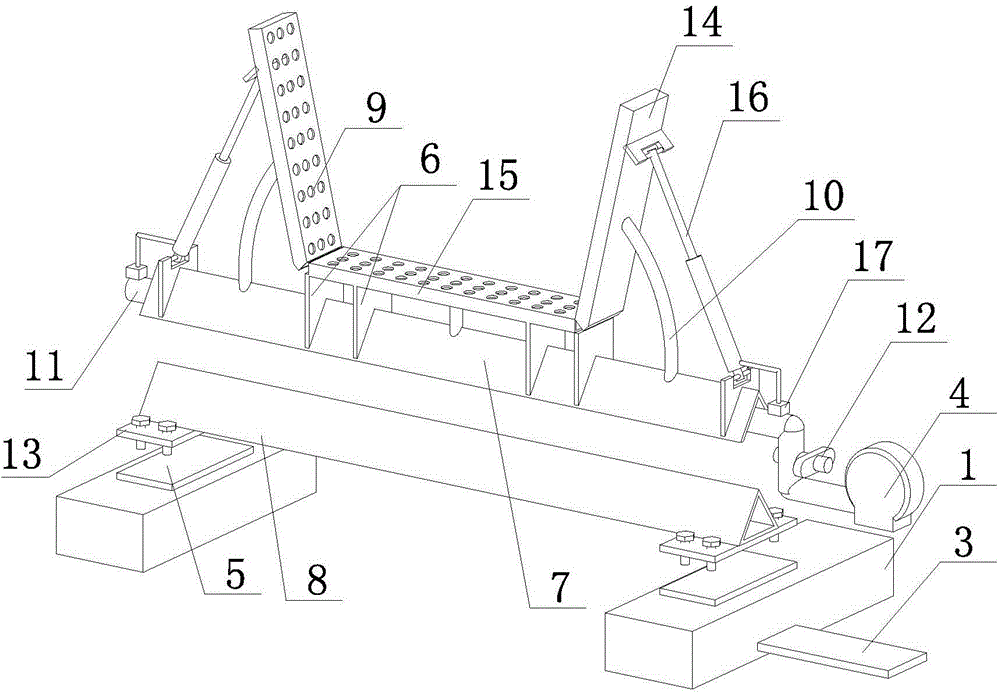

[0017] Such as figure 2 As shown, the trough-type foldable air jet pallet group 2 includes a horizontal air jet pallet 15, 2 side air jet pallets 14, a pallet support bar 6 and a slide bar 7, and the horizontal air...

Embodiment 2

[0019] Embodiment 2 of the present invention: as figure 1 As shown, a suspension type windproof tape machine includes a roller group support 1 and a trough-type foldable air jet pallet group 2, and the trough-type foldable air jet pallet group 2 is evenly distributed on the roller group bracket 1, and the One side of the bracket 1 is provided with a fan supporting plate 3, and the fan supporting plate 3 is provided with a fan 4, and each trough-type foldable air jet supporting plate group 2 is connected with a fan 4 respectively; The bottom of each is provided with a shock absorber 5; the trough-type foldable air jet pallet group 2 is also provided with a gas push-pull rod 16, and the gas push-pull rod 16 is connected with the fan 4 through an electric valve 17.

[0020] Such as figure 2 As shown, the trough-type foldable air jet pallet group 2 includes a horizontal air jet pallet 15, 2 side air jet pallets 14, a pallet support bar 6 and a slide bar 7, and the horizontal air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com