A kind of marine crane installation method

An installation method and technology of marine cranes, which are applied in cranes, ship accessories, transportation and packaging, etc., can solve the problems of increasing construction difficulty, huge size, and shortening construction time, so as to reduce construction difficulty, prevent ship shaking, and improve The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

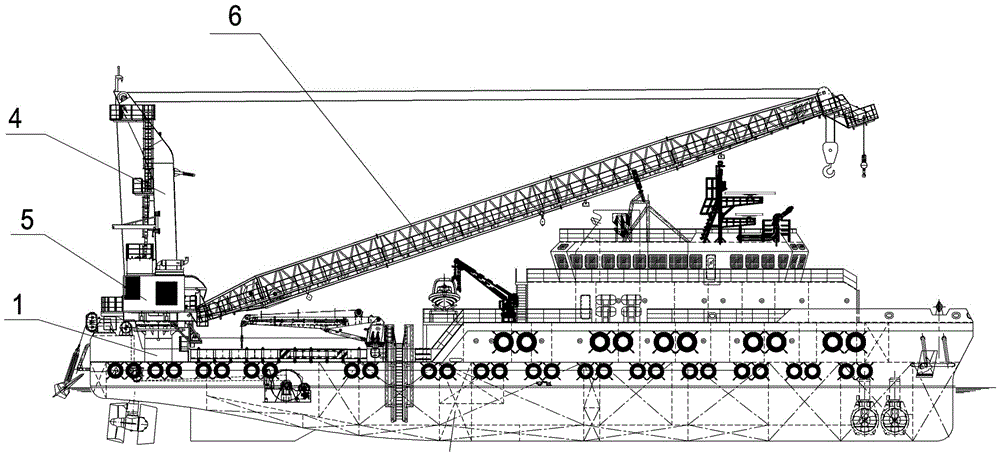

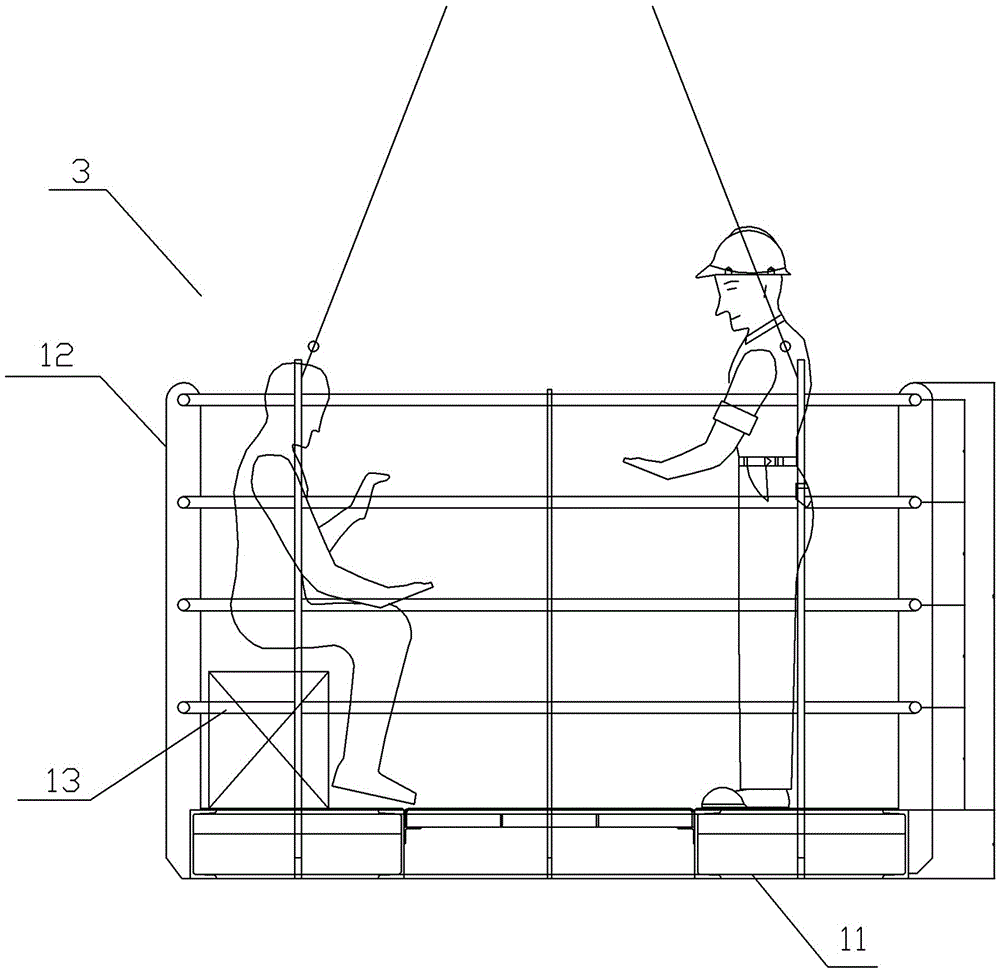

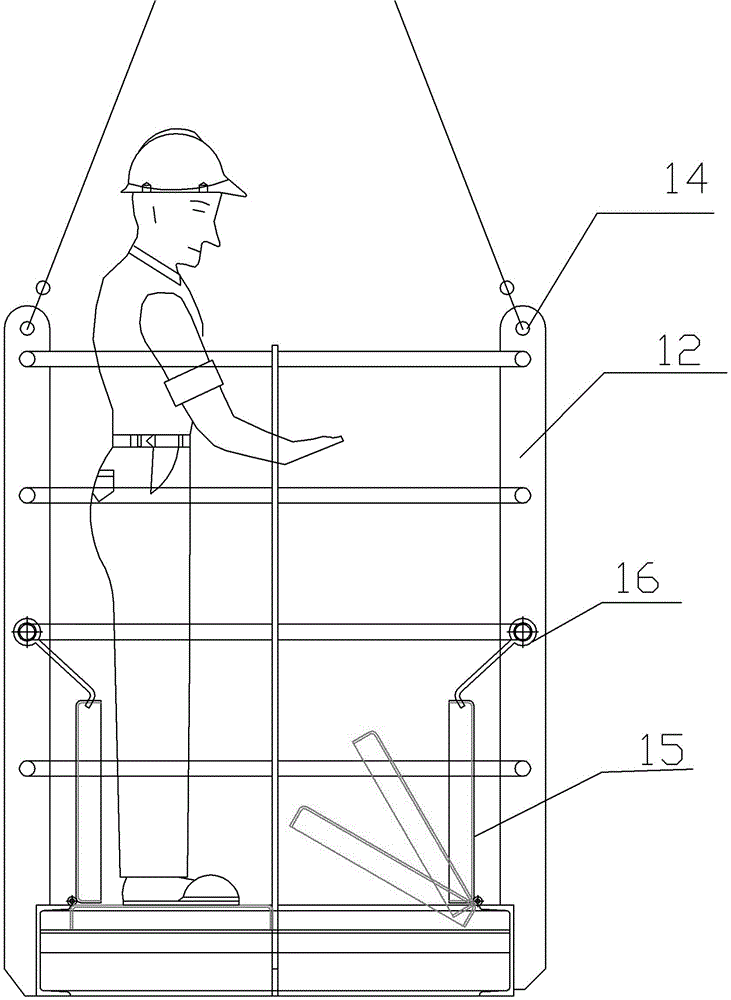

[0021] A method for installing a marine crane, such as figure 1 As shown, the steps are as follows: (1) Before the ship is launched, install the crane base 1 at the designated position on the ship, and the crane base can also be installed according to actual needs after the ship is launched; (2) After the ship is launched and docked at the dock Finally, the ship is fixed at the wharf by cables, and the general column is hoisted to the designated position on the ship by the lifting equipment; (3) the lifting equipment lifts the general column to the top of the crane base 1, so that the general column is vertically placed on the crane base 1, and the general column and the crane base 1 are welded together to complete the installation of the general column; (4) the hoisting equipment lifts the manned construction basket 3 to the top of the general column, and the construction basket 3 is fixed on the upper part of the general column, and load-bearing bearings are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com