Liquid crystal composition and liquid crystal display device comprising the liquid crystal composition

A technology of liquid crystal composition and liquid crystal display elements, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of liquid crystal conventional parameter performance changes, and has not formed a perfect theoretical explanation, etc., and achieves a wide nematic phase temperature range , high stability, large elastic constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

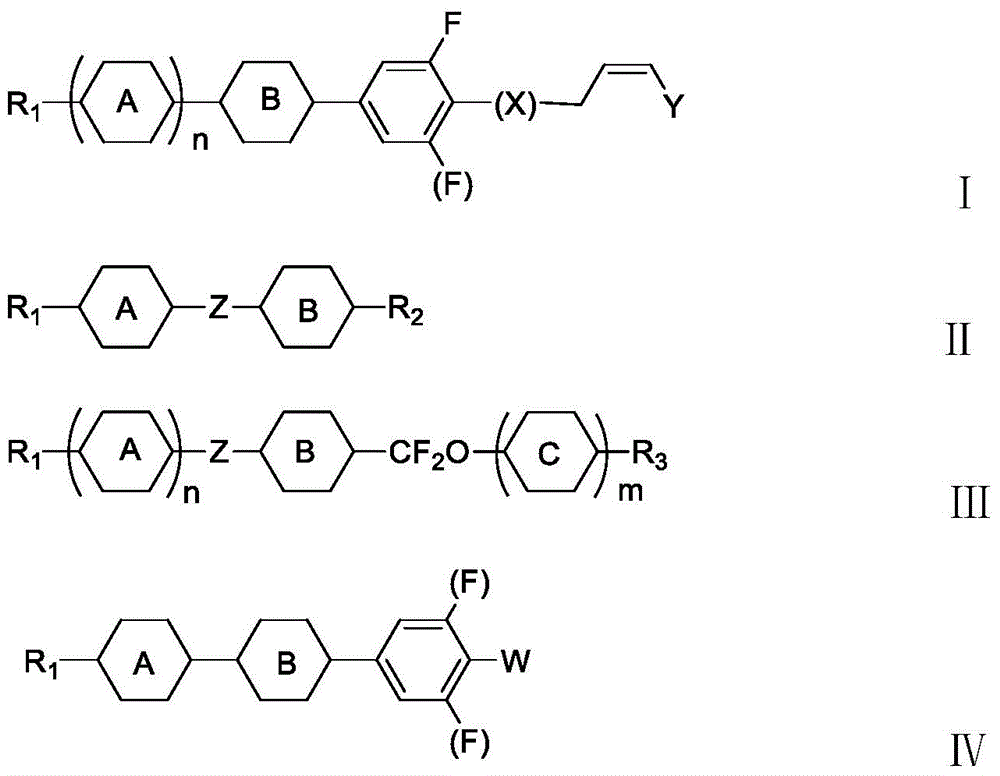

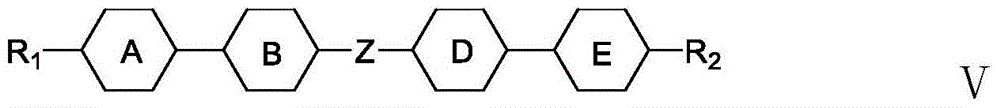

Method used

Image

Examples

Embodiment 1

[0093]

[0094] step one

[0095] Add 189g (0.58mol) 2′,3,5-trifluoro-4″-propyl-1,1′; 4′,1″-terphenyl, 1.7L tetrahydrofuran to a 3L three-necked flask, protect with N2, cool down to - 70°C. Add 256ml (0.64mol) butyllithium dropwise, dropwise time 0.5h, temperature control -65--75°C, after dropwise addition, keep warm for 0.5h, temperature control-65--75°C; dropwise 73.5 g (0.7mol) trimethyl borate, dropwise adding time 0.5h, temperature control -65--75°C, after dropwise addition, keep warm for 1h, temperature control-65--75°C.

[0096] Naturally warm up to -20°C. Pour the feed solution into aqueous hydrochloric acid until the pH is 2, stir for 5 minutes, separate the liquids, wash the aqueous phase with 500ml×2 ethyl acetate, combine the organic phases, wash the organic phase with 800ml×2 water, and dry over anhydrous sodium sulfate.

[0097] Concentrate the solvent, heat and dissolve the product in 600ML of petroleum ether, lower to normal temperature, filter with suc...

Embodiment 2

[0117]

[0118] step 1

[0119] Add 10g (0.03mol) 2′,3,5-trifluoro-4″-propyl-1,1′; 4′,1″-terphenyl, 120ml tetrahydrofuran into a 1L three-necked flask, protect with nitrogen, and cool down to -70 ℃.

[0120] Add 14.4ml (0.036mol) of butyllithium dropwise, keep warm for 30 minutes after adding, add DMF3.3g dropwise, keep warm for 1 hour. Naturally raise the temperature to -40°C, pour the reaction solution into 20g of hydrochloric acid and 100mL of water, separate the layers, extract the aqueous phase with 100mL of ethyl acetate, wash with water 150mL of 2, dry over anhydrous sodium sulfate, and spin dry 15g.

[0121] Add 30 g of petroleum ether to dissolve the product and recrystallize at -20°C, and filter with suction to obtain 9.8 g of product (2-a).

[0122] step 2

[0123]

[0124] Add 9.8g (0.028mol) (2-a), 150mL of methanol, and 50mL of water into a 500ml three-necked flask, add 3g of potassium borohydride in batches, heat the reaction solution to reflux, and r...

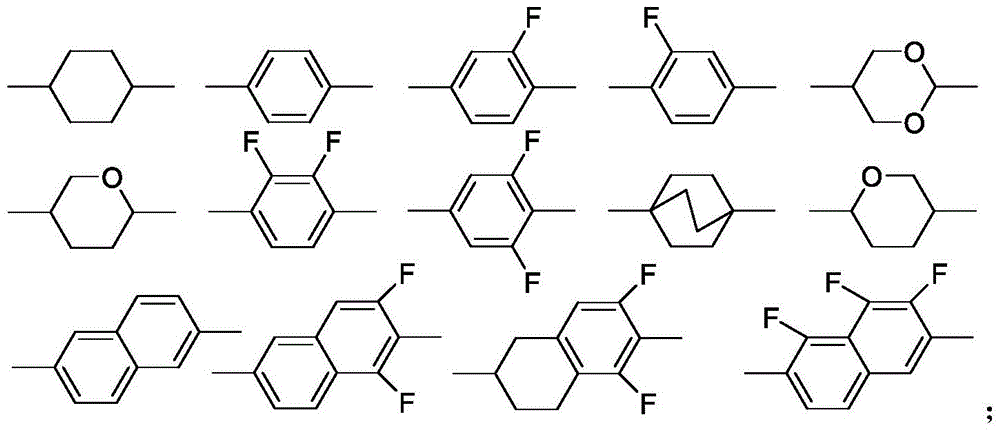

Embodiment 3

[0133]

[0134]

[0135] Δε[1KHz,20℃]: 11.5

[0136] Δn[589nm, 20°C]: 0.136

[0137] Cp: 97°C

[0138] gamma 1 [25°C]: 98mPa.s

[0139] K 11 , K 22 , K 33 :15.7,6.7,17.8

[0140] This liquid crystal composition has moderate Δε, large Δn, and very low γ 1 , suitable for fast response, low cell thickness TN, IPS, FFS-TFT display liquid crystal materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com